Taking the initiative: SLI and the next generation (part 2)by Stewart Money

|

| One would think that carefully considering options for integrating reusability and reducing life cycle costs into a system that will dominate exploration for decades to come would be an absolute necessity. |

This is the challenge that confronts any effort to reestablish the goals of Second Generation—“flexible, commercially produced reusable launch vehicles”—from where the US finds itself in 2011. Which, if one takes the conclusions of the 2009 Review of US Human Spaceflight Plans Committee (aka Augustine Committee) seriously, is in a nearly impossible situation. The committee’s finding that “no plan compatible with the FY 2010 budget profile permits human exploration to continue in any meaningful way” is, to say the least, disturbing. The source of the problem, “the cost of exploration is dominated by the costs of launch to low-Earth orbit and of in-space systems,” seems to be clear.

What is unclear, however, is why, despite concluding that high launch costs are essentially strangling the prospects for exploration that are “worthy of a great nation”, the committee report fails to mention any options for actually reducing launch costs, even while at the same time it suggests a number of credible options for reducing the costs of exploration hardware by limiting the overall launch mass requirements. A great nation might find it a worthy pursuit to attack the problem from both ends.

Given the fact that none of the heavy-lift launch vehicle options outlined in the Augustine Committee’s report—Shuttle-derived, DIRECT, Ares, or Super Heavy EELV—have actually been developed, much less the specific supporting infrastructure which drive so much of the recurring costs of any system, one would think that carefully considering options for integrating reusability and reducing life cycle costs into a system that will dominate exploration for decades to come would be an absolute necessity. To dismiss the concept altogether, presumably on the grounds that the partially reusable shuttle failed to reduce launch costs, is irresponsibly shortsighted. It is also an insult to the agency and contractor personnel who first sought to develop a different system, and then to improve the existing one, in pursuit of a more rational reusable system to begin with.

First, though, a bit of clarification on terminology. The term “first generation” refers to both NASA’s initial attempt at reusability, i.e. the Space Shuttle, and more generically, any other launch system that, like the shuttle, recovers some of the components and discards others. Under this definition, air-launched systems such as the Pegasus rocket could be technically considered first generation reusable as well. Following this nomenclature, a “Second Generation” vehicle would be any system that utilizes a two-stage-to-orbit architecture and fully recovers both stages. Third Generation references single-stage-to-orbit systems, and Fourth Generation, more exotic proposals such as maglev launchers and space elevators. The Fifth Generation is a little hazy, but if doesn’t include transporters, one can only wonder what sort of universe we live in.

Books chronicling space history are peppered with artist concepts of launch systems proposed over the years which, though rooted in serious thought, never stood a chance of taking to the air, and it is still the same today. There are many interesting proposals, a lesser number of which are actually credible and a much smaller number of which could fit within the existing technology and hardware base, are affordable, and meet existing needs.

Existing needs is the key. In 2001, at the time Second Generation was initiated, the Challenger accident, although not forgotten, was well in the past, and Columbia had yet to occur. In short, the shuttle still had a future with possible extensions beyond the current time frame. Second Generation would be a development program with some flexibility as to what was produced. Today, however, with the looming gap in US crew launch capabilities, at least in the minds of those who hold the purse strings, we have defined needs, which must be met now. Specifically, those needs are heavy lift for exploration, and possibly backup crew access to space in the event the Commercial Crew Development program fails. The landscape suggests any introduction of reusability will not have the luxury of a long development schedule.

In practical terms, then, re-embarking on the path to Second Generation would begin with analyzing the options for integrating First Generation, i.e. partial recovery, into existing systems or those under already development, without inadvertently precluding evolution towards a Second Generation system. Consequently, as far as NASA’s exploration ambitions are concerned for now at least, this means considering reusability as it would apply to shuttle-derived heavy lift, Ares, United Launch Alliance’s (ULA’s) Atlas or Delta rockets, as well as the Falcon 9. This is not to say that other systems, including entirely new ones, would not be an equally valid, perhaps even preferable, means to achieve the goals of Second Generation. Rather, the political environment, driven by the “gap”, would appear to make any entirely new start on fully reusable systems highly unlikely at this late hour.

| The landscape suggests any introduction of reusability will not have the luxury of a long development schedule. |

Not surprisingly after decades of frustration with existing systems, there is no lack of ideas on how to improve them. Recovery proposals for first stage boosters vary from the simple to the complex, and many have been around since the earliest days of spaceflight, and in some cases before. Reviewing the evolution of these proposals, particularly as they apply to existing systems, marks an appropriate starting point for considering options the Augustine Committee did not. One method of evaluation can be defined by the degree and manner in which hardware is recovered.

General considerations

The one unavoidable cost of any reusable booster is the engine system. Conventional expendable engines are designed with margins sufficient to adequately support several test firings, possible pad aborts, and one complete mission. For that one mission, however, they operate somewhere near the limit of their rated capacity and deliver the most performance for the least weight. The same engine installed on a reusable booster, by contrast, needs to be operated at substantially less capacity—around 75 percent—in order to maintain longevity for repeated re-use without complete breakdown and rebuild between firings. Consequently, a comparable capacity reusable booster will require either more or higher-rated engines to achieve the same lift performance as an expendable operating at redline.

In all instances, however, there is no getting around the fact that any system installed on a first-stage booster which facilitates returning all or part of the vehicle for re-use is an exercise in tradeoffs. Recovery necessarily detracts from that booster’s launch efficiency. This, in turn, requires a proportionately smaller payload for a same size booster, or a larger booster for the same sized payload, or the addition of extra strap-on boosters to compensate for the extra weight. Furthermore, this tradeoff gets increasingly difficult as one installs systems to return the booster back to the launch pad in a condition ready to re-fly.

Engine/avionics parachute recovery

One of the simplest proposals is to look past the fuel tanks and supporting structure, and focus instead on recovering the engines and avionics by parachute or parafoil. The logic is fairly simple in that the engines represent a substantial portion of the overall cost of the vehicle, and as such offer significant savings with lower overall investment in recovery apparatus. This method has historically been associated with very large rockets, particularly cargo variants derived from the shuttle system, where a low launch rate and high payload capacity combined with a large tank structure argue against considering full recovery. As such, it is a technique with obvious implications for any of the proposed HLV architectures, including shuttle sidemount, in-line (DIRECT), or Ares V/Ares Lite.

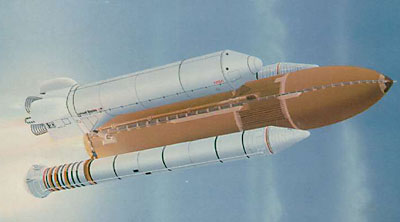

In fact, well into shuttle development but prior to its first flight, as early as 1977, NASA and contractors were already looking at possible ways to improve the system performance. One Boeing proposal called for removing the side-mounted boosters entirely and placing the shuttle and external tank on top of a hydrocarbon first stage. In this configuration, the first stage would be recovered by a parachute and retrorocket combination. While this represented a radical departure from the existing system architecture, and was in fact similar to other pre-development proposals featuring the Saturn V first stage as a booster, the timing itself was interesting, and indicative of the fact that some elements within NASA were never really comfortable with the shuttle system as configured, and would repeatedly look at options to change it—all to no avail.

Once actual flight operations began in 1981, planners began to pay serious attention to the development of a cargo-only version of the system, what would later come to be known as Shuttle-C. The same concept forms the basis for what Congress is insisting NASA undertake today as a shuttle-derived heavy lift vehicle. What bears emphasis is that NASA-sponsored contractor studies all initially incorporated plans for recovering, at a minimum, the Space Shuttle Main Engines (SSMEs). It was only later, as the agency ran out of time and money, and sought to field the cargo system that it could launch soonest, that planners considered a fully expendable alternative.

| It should perhaps be a point of concern to heavy lift planners that the Delta IV is the least affordable of current EELV’s. |

The initial concept, as developed by Martin Marietta, called for placing the engines and avionics in a cone shaped recoverable pod that would parachute back to Earth after thrust termination. Landing would be accomplished horizontally with a quadropod structure, which allowed for a skidding touchdown to reduce shock. In some of the proposals, the carrier vessel was recovered as well, whereas in others it was left to burn up on re-entry. One proposal, no longer achievable, called for quick disconnect fittings to leave the engines in orbit so they could be retrieved later by a shuttle 0rbiter returning home empty.

In the end, all work on Shuttle-C was terminated when the US elected to cancel its primary payload, Space Station Freedom. In retrospect, what was considered as the chief impediment to a number of the alternatives studied, particularly those that placed the engine thrust assembly under the tank (inline), was the fact that they would require modification to the existing shuttle launch facilities. Other concerns were that some cargo vehicle configurations would interfere with orbiter processing operations. As there will soon no longer be an existing system to worry about, the case for dismissing integration of reusable components on these grounds is no longer valid.

Engine recovery is also the subject of a current (2008) proposal regarding the Atlas V booster, because of the fact that it is powered by the Russian RD-180, which in its original form was designed for up to 10 re-flights. In this case, the jettisoned Booster Recovery Module would be initially slowed by a hypersonic decelerator and then deploy a controllable parafoil with trailing recovery line. The entire package would then be intercepted by aerial capture utilizing a helicopter to prevent the shock and contamination of an ocean landing. While never applied to parachuting rocket engines, aerial recovery along the lines proposed is an accomplished fact. Besides the obvious application to the existing Atlas V, this proposal also has clear relevance to a potential Atlas V heavy or Super Heavy configuration if selected as the preferred alternative for heavy lift. In both cases, a successful engine recovery technique would have a profound effect due to the potential recovery of all three engine structures in the common core/strap-on booster configuration.

The Atlas V’s stable mate in ULA offering, the Boeing Delta IV, would also be a possible candidate for engine recovery, if only the engine were reusable. This is somewhat ironic considering the fact that Delta IV’s RS-68 engine is itself an expendable derivative of the SSME. Now pegged as the baseline engine in the Ares V/Ares Lite booster proposals, it should perhaps be a point of concern to heavy lift planners that the Delta IV is the least affordable of current EELV’s.

It is perhaps unfortunate, then, that Boeing’s original proposal for the EELV competition was a new booster based on the SSME, featuring a parachute recoverable engine pod. As part of its bid preparation, the company reportedly dunked an SSME into the Mississippi River protected by a retractable skirt, dried it off, and successfully re-fired the engine. The test confirmed, at least in a limited manner, that water recovery of SSME was feasible. No word on whether it was used to prepare the world’s most expensive recipe for southern fried catfish.

Booster parachute recovery

The second recovery category involves landing a booster’s entire first stage by parachute or parafoil. While we are all familiar with the parachute recovery of the shuttle’s solid rocket boosters, recovering liquid-fueled boosters is an altogether different challenge. The SRBs are comprised of comparatively sturdy steel casings, whereas liquid fuel boosters are not. The design factors that make an otherwise expendable launch vehicle what it is—as lightweight as possible to achieve its goal—also make it highly susceptible to the loads imposed by parachute recovery and impact with any hard surface, such as the ocean.

Nevertheless, this is the goal SpaceX is apparently pursuing for the Falcon 9, though from parsing the few specific statements the company has made regarding reusability, it may be that that the company’s initial goal is to recover the booster for the purpose of re-using the engine cluster only, at least as a step towards full re-use of the first stage. Given the company’s necessary prioritization of actually launching the vehicle in the first place, it is not that surprising that SpaceX’s first two attempts at recovering the Falcon 9 have ended poorly.

While SpaceX appears to be the first company to actually attempt recovery of its liquid-fueled boosters, it is a goal shuttle planners had hoped to undertake at some point. Throughout the history of the shuttle program, from development-era designs to a series of studies conducted over the past 30 years, both NASA and its contractors considered liquid-fueled, parachute-recovered boosters (as well as flyback boosters) as an alternative to the problematical SRBs.

| The NK-33 engines originally intended for the K-1 are incorporated in the current COTS winner Orbital Science Corporation’s Taurus II rocket—but apparently, like so many RD-180s, their future lies at the bottom of the ocean. |

As part of the same 1981 shuttle upgrade study that produced the cargo version recoverable engine pod, Martin Marietta also looked at substituting fully recoverable liquid-fueled boosters for both versions. In this case, the strap-on booster’s engines were standard SSMEs that were protected on water landing by a set of clamshell doors that sealed after thrust termination. The boosters would be recovered by parachute with the aid of flotation, and like the SRBs they would replace, would be towed back to Port Canaveral. Other variations looked at possible substitution of entirely new methane or propane engines. A conclusion at the time, that either these options could offer significantly lower long-term operating costs, seems to have been ignored, but perhaps still bears consideration today as well.

In all cases, the rationale for pursuing such a significant hardware change for both 0rbiter and cargo configurations was to increase both flight and ground handling safety, increase lift capacity, and lower operating costs. Even with the orbiter out of the picture, these objectives are hardly less valid today.

One vehicle that was partially completed but never flew, the Kistler K-1, warrants discussion as well. Designed as a fully-reusable two-stage-to-orbit liquid-fueled booster, the K-1 was to utilize parachute landing in water accompanied by an airbag system to soften impact and provide flotation for recovery. Rocketplane Kistler, as some may recall, was an original Commercial Orbital Transportation Services (COTS) winner, but lost its funded Space Act Agreement when it was unable to meet matching private fundraising requirements. While RpK’s business development approach did not pay off (see “The gap in NewSpace business plans”, The Space Review, July 12, 2010), the presence of respected Apollo veterans lent credence to the pursuit of reusability upon which the K-1 vehicle itself was based. Now only a historical footnote, it is worth mentioning the K-1 utilized Russian NK-33 engines salvaged from the Soviet lunar program. These same engines are incorporated in the current COTS winner Orbital Science Corporation’s Taurus II rocket—but apparently, like so many RD-180s, their future lies at the bottom of the ocean.