How the new SLS engine contract is a step in the wrong directionby Gerald Black

|

| It is ironic that, on the same day that NASA announced this contract to transform the RS-25 from reusable to expendable, Blue Origin accomplished the historic feat of successfully landing a rocket that had flown into space. |

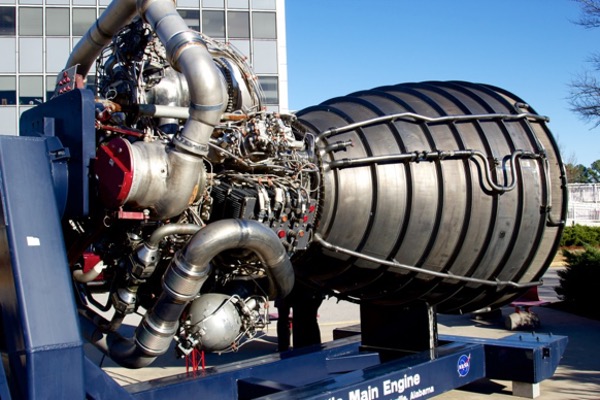

The redesign of the engine will be extensive and will require engine requalification. By taking advantage of advanced manufacturing techniques such as 3-D printing, the new design will have fewer parts and welds, and be cheaper and quicker to manufacture. The engine can also be made lighter and less robust since it needs to fly only once before rusting at the bottom of the ocean.

It is ironic that, on the same day that NASA announced this contract to transform the RS-25 from reusable to expendable, Blue Origin accomplished the historic feat of successfully landing a rocket that had flown into space (see “Blue Origin sticks the landing”, The Space Review, this issue). Blue Origin’s New Shepard rocket and capsule barely passed the 100-kilometer (62-mile) threshold where space begins, topping out at 100.5 kilometers. The rocket and capsule separated as planned, then both landed successfully, the rocket vertically using its main engine.

Blue Origin is not the only company in hot pursuit of reusable rockets. SpaceX has come close to succeeding in two attempts to land the first stage of the Falcon 9 orbital launch vehicle on an ocean platform. In the near future, SpaceX will also attempt to touch down the first stage of the Falcon 9 on land close to the launch site. Sooner or later, SpaceX will succeed and will be nailing these landings, just like Blue Origin did.

Other companies and countries are working on reusable rockets and spacecraft as well. Those working on reusable suborbital vehicles include Virgin Galactic with their SpaceShipTwo, XCOR Aerospace with their Lynx rocketplane, and Masten Space Systems with their vertical takeoff and landing rockets. Those developing reusable orbital launch vehicles include United Launch Alliance with plans to recover the first stage engine compartment of their Vulcan rocket, Europe with plans to recover the first stage engine compartment of the Ariane 6 with their Adeline concept, and Blue Origin with plans to recover the first stage of the as yet unnamed orbital launch vehicle they are developing, using the same approach they did with New Shepard.

| The days of expendable launch vehicles are numbered. |

But by far the most ambitious reusable rocket undertaking is one that SpaceX plans to bring to fruition in the 2020s. SpaceX is developing a launch vehicle of the super heavy lift variety that is reputed to have much higher payload capability than the Space Launch System. The plan is to make this launch vehicle fully reusable, such that not only the first stage but also the second stage would be reused. SpaceX has said that this rocket will be part of a “Mars Colonial Transporter” system that, in addition to the new rocket, would include a spacecraft capable of landing 100 tons of cargo or 100 people on Mars. This rocket does not have an official name yet, but unofficially it’s been called the BFR, for Big Falcon Rocket (or Big F… Rocket).

The days of expendable launch vehicles are numbered. Some naysayers claim that reusable rockets will require too much refurbishment to be economical. However, history suggests that reusable rockets will follow the same pattern as early aircraft and early jet engines. These initially required substantial maintenance and had limited lifetimes, but this changed as designs improved. For example, the first jet engines could only be flown for a few hours before refurbishment was needed, but now a jet engine can remain on the wing for two or three years before needing a major overhaul.

Besides lacking reusability, another problem with the SLS is that the costs are out of control. This is due to several factors. In the NASA Authorization Act of 2010, Congress dictated that existing hardware and infrastructure from the Space Shuttle era be used, thus stifling the development of more efficient systems. This same piece of legislation dictated that the current Space Shuttle contractors and workforce would be used to the maximum extent possible, thus limiting competition that could have brought down the costs. In addition, flat budgeting has led to inefficiencies. Most importantly, the SLS is being developed as a government program utilizing cost-plus contracts where there is no incentive to contain the costs. This contrasts with commercial launch vehicles, where it is imperative to contain the costs.

The SLS program started out with good intentions and the program had wide support at its inception. However, since then, progress in rocket reusability and the emergence of SpaceX has changed the landscape substantially. The time to evaluate whether the SLS program still makes sense is now.

The author believes that the large pot of money spent on the SLS would be better spent on developing a reusable commercial super heavy lift launch vehicle such as SpaceX’s BFR rocket. A competition to develop such a launch vehicle could be conducted following the COTS (Commercial Orbital Transportation Services) model, one that led to the highly successful commercial cargo and commercial crew programs for providing transportation to and from the International Space Station.