The engine problemby Wayne Eleazer

|

| When the decision was made in the early 1970s to develop the Space Shuttle and end production of all other US launch vehicles, that also constituted a decision to end development of rocket engines other than that required by the shuttle. |

This situation has produced a new urgency in the US space launch industry. New suppliers are seeking entry into the marketplace and well-established companies are presenting new proposals. United Launch Alliance’s announcement that they have chosen Blue Origin to develop an engine to replace the RD-180 confirms how seriously this issue is regarded by one of the major players in the industry. Meanwhile, Aerojet Rocketdyne has proposed a new American-made replacement for the RD-180 engine, while the US Air Force has suggested a larger effort to develop not only new engines but other improved launch vehicle technology as well. All this seemingly has come as a surprise, but at this point it might be instrumental to recall just how we got in this situation.

If you set out to design a launch vehicle, the first thing you would do would be to decide what size payloads it is going to launch and what type of orbits they would require. Once you had done that, the second thing you would do is to decide what the thrust would have to be for the propulsion system, and thus how big the engines would have to be. The engine is the most important factor in designing a rocket, the longest pole in the development tent, the most critical and complex piece of hardware for the booster, and probably the most expensive single component, too.

When the decision was made in the early 1970s to develop the Space Shuttle and end production of all other US launch vehicles, that also constituted a decision to end development of rocket engines other than that required by the shuttle. And the shuttle decision was not just one to end most new rocket engine development; it even ended most engine production as well. The H-1 engines left over from the Saturn I program were considered to be adequate to rebuild into RS-27 engines for the Delta booster for the remainder of that program. Engines from scrapped Atlas E/F ICBMs were rebuilt into MA-5 engines for the Atlas Centaur, and the remaining bits and pieces left from various programs were used to supply the few Air Force Thor boosters that needed new engines. The Titan 34D was supposed to be the last booster developed, so engine production continued for that vehicle for a time. The fact that most engine production stopped supposedly did not matter, since the shuttle was literally the do-all and end-all.

Following the loss of the Space Shuttle Challenger, the shuttle program was cut back drastically, replaced on most missions by resuming production of the older ballistic missile based boosters: Delta, Atlas, and Titan. Resuming production of the Atlas and Delta first stage engines proved to be challenging, as no new ones had been built in so long that some suppliers had gone out of business. In fact, the turbine wheels for the initial new production had to be robbed from the Thor boosters the Air Force had in storage, and two Thor engines were even used in new build Delta boosters. Fortunately, the Japanese were still building Delta boosters and we could purchase key components, such as new turbine wheels, from that source. However, all that effort simply was required just to get back to where we had been before the shuttle decision had been made; we still needed something new. So the Air Force and NASA also started the Advanced Launch System program to replace both the Space Shuttle and the older expendable launch vehicles (ELVs) with newer technology systems, with low cost as a major driving factor in the requirements.

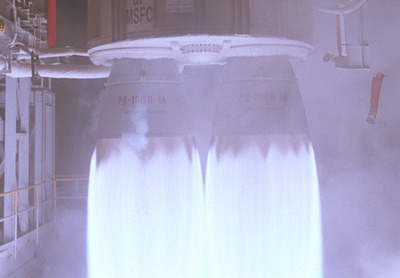

For the ALS, the first step was to design the new engine, and at that point there was not much of anything to work with. The Space Shuttle Main Engine (SSME) was hardly suitable, being complex and expensive, while the rest of the available US designs dated from the 1950s. A clean sheet of paper approach was required, and toward that end a new team, consisting of the leading US manufacturers of liquid rocket engines, was established to design and develop a new engine (teaming of multiple contractors was a very popular idea in the 1980s.) Low engine cost was a key goal, and the ALS engine team studied the way the auto industry designed components in order to reduce the number of parts in critical areas, such as the engine’s injector.

ALS proved to be not too popular with Congress. One reason was that it was a joint Air Force/NASA program and thus required twice as many committees to approve it. The committees in charge of the NASA budget preferred that Air Force pay for the whole thing, and worried that if the Air Force budget was cut that NASA would get stuck with the whole bill. The Defense Department budget committees worried about the same thing, in reverse.

For that matter, the ALS program was not too popular within the Air Force, either. After Congress reduced funding for another Air Force program it liked even less than ALS, the Advanced Tactical Fighter (ATF), the Air Force chose to offer up the ALS funding as an alternative sacrifice.

After ALS was canceled, an essentially identical joint Air Force/ NASA program was created, the National Launch System (NLS). Engine development proceeded in the same basic, slow manner as ALS. And then the Air Force once again offered up its NLS funding to bail out the ATF program; NLS went the way of ALS. Subsequent efforts by the Air Force to develop a new space booster went nowhere for the next few years.

| But by design, EELV was not the program that would focus on truly new technological developments. |

Faced with difficult decisions in this area, the Clinton Administration initiated the Moorman study in late 1993. Tasked with coming up with recommendations for future space launch development, Lt. Gen. Moorman’s team produced ideas that reflected the tough environment for such efforts that existed both in DC in general and the Pentagon in particular. Rather than the protracted clean sheet of paper approach of NLS and ALS, the new ELV would be “evolved.” This approach was thought to be both cheaper and faster than the ALS/NLS approach, and by placing the program solely within the Air Force the number of Congressional hurdles would be reduced.

The new policy was terrific in that it meant we would finally be doing something rather than merely engaging in endless studies and soon-to-be cancelled programs. But the policy also meant there still would be no new ELV rocket engine development. There was neither time nor money available to continue building on the very limited engine foundation started by ALS and NLS. The industry proposals selected by the Air Force for further development for the Evolved Expendable Launch Vehicle (EELV) program reflected these grim realities.

McDonnell Douglas chose to develop a largely new booster, using what you might call an extremely “value-engineered” development of the newest US engine available, the SSME, itself dating from the 1970s. Low cost rather than high performance was the major driver, coupled, of course, with schedule limitations.

Boeing proposed to use the SSME much as it was employed in the Space Shuttle, drop off the engine in a recoverable module during ascent, and retrieve it from the ocean. Various combinations of existing solid rocket motors employed as strap-on stages would enable the design to handle the requirements of heavier payloads.

Alliant Technologies proposed to build an all-solid ELV, based on the new solid strap on motor developed for the Titan IVB. Alliant’s investment in the Titan IVB solid had proved to be disappointing when a combination of serious development problems and the demise of the Soviet Union greatly reduced the numbers of motors needed by the Air Force. Their EELV submission was the company’s attempt to recoup that investment.

And finally, Lockheed Martin, already planning to replace the 1950s-vintage MA-5 engines in the Atlas II booster with an engine based on the RD-170 engine that powered Russia’s Zenit booster, proposed to further develop the Atlas line to produce the Atlas V. The Atlas V would use a rigid first stage structure rather than the stainless steel balloon of the earlier Atlas vehicles, combined with the Russian engine, the RD-180.

For both Delta IV and Atlas V, the companies planned to employ a modified RL10 engine as the upper stage, 1960s vintage hardware that would still be in use. Both companies also planned to use a storable-fuel upper stage like that used on the Delta II for lower performance missions. The Delta IV storable upper stage would still use the ancient AJ-10 engine as upgraded by the Air Force in the 1970’s. The Atlas V’s Agena 2000 upper stage probably would be quite similar. So there was no new engine development for the upper stage, either. The storable-fuel upper stages eventually were abandoned when the two companies realized it would be cheaper to just build more of the RL10-based upper stages than try to save a few bucks with a cheaper and lower performing engine for a few launches.

A SpaceX Falcon 9 lifting off from Cape Canaveral. SpaceX developed its own Merlin engines for the rocket, but those engines are far less powerful that those of interest to the Air Force. (credit: NASA/Charles Babir) |

But by design, EELV was not the program that would focus on truly new technological developments. While EELV proceeded on its own, per the Moorman Study recommendations NASA would focus on building a new reusable launch vehicle (RLV), featuring new propulsion system designs as required, beginning with a subscale version, the X-33. And in reality the engines proposed for the new RLV were not all that new. Rockwell/Northrop and McDonnell Douglas/Boeing both proposed to use the SSME in their X-33 designs. Lockheed Martin planned to base their engine design on the 1960s-vintage J-2 engine used in the Saturn program. Eventually this effort resulted in the Lockheed Martin VentureStar RLV design—which was cancelled years later when studies showed it would not work, or at least not work well enough to meet NASA’s extremely challenging requirements (those largely derived from the shuttle program). Thus, new rocket engine development, never a real priority for the X-33 program, fell by the wayside yet again. EELV was left as the only viable new launch vehicle program.

Even before EELV began, a key question was how many solid rocket motors or liquid engines will be required to achieve the thrust level needed. In studies done in the early 1990s, the answer that came back for liquid-engined vehicles was that either one or two engines would be required, but no more than that.

| The Falcon 1’s Merlin engine was the lowest thrust first stage engine used by a US space booster since the puny propulsion system employed by Vanguard in the 1950’s. |

Building two smaller engines offers the potential for lower development costs but is offset by the requirement that you have to build more engines for each vehicle, driving up production costs. Designs based on one engine may cost more to develop but should have lower costs once the program gets going. It’s a classic trade-off situation. Multiple engines generally do not offer the ability to survive an in-flight engine failure; there’s not usually enough design margin left for that.

So both Delta IV and Atlas V ended up using a single engine in their designs. And although they were radically different engines, their basic designs both dated from previous decades. In fact, Atlas V actually had what amounted to half an engine: the RD-180 essentially is the 1980s-vintage RD-170 sawed in half. Initially neither of these vehicles was going to use solid strap-on motors, but the Air Force had somewhat undersized the basic requirements. Largely commercial requirements eventually drove the addition of solid motors to both the core vehicles.

The EELV program proceeded and ended up producing not just one but two families of new boosters, the Delta IV and Atlas V. Both Boeing and Lockheed Martin indicated intentions to continue with their EELV programs even if they did not win the final production contract, and the Air Force accepted that approach. The new commercial-style approach to launch procurement and the burgeoning commercial launch market seemed to offer the opportunity for the Air Force to take a step back and simply become just another customer, and potentially a minority one at that (in the mid-1990s the majority of launches from Cape Canaveral were for commercial payloads.) NASA initially showed indifference toward EELV, apparently under the theory that their new RLV would emulate the original shuttle concept and replace not only the shuttle but all ELVs. But when VentureStar was proved unviable, NASA fairly quickly seized on Delta IV and Atlas V to launch its missions. After all there was not really anything else available—and once again no need to develop any new rocket engines.

A key feature of the Atlas V initially was that all Air Force missions would fly using American-built RD-180 engines, while the Russian-built RD-180s could be used on commercial missions. The Air Force was uncomfortable with relying on a foreign engine for what might well be its only space booster. As things turned out, the Air Force chose both the Delta IV and the Atlas V for procurement, with the Delta IV initially securing the lion’s share of launches. As a result, plans for an American made RD-180 were put on hold and remain stalled to this day, with reportedly a billion dollars required to achieve US production. Today the Air Force is indeed flying Russian-made engines, not what was planned at the start of the program.

Then along came SpaceX with a totally new design for a liquid-fueled launch vehicle. Unfortunately, the new company believed the oft-repeated assertion that there was a large unmet demand for small payloads and the launch services associated with them. Thus, the Falcon 1’s Merlin engine was the lowest thrust first stage engine used by a US space booster since the puny propulsion system employed by Vanguard in the 1950’s.

When the truth came out that the real market was for medium and heavy launch vehicles, the Falcon 1 was abandoned and the Falcon 9 first stage needed a remarkable 9 engines to meet the mission requirements The Falcon Heavy first stage will need an incredible 27 engines. The Merlin engine used by these boosters has been upgraded to over twice its original thrust level, but at 150,000 pounds-thrust (667,000 newtons) at sea level, it still is only producing thrust equivalent to the earliest engines used by the Thor and Atlas boosters some 58 years ago.

| The rocket engine dilemma the US faces today is not the result of a sudden and unpredicted shift in international relations but is due to both government and industry making the wrong choices, repeatedly, over the course of more than 45 years. |

Meanwhile, other companies had studied the available rocket engines, and finding the available options very lacking and being unwilling to design a new engine from scratch, adopted a foreign engine, the Russian NK-33. The NK-33 is a leftover from the Soviet N-1 human lunar mission launch vehicle, which had a less than stellar launch history. Kistler Aerospace first proposed to use NK-33 engines in their reusable booster. After Kistler went out of business, Orbital Sciences Corp. chose the NK-33 for their Antares booster. Following the engine failure on the fifth Antares launch, Orbital has chosen an engine based on the Russian RD-170, no doubt quite similar to the Atlas V’s RD-180 and also produced in Russia.

For its “new” heavy-lift exploration space booster, NASA is planning to make do with SSME for the first stage combined with new versions of the J-2 for the upper stage. And thus once again the agency has no need to develop a new engine.

To summarize, currently we don’t have one American-made first-stage liquid rocket engine that is being used in the manner envisioned when it was designed, and very few engines designed to either employ the most modern technology or to be produced at low cost.

The rocket engine dilemma the US faces today is not the result of a sudden and unpredicted shift in international relations but is due to both government and industry making the wrong choices, repeatedly, over the course of more than 45 years. Essentially, the country has rather studiously avoided making the effort required for a new engine development. Those decisions seemed logical, reasonable, politically necessary, cheap, or simply inevitable at the time, but ultimately proved to be seriously flawed. Much of our history in this area is not that of constant stunning achievements but rather one of frequent awe-inspiring mistakes followed by mad scrambles to recover. We are once more in that phase today.