Riding Titans (part 1)by Dwayne A. Day

|

| Gemini has long been the Jan Brady of the American space program, the ignored middle child. But Gemini also represented the point in the Space Race when the United States shot past its rival and never looked back. |

Bill Barry, NASA’s chief historian, and Mike Neufeld, the Smithsonian curator with responsibility for the museum’s Gemini artifacts, gave the opening talks about the origins and goals of the program. Neufeld explained that Gemini started after the Apollo program was underway, in effect making it NASA’s third human spacecraft. Originally known as Mercury Mark II, it was a scaled-up version of Mercury, capable of carrying two astronauts and operating for a longer period of time. Gemini proved to be an important interim step not only because it developed procedures later used on Apollo, but because Apollo was such a dramatic increase in size and capability. Neufeld showed drawings of Mercury and Gemini next to an Apollo Command Service Module/Lunar Module stack as well as Gemini’s Titan II rocket dwarfed by the Saturn V. Gemini was the footstep up to the technological heights of Apollo.

The astronaut

Gemini 11 astronaut Dick Gordon was the next speaker and he recounted his mission, which came late in the Gemini program. The primary goal of the Gemini 11 mission was a quick rendezvous. The ascent stage for the Lunar Module had a lifetime of about nine hours. Rendezvous with the Command Module took around two hours. NASA wanted to see if it was possible—using more fuel—to fly directly up to rendezvous rather than waiting several orbits to gradually get closer. Dick Gordon and commander Charles “Pete” Conrad proved that it was.

Gordon recounted that launching atop a Titan II rocket, which had originally been designed as an ICBM, was dramatic. The rocket leapt off the pad and sped straight to orbit in seven minutes, all the time subjecting its astronauts to very powerful g forces. He remembered late in the ascent sitting pressed back into his seat wondering “Isn’t this sucker gonna quit?”

“It’s dynamic…” Gordon later emphasized. Then again, everything about spaceflight is dynamic. “Nothing occurs in spaceflight unless there’s an explosion!” he joked. He found the Saturn V—he flew on Apollo 12—to be a gentler ride. He was later scheduled to command Apollo 18, which never flew.

Gordon and several others noted that it was not only the Titan II that moved fast—the entire program was operating at a fast pace, with launches every couple of months. “It seemed like we were passing each other going to and from the pad,” Gordon remembered. In retrospect, he thinks that the pace was too fast and that NASA was not taking sufficient time to learn the lessons from each mission before jumping on to the next one. But with Apollo charging ahead, in many ways NASA needed to get Gemini done and over with.

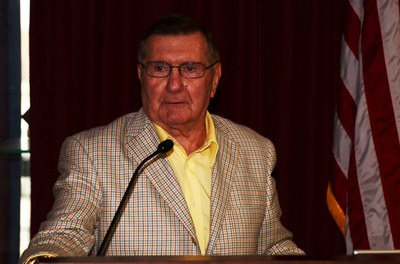

Dick Gordon, who flew on Gemini 11, talks about his experiences with the program. (credit: Master Sgt. Ed Bard, MDANG) |

The engineers

The next speaker was Martin engineer Don Caldwell. Caldwell had worked on a jet seaplane project and then Vanguard before getting assigned to Gemini. His area of expertise was propulsion and he was responsible for the Titan II rocket engines. Martin was then manufacturing the Titan II ICBM in Denver. Because the company did not want to interrupt its production lines with the relatively small NASA order they had the Middle River, Maryland plant produce the Titan II rockets. The Denver factory would ship parts to Middle River for assembly.

| Gordon remembered late in the ascent sitting pressed back into his seat wondering “Isn’t this sucker gonna quit?” |

According to Caldwell, his job was to “clean up all the… stuff that Martin was selling to the Air Force.” In his opinion the Denver factory was delivering poor quality missiles to the Air Force and the stuff that showed up in Middle River was substandard. The first Titan II engine that showed up at Middle River had a lot of weld repairs and had to be sent back to Denver. The next two were not much better. Soon they sent people to Denver to check the work before it ever got sent to Middle River, and Caldwell implied that there was a shakeup at the Denver plant in response to the quality problems.

The exhaust bells on the Titan II engines were made of tubes that were pumped with oxidizer for cooling. According to Caldwell, there were a lot of cracked tubes. A cracked tube would lead to a side force to the rocket and a kick to one side in flight. For an ICBM this might not have been a problem, assuming that the control system could compensate, but for a human-rated rocket it was unacceptable.

The solution was for Caldwell to assemble a team and X-ray all of the welds on the engine bells, a process that he called tedious and laborious. It was “not a whole lot of glory,” he said, but it was necessary. Fortunately, it worked and they had no propulsion anomalies.

There was one mission where the rocket experienced a surprising event. Apparently the first stage put the rocket too high and upon separation the second stage pitched the vehicle over hard to bring it back onto the proper trajectory. “All hell broke loose” on the ground, Caldwell said, and company leadership wanted to know what had happened.

The cause was not hard to find. The Titan II’s first stage was designed to burn until all of the fuel was exhausted. But there was no way to determine how much fuel was being burned at engine startup, so the launch managers had tended to overfill the tanks just to be sure. Caldwell invented a device for determining how much fuel was burned upon startup and he patented it. But because he did the work on company time Martin took the patent and gave Caldwell a $25 check.

Caldwell was followed by Martin employee Harry Mettee, who started by recounting some of Martin’s history. The company had built tens of thousands of bombers for the Army Air Forces during World War II, churning most of them out at the sprawling Middle River factory. In fact, the first highway cloverleaf in the United States was built at Middle River to accommodate the large workforce.

In the 1950s the company was a lot smaller, but had a major contract making a jet seaplane for the US Navy. When that project was canceled, the company contracted dramatically and the leadership decided to focus on missiles rather than airplanes. Because the Cold War made the coasts more vulnerable, Martin shifted its missile work primarily to Denver. The company later moved some other work to Orlando.

| “Most of us would have blown up before we would have ejected,” Gordon said, indicating that the astronauts did not trust the ejection seats. “They were scary things.” |

From a high of 53,000 workers during World War II, the Middle River plant had only 600 people by the early 1960s. Almost all of the engineering and design work was gone and the only real work left at Middle River was fabrication and construction. The company kept alive with subcontracting to other companies like Boeing and General Electric, building components for their aircraft. They were busy. “You didn’t have any downtime,” Mettee said. Some of this proved lucrative for the small Maryland branch, such as making components for GE’s aircraft engines. But Mettee noted that one of his jobs had been to determine how to efficiently use the factory’s machine tools and at one point management had taken on a contract that he warned them they lacked the capacity to fulfill. They later lost a significant amount of money when they missed deadlines.

The Denver factory did very little manufacturing and was primarily a design and assembly shop, subletting components to various other companies. Middle River had a lot of capability to build things.

Mettee said that they worked for two managers: Bastian “Buzz” Hello and Francis “Fuzz” Furman—Buzz and Fuzz. Fuzz’s claim to fame was that he was the last person to work on Amelia Earhardt’s airplane before it took off on a leg of her flight and disappeared. He appeared in a number of documentaries explaining his theory that she had a navigational problem and missed the tiny island that was her next stop in the Pacific.

The Titan II rocket work expanded Martin’s activities in Middle River. The company built a clean room “cleaner than a hospital,” according to Mettee. He said that Fuzz had to tell his employees “Boys, I’d like you to take a shower more than once a week.”

During a question and answer session Gordon was asked about the pad abort when Gemini 6’s engines shut down on the pad and astronaut Wally Schirra and Tom Stafford sat inside the vehicle rather than eject using the Gemini’s ejection seats. Gordon remembered watching it and thinking “What the hell happened?!” But he thought that Schirra made the right choice by not ejecting. “Most of us would have blown up before we would have ejected,” Gordon said, indicating that the astronauts did not trust the ejection seats. “They were scary things.” The ejection system was also limited in its utility. Gordon remembered seeing a chart that showed the arc of a launch and the few places where they could fire the ejection seats. The majority of the arc was labeled “Ride it out.” He also added that often “the right thing is nothing… do nothing.” At the very least, don’t make a bad situation worse.

A member of the audience asked what had caused the abort and the panelists explained that it was due to a plug that had been left inside a fuel line and had interrupted the flow of fuel. “That was down at the Cape,” Caldwell said. “It wasn’t here!”

Another member of the audience, Westinghouse engineer Ralph Strong, said that he was interviewed on local television during the pad abort and he pointed out that it was not simply the contractor’s fault—a government inspector had also missed the plug. That comment never made it to air, however.