CubeSats: faster and cheaper, but are they better?by Jeff Foust

|

| “It was painful,” Johnson said of the work developing Dellingr. “We received components that, out of the box, did not work.” |

Dellingr is also a test case about how well CubeSat-class spacecraft can perform high-quality science. CubeSats have, in recent years, all but taken over the small satellite world, thanks to both the standard dimensions that make it easier to find suitable components and launch opportunities, as well as advancements in technology that enable new and more complex applications. Organizations ranging from elementary schools to venture-backed startups to government agencies have flown CubeSat missions of some kind, and in growing numbers.

But while CubeSats might be cheaper and faster to develop than larger spacecraft, including other smallsats, the NASA Goddard team found that they are not yet better, at least for some applications.

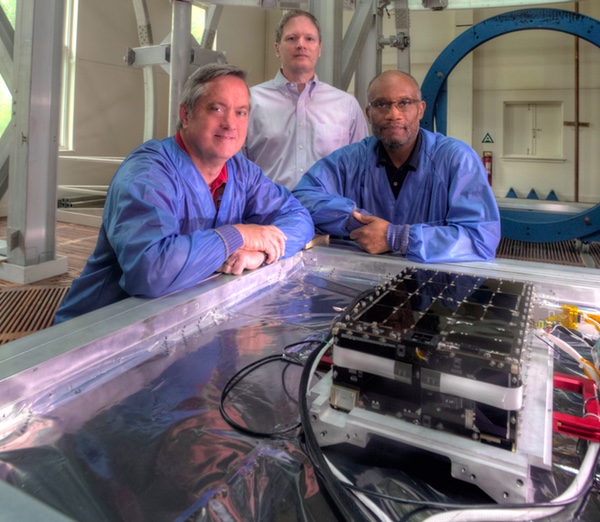

“I often tell people when I talk about our Dellingr development experience is, when we started Dellingr a couple years ago, I had a full head of hair,” said Michael Johnson, chief technologist for Goddard’s Applied Engineering and Technology Directorate, said in an August 6 talk at the 31st annual Conference on Small Satellites at Utah State University. Johnson has little hair today.

“It was painful,” he said of the work developing Dellingr. The project had worked as much as possible to use commercially available components to build the spacecraft, but found many weren’t up to the task. “We received components that, out of the box, did not work. We received components that, when they got to a certain temperature, it would cease working. We received components where the data sheets did not agree with them. We received components with all kinds of issues: fingerprints in places where fingerprints should not be for a spaceflight system.”

Dellingr’s development was prompted by other CubeSat missions NASA personnel had been involved with. Nikolaos Paschalidis, chief technologist of Goddard’s Heliophysics Division, recalled in a NASA statement in early August flying a miniature mass spectrometer on a recent, unnamed CubeSat mission. A communications problem with the spacecraft delayed its commissioning by six months, and while he was able to perform some tests of the instrument, a computer problem abruptly ended the mission.

| “If you’re going to Mars, you can’t do fly/re-try. You have to have confidence that it’s going to work when you get there.” |

“The mission demonstrated the basic functionality of my instrument. However, the experience put a strong emphasis on the need for a robust bus and a complete mission operations scenario,” Paschalidis, who is flying a new version of that instrument on Dellingr, said in the NASA statement.

Such failures have been chalked up to the learning process some see as inherent with CubeSats. Some are built as student projects, where simply getting the satellite into space is a major achievement, regardless of how well it actually works. Others have taken advantage of the rapid development time for CubeSats to quickly iterate their designs, learning from the mistakes of past spacecraft and flying new ones.

That approach, which Johnson called “fly/re-try,” can be useful in some cases, he said. “Fly/re-try works very well, if you can do that,” he said. “However, there are mission concepts where you cannot fly/re-try.”

Those concepts, he said, include some cutting-edge NASA science missions that may have only one opportunity to fly, such as a CubeSat accompanying a larger spacecraft mission to Europa, or a constellation of spacecraft spread out along Earth orbit to monitor space weather conditions.

“There’s some work that we have to do to raise the community from where it is to where we think it needs to be in order to fly some of these mission concepts,” Johnson said. “If you’re going to Mars, you can’t do fly/re-try. You have to have confidence that it’s going to work when you get there.”

NASA already applying the lessons learned from Dellingr to other missions—assuming, of course, Dellingr is successful once deployed from the ISS. A CubeSat mission under development, the Plasma Enhancements in the Thermosphere Satellite, or petitSat, will use a version of the bus developed for Dellingr for its mission to study the Earth’s ionosphere.

A broader approach involves looking for ways to improve the overall reliability of CubeSats. Johnson said that one element of NASA’s new Small Spacecraft Systems Virtual Institute is a Smallsat Reliability Initiative, which seeks to bring together both industry and government experts to discuss how to make CubeSats and other smallsats more reliable.

“The approach is not to break what’s working in the CubeSat area, but to make things better,” he said. That effort included a technical interchange meeting held at Caltech earlier this year.

| Some at the conference, though, wondered if this emphasis on mission confidence or enhanced reliability was missing the point. CubeSats, by their nature, were intended to be quick and easy to build, breaking the paradigms of satellite manufacturing established by large, expensive spacecraft. |

One area of discussion from that initial meeting was the concept of “mission confidence” as applied to CubeSats. Some technology demonstration missions, for example, might be able to get by with low mission confidence, since the mission can be easily reflown if needed. Advanced science or other “critical national” missions might require a very high level of mission confidence.

How to achieve a desired level of mission confidence is something that will be studied as a part of the initiative. Johnson mentioned several tools and concepts, ranging from improved knowledge sharing among CubeSat developers to the use of modeling tools. A second meeting is planned in Washington DC this fall.

Some at the conference, though, wondered if this emphasis on mission confidence or enhanced reliability was missing the point. CubeSats, by their nature, were intended to be quick and easy to build, breaking the paradigms of satellite manufacturing established by large, expensive spacecraft. Any decrease in reliability, they argued, was offset by lower costs, faster development, or the ability to fly multiple spacecraft, mitigating the effect of an individual spacecraft failure.

Planet, which operates more than 160 Dove imaging spacecraft, each a 3U CubeSat, has long championed its “agile aerospace” approach of rapid iteration of its satellites. That means foregoing some of the testing usually done on larger spacecraft.

Rob Zimmerman of Planet, speaking on a panel about mission success and reliability at the conference August 7, said the company does skip some testing on its Dove satellites, like full environmental tests, because the expense is not worth the improvement in reliability such tests might create, particularly when those spacecraft are part of a large constellation. “We’re willing to accept a certain amount of failure in orbit,” he said.

Johnson, who also appeared on the panel, said the goal of his work was not to simply apply traditional mission assurance approaches—including their rigidity and cost—to CubeSats, but instead to take then best of those “heritage processes” and apply them appropriately to CubeSat missions that need greater reliability.

“Speaking from a Goddard perspective, I want to fly a smallsat to Mars,” he said. “I can do that. If I apply traditional Goddard mission assurance practices to that, it will be a whole lot more expensive than it needs to be.”