Why use lunar propellant?by John K. Strickland

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| So why is having a lunar-derived propellant supply in a near-lunar location so favorable? It’s the propellant cost, along with some other good reasons. |

Another problem area is the related but unknown costs of building the lunar mining base, the cislunar base, and the transport system to move the propellant from the lunar surface to the cislunar base, and how much that would add to the cost of lunar propellant. It is very hard to estimate the cost of developing the mining base. Some claim that the cost would be so high as to make the lunar propellant more expensive than propellant brought from the Earth, even though the cost of moving propellant from the Moon is usually quoted at about 15–20 times less that bringing it from the Earth’s surface.

Finally, there is the NASA plan, dormant for a while and now seemingly moving ahead, to create a way to use its obsolete and expendable SLS rocket to support what it still refers to as a lunar “gateway.” This is the project I have referred to in the past as the “Gateway without a Gate.” Very recently, the name and orientation of this project has changed again, to the Lunar Orbital Platform-Gateway, or LOP-G. It may seem as if a station in lunar orbit is more closely associated with actual lunar development, but placing a station in any actual lunar orbit, since it is then in an orbital plane, restricts the number of lunar surface locations that are easily accessible, and some of these so-called “lunar” orbits spend a lot of time far from the Moon.

Since most plans and sources do not mention refueling and logistics facilities as integral and initial parts of this project, such a “gateway” would neither be able to support a lunar base nor support dispensing lunar propellant produced by such a base, and are unlikely to be added later. A NASA request for information (RFI) in late 2017 covered many aspects of gateway science, but not a single transport issue. Most people would agree that an actual gateway provides a pathway to some physical location. So where is the physical path for this gateway? Where does it lead from and what does it lead to? In spite of the acronym, the planners have lopped off the critical gateway (transport-related) features—if they were ever there to begin with.

Some people fear that this project would eat up any and all funds for an actual lunar mining base and thus are now insisting that any lunar base be supported only from low Earth orbit, which is less efficient. If the platform is supported by the SLS, it would eat up even more funds, leaving little for any other human space projects, and could delay the establishment of an actual lunar base by a decade. With time, bureaucrats could decide that it is too dangerous to have propellant depots docked at the “gateway.” When the powers that be finally realize that crews stationed beyond LEO actually do need a significant amount of shielding mass to protect them from cosmic radiation, the whole project could be thrown into redesign disarray and last another decade before even being launched.

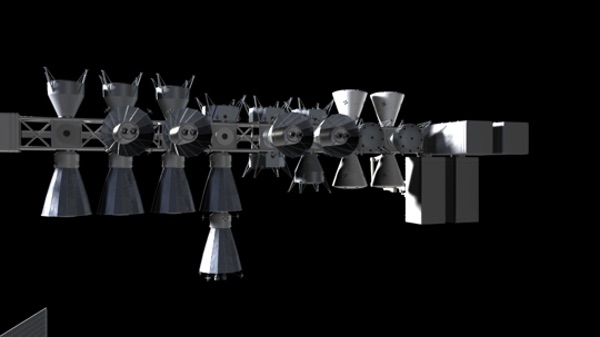

Obviously, a vehicle about to depart for Mars will not want to land on the Moon to get its propellant. Even getting into lunar orbit from a cislunar location would waste fuel. Thus, most experts believe that a location like Earth-Moon L1 or L2 is the best place to accumulate a large store of propellant, since it is always in the same position relative to the Moon and Earth, and thus is not subject to orbital plane limitations. Since vehicles ready for either departures to Mars or to cyclers going to Mars would need to be positioned at locations other than L1 (but at about the same distance from Earth), the main propellant depot would probably be at L1, with temporary depots positioned at other locations during Mars transit windows every 26 months.

So why is having a lunar-derived propellant supply in a near-lunar location so favorable? It’s the propellant cost, along with some other good reasons. If you want to go to any location outside the Earth-Moon system, whether it is Mars or an asteroid, a departure location high above Earth is best since that allows a very efficient Oberth maneuver, which uses a departure burn at L1 and another during a close pass of the Earth. This saves more than half of the departure propellant compared to departure from LEO, and for Mars missions, this means the Mars transit propellant weighs less than the mission’s dry mass. (If you are not using any lunar propellant, the advantage of the high departure point is much less.) From L1, lunar propellant can be delivered to LEO for only about 0.85 kilometers per second of velocity change, and even directly from the lunar surface for about 2.74 kilometers per second, making delivery much cheaper there than Earth propellant, which needs about 9.5 kilometers per second for delivery.

| You need a huge amount of propellant to move the Mars transit propellant from Earth, but only a small amount to move it from the Moon. |

Having a base in a location like L1 makes initial support of a new lunar base much easier, since it is possible to reach L1 from anywhere on the Moon’s surface (or the reverse) in about 12 hours without worrying about the orbital planes. It also breaks the trip from LEO to the lunar surface into two smaller steps in terms of velocity change, thus decreasing the dry mass and fuel mass fraction of each vehicle, and allowing each one to carry relatively more cargo or propellant. This also improves the safety factor, since smaller rocket engines can be used, and they do not fire as long.

The big factor, however, is still the vast cost difference in moving the fuel to L1. The difference is primarily caused by the fact that you need a huge amount of propellant to move the Mars transit propellant from Earth, but only a small amount to move it from the Moon. Let us assume that we have vehicles ready for a Mars mission, either three large 85–100 ton dry mass vehicles, similar in size to the SpaceX BFS stage, able to carry a small crew plus a lot of cargo, or a set of ten smaller 30-ton-range dry mass vehicles, some for crew and cargo and some just for cargo. Assume that both fleets have about 4,000 tons of dry mass and need about 2,100 tons of propellant at L1 to depart via an Oberth maneuver. To show the huge numeric difference in cost between Earth-based and lunar based propellant at L1, we do need to do some simple calculations.

Note that in these calculations, I distinguish between the mass of the rocket propellant needed to move the Mars transit propellant to L1, and the mass of the Mars transit propellant (the payload) itself. To avoid confusion, I will refer to the transit propellant as the transit propellant payload, the surface to LEO propellant (a) carrying the transit payload to LEO, and the surface to LEO propellant (b) carrying up the LEO to L1 propellant needed in LEO to move the transit payload from LEO to L1. On the opposite side of the scale, I will refer to fuel for the cislunar tanker which carries the lunar-derived transit propellant payload as the lunar to L1 propellant. The multiple kinds of propellant uses may be confusing, but these distinctions are crucial to understanding the huge cost difference. All named transport propellant loads include the return to base propellant, as all vehicles are reusable.

Let’s assume you have moved your Mars expedition fleet dry mass (less the transit and bootstrapping propellant) to either a position at L1 or into a high orbit that is at a similar distance from Earth as L1 is, ready for its Oberth-style Mars departure maneuver. The transit propellant payload will need to include all of the propellant (a minimum of 400 tons) needed for bootstrapping the initial landings on Mars before the surface propellant plant there can be set up. During transit, this propellant can be kept in vehicles with cryo-coolers or in one or more propellant depots equipped with cryo-coolers. All in-space propellant discussed here is cryogenic liquid oxygen (LOX)-liquid hydrogen with an assumed specific impulse (Isp) of 460 seconds. All loads of the transit and bootstrap propellant to L1 are 150 tons, and thus a single expedition needs 14 such loads.

What is the amount of propellant mass to move the needed approximately 2,100 tons of transit propellant to the fleet at L1 or a similarly high orbit? Propellant created on Earth for use by this fleet would be moved to L1 in two steps, supported by multiple launches from the surface. If the BFR tanker version is used, 150 tons at a time can be delivered by one BFR tanker to a LEO logistics base. Reaching LEO takes about 9.5 kilometers per second of velocity change. There it is transferred to a small reusable tanker with sunshade and cryocoolers, which will take it from LEO to L1. This takes another 3.77 kilometers per second, for a total delta-V of about 13.27 kilometers per second. To provide propellant for the small tanker, almost two more BFR tanker loads of LEO to L1 propellant need to be delivered to the LEO base per 150-ton load of transit propellant payload. All of the BFR tankers would reenter and land back on Earth. The small tanker would offload the cryogenic propellant to shaded and refrigerated depots at the L1 base, and then, minus its payload, would drop back toward Earth, where it would use a single pass aero-capture maneuver to get into LEO again for a tiny amount of fuel.

For transport of Earth-based propellant, I will use current numbers for the SpaceX BFR (tanker version), as the launcher, which uses LOX-methane propellant. At 4,400 tons liftoff mass, we can subtract the dry mass to get the total propellant mass. The payload (wet or dry) is 150 tons, the upper stage is 85 tons, and the first stage is probably at about 125 tons, giving a total dry mass of 360 tons and thus a nominal surface to LEO propellant (a) mass of 4,040 tons, with almost 1,000 tons of propellant in the second stage. The propellant to payload ratio for this description of a BFR would be 4,040/150 or 26.93: 27 tons of propellant is needed for every ton delivered to an LEO base. The payload mass ratio is an impressive 0.0341. The structural mass ratio for the second stage is also an impressively low 6.9 percent (85 tons/1,225 tons). These numbers will probably change some as the extremely efficient BFR designs are refined further by SpaceX.

| If future lunar entrepreneurs can beat that price, and if lunar water ice does exist in minable quantities, the lunar fuel production enterprise seems assured. |

We will assume that, at LEO, the 150-ton transit propellant payload is then transferred to the smaller tanker of the same cargo capacity but with smaller engines which use only LOX-hydrogen. Note that the launches from the Earth’s surface need to supply the small cislunar tanker with both the LOX-hydrogen LEO to L1 propellant plus the LOX-Hydrogen transit propellant payload itself. The LEO to L1 tanker is already in orbit. Assuming that the smaller tanker is about 25 tons and has its own cryo-coolers and sunshade, its structure and payload would weigh 175 tons. The delta-V from LEO to L1 is 3.77 kilometers per second, and about 1.0 kilometers per second for the return trip where aerocapture and a small orbit trim is all that is needed. This means the small tanker needs to carry only 7 tons of descent propellant with it to L1, with a margin. This then means the mass that reaches L 1 must be 182 tons, so the ascent (LEO to L1) propellant mass, also with a margin, is 250 tons. The total mass departing LEO for L1 is now 432 tons. Note that the structural dry mass for this small tanker at departure from LEO is 5.8 percent.

However, the 257 tons of LEO to L1 propellant needed to move the single load of transit propellant payload propellant to L1 and get the empty tanker back to LEO also needs to be moved up to LEO first, and requires the use of 6,921 tons of LOX-methane surface to LEO propellant (b) on more than one ride to LEO via the BFR. It costs about $200,000 to launch a Falcon 9 with about 500 tons of fuel (LOX and RP1) on board, thus that fuel combination costs about $400 dollars per ton. LOX-methane might cost about the same. So, in order to get each 150-ton batch of Mars departure propellant to L1 from Earth, it takes the following components:

Propellant masses for delivery of 1 & 14 loads of 150 tons of LOX-hydrogen to L1

| Payload | payl mass | prop mass | vehicle | from | to | propel. cost |

|---|---|---|---|---|---|---|

| Mars Transit prop (payload) | 150 | 4,040 | 1 BFR tanker | Earth | LEO | $1,616,000 |

| LEO to L1 tanker propellant | 257 | 6,921 | 2 BFR tankers | Earth | LEO | $2,768,400 |

| Mars transit prop (payload) | 150 | 257 | 1 cisln tanker | LEO | L1 | 102,800 |

| Total propellant mass | - | 11,218 | both | Earth | L1 | $4,487,200 |

| (Multiply by 14 BFR and tanker loads to L1) | ||||||

| Total propellant mass to L1 | 2100 | 157,052 | both | Earth | L1 | $62,800,000 |

This is a 74.79-to-1 ratio of propellant to payload delivered to L1 (11,218/150). The transport propellant for one load of Earth propellant thus costs $4.49 million at $400 per ton so that just one ton of Earth propellant delivered to L1 would be worth about $30,000, based only on delivery propellant costs. The total propellant mass needed to deliver 2,100 tons, or 14 BFR loads, of transit propellant payload to L1 is 157,052 tons and costs $63 million, making the propellant cost a major part of a single Mars mission cost when conducted with reusable vehicles. If there were 100 civilian passengers on the trip, the fuel would cost each person $628,000.

Now let’s see how much lunar to L1 propellant is needed to get the transit propellant payload propellant from the Moon to L1. In this case, we are using a lunar to L1 tanker with LOX-hydrogen fuel. It takes 2.6 kilometers per second to go from the lunar surface to L1 and the same to return, but fuel use on return is minimal since there is no payload. I assume that this tanker is 30 tons, since it needs landing legs and it leaves the lunar surface with the same 150 tons of cargo, for a dry and payload mass of 180 tons. The empty 30-ton tanker will need just 25 tons of fuel (with a margin) to return to and land at its lunar base without its payload, so the structural mass, payload, and return fuel mass is 205 tons. The vehicle leaving the lunar base with its payload of fuel needs 170 tons of propellant, with a “wet” mass of 375 tons, so for the whole round trip (where the payload is left at L1), the fuel needed is just 195 tons of propellant.

Reusable Lunar surface to L1 & return tanker masses

| Trip Component | 1 load mass | mass fraction | mass for 14 loads |

|---|---|---|---|

| Dry structural mass | 0 tons | 0.08 | 420 |

| Transit propellant payload | 150 tons | 0.40 | 210 |

| subtotal | 180 | 0.48 | 2520 |

| return to base propellant | 25 tons | 0.07 | 350 |

| subtotal | 205 | 2870 | |

| surface to L1 propellant | 170 tons | 0.45 | 2380 |

| total mass at liftoff | 375 | 1.00 | 250 |

| total round trip propellant | 195 tons | 0.52 | 2730 |

Notice that this means for a well-designed light tanker ferry, for every 1.0 tons of payload propellant it only takes 1.3 tons of fuel propellant to move the payload from the surface base to L1. At lunar takeoff, this tanker would mass 375 tons, but since it is taking off in lunar gravity, it would effectively weigh only about 62 tons. The composite propellant tanks, similar to what will be used for the BFR, would probably mass only 20 tons, leaving 2 tons for the engines, 2 tons for the landing legs, and 6 tons for the rest of the structure, including the cryo-coolers, sunshade and power system. This provides a structural mass fraction of 8.0 percent.

| Plans for the NASA cislunar base must accept that large propellant depots can be attached to it. |

At this point, we do not know the actual cost of the lunar propellants as delivered to the tanker at the lunar base, including the vehicle development costs, but finally we can compare the relative mass of the delivery propellants. Assuming that we have not underestimated the tanker mass, the delivery propellant mass from Earth to LEO to L1 is 57.5 times more (74.8/1.3) than the delivery propellant mass from the Moon to L1 for the same 1 ton of propellant as payload. (Note that this mass difference is about three to four times larger than the typical cost difference of 15–20.) Cost of lunar fuel would include fuel production costs, transport propellant costs, and vehicle operation costs. The wear and tear on lunar-to-L1 vehicles is much less, since no vehicles need to take off from the Earth or re-enter the Earth’s atmosphere. Even the cislunar tanker must undergo an aerocapture to return to LEO from L1, while the lunar-to-L1 tanker would encounter only the stresses of thrust and landings. In addition, propellant at L1 is at least twice as valuable as propellant in LEO, due to the gravitational potential and additional velocity from an Oberth maneuver performed starting at L1.

So if the lunar propellant cost proportionally as much as the delivered Earth propellant before the lunar propellant is delivered to L1, it might cost about $23,012 per ton (57.5 times $400), or ($29,915/1.3) on the lunar surface. If future lunar entrepreneurs can beat that price, and if lunar water ice does exist in minable quantities, the lunar fuel production enterprise seems assured. Sales of large amounts of propellant for Mars expeditions would assure a robust human presence on the Moon. However, to assure that the logistics capability of any cislunar or L1 base will exist, the propellant depot and cargo handling capabilities must be a part of the design of the base from the beginning. Plans for the NASA cislunar base must accept that large propellant depots can be attached to it.

We are getting significant indications of international interest in a lunar base. At the same time, NASA says that there may not be enough room on the LOP-G station to accommodate international science participation. Why does the cislunar base have to be so small if there is support for it? The solution to this problem is a package deal agreement where there is a combined cislunar, lunar, and fully reusable transport development effort taking place simultaneously, with the international partners providing some of the transport and lunar surface infrastructure, with heavy reliance on commercial launches. Development would take place so that the first human landings at a lunar base site would take place within a year of the cislunar base completion. Without such a “package deal,” the NASA cislunar base would probably become the “gateway with no gate” or a “space station junior” copy with very limited utility, as many of us have feared.