The robotic space stationby Gordon Roesler

|

| It turns out that such an uncrewed, robotically-enabled space station would have tremendous utility. |

But, more fundamentally, it is a destination: a node where multiple space vehicles arrive and depart, delivering or retrieving cargo or humans. It differs from most satellites in being highly adaptable, having a configuration that is not static. A space station is a multi-mission, multi-purpose entity, providing electrical power, orbit maintenance, attitude control, protection from the space environment, communications, and other services to its users.

The need to support human life and safety has dominated the system requirements and operational constraints of current and past space stations. However, can a space station be useful if it has no provisions for human presence?

It turns out that such an uncrewed, robotically-enabled space station would have tremendous utility. It could enable the development of new capabilities for scientific and engineering applications, save money in the hosting of experiments and instruments, prove out technologies that will be required later for human planetary exploration, and support revenue-producing applications for private sector participants.

Robotic technology advances

The time is right to consider building a robotic space station. The use of robots on Earth is growing at an incredible rate. New scientific and commercial applications for robots in Earth orbit have been identified, creating a demand for new robotic systems and behaviors. The first commercial orbiting robot is expected to be launched in 2021. Robotic technologies needed to prepare the way for human exploration could be matured there. And since the ISS is approaching the end of its life, a robotic space station could provide continuity for many valuable services and experiments currently performed on ISS.

On Earth, the use of industrial robots is growing exponentially, with almost 300,000 sold in 2016,1 and over 380,000 in 2017.2 These robots are used where tasks are “dull, dirty, or dangerous,” and where they increase productivity of the manufacturer. The largest purchasers of robots are the automotive and semiconductor industries, but they are finding uses across a wide range of sectors, including construction, energy, food processing, and agriculture.

| There is growing interest in another space robotic capability: assembly. |

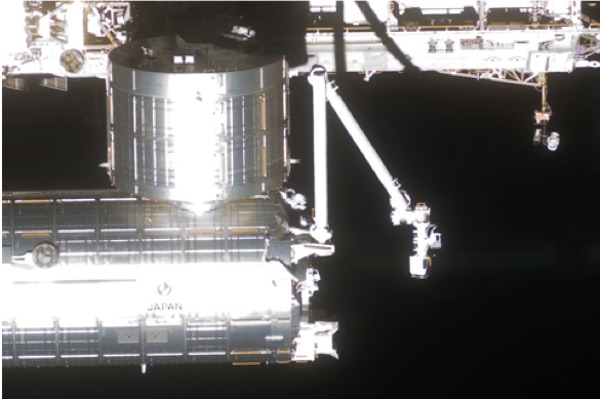

Space is a perfect place for robots, as numerous planetary probes have shown. Robots that remain in orbit have different requirements than either terrestrial or planetary robots, so it is not simply a matter of buying existing robots and launching them. But numerous robotic systems have performed successfully in Earth orbit, including the Space Station Robotic Manipulator System or “Canadarm2,” the Japanese ETS-VII experiment, the Orbital Express demonstration mission by the Defense Advanced Projects Agency (DARPA), the ROKVISS experiment of the German Aerospace Center (DLR), and the Japan Experiment Module Remote Manipulator System or JEMRMS.

The JEMRMS arm developed by JAXA onboard ISS. (credit: JAXA/NASA) |

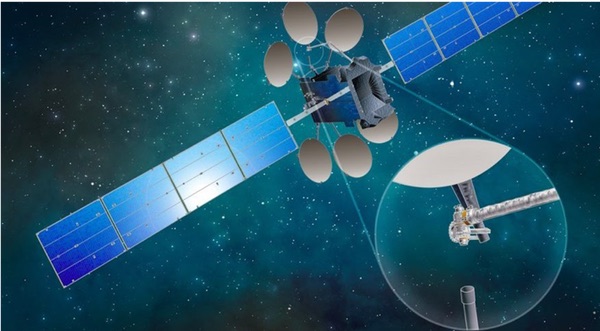

Commercial robotic systems in Earth orbit will appear in the near future. One of the first will be the Robotic Servicing of Geosynchronous Satellites (RSGS) servicer, a joint project of DARPA and SSL, a leading manufacturer of GEO satellites. Working toward a launch date of 2021, RSGS is designed to fulfil several specific capabilities:

- Automated docking to a customer spacecraft’s launch adapter

- Close inspection of external customer features

- Mechanical manipulation, for missions such as correcting deployment anomalies

- Attachment of modules with new capabilities to the exterior of customer satellites

- Refueling through the customer satellite’s propellant fill and drain valves

- Repositioning a customer satellite using the servicer’s thrusters

The robotic system of RSGS and the satellite carrying it are designed for very long lifetimes, to be able to travel to and service multiple customers. These servicing missions will provide extensive data to benefit future space robotic systems, and could inform the architecture for a robotic space station.

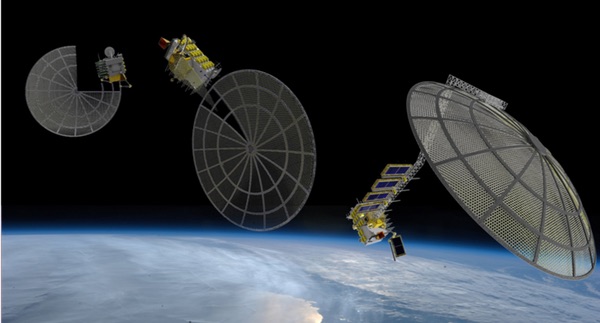

There is growing interest in another space robotic capability: assembly. Communications satellites in GEO can serve more customers with larger reflectors, but current reflector sizes are limited by accommodation in launch vehicle fairings. Robotic installation of larger reflectors would provide satellite operators with additional revenue. Development of such a capability is in progress in SSL’s Dragonfly project, supported by NASA’s Tipping Point program. In-space manufacture of even larger reflectors is being explored in Made In Space’s Archinaut effort, also supported under Tipping Point.

Some new concepts for space telescopes are also candidates for robotic assembly. While all current orbiting telescopes have been placed in orbit via single launches and deployed as self-contained units, some new designs are so large that monolithic launch and deployment are impractical. NASA has commissioned a study of the benefits and methods of using modular assembly to build large astrophysics instruments. A recent NASA report3 describes how robotic assembly could provide risk and cost benefits to a future exoplanet characterization instrument, and suggests using RSGS to test assembly techniques.

Another robotically enabled concept is also being studied: building satellites on orbit rather than on Earth. From a recent report4 by the Institute for Defense Analyses’ Science and Technology Policy Institute on the subject:

Researchers and experts for more than 10 years have proposed replacing at least some aspects of this terrestrial [assembly] architecture with an approach where spacecraft, satellites, and other objects are partially or wholly assembled or manufactured in space. This set of activities is jointly referred to as on-orbit manufacturing and assembly. While developments are still at low readiness levels, in recent years, several advances have been made. On-orbit manufacturing has recently been demonstrated on the International Space Station (ISS) through additive manufacturing, sometimes referred to as three-dimensional (3D) printing, of small components, such as plastic tools. Many of the technologies and processes required for on-orbit assembly are being developed actively in the areas of on-orbit inspection and on-orbit servicing of spacecraft.

A related concept is the construction of platforms to host scientific, commercial, and even military payloads. The basic idea is that of a structure with connectors to provide power and communications for multiple payloads delivered to the structure over time. By providing attitude control, orbit maintenance, and utilities, the use of a persistent platform increases flexibility and decreases costs. From the same IDA STPI report:5

In Earth science, on-orbit assembly could reduce the number of satellite launches for weather and climate observations through the creation of a persistent platform assembled in space. One illustration is the ability to use the persistent platform to replace the A-Train series of six satellites that pass over the same spot on the Earth within a few minutes of each other collecting a variety of measurements. Sensors could be added to the persistent platform on an ongoing basis, enabling faster refresh than is currently feasible. Just as importantly, assembly of multiple payloads (as well as refresh) onto one persistent platform could require fewer launches. For example, if it were possible to deploy six payloads onto the persistent platform using three launches, the potential launch savings could be several hundred million dollars.

| Given all these compelling trends, what should the goals of a robotic space station be? It should help to transform space operations by bringing more robots to space and doing more with them. |

The savings realized from persistent space platforms would not be limited to reducing the number of launches. Today, placing a sensor payload into orbit means buying a complete satellite bus for each payload that provides propulsion, attitude control, electrical power, and so on. This also increases the cost of integration and testing, lengthening the program schedule, and thus making many valuable Earth-sensing missions cost-prohibitive. The use of a persistent platform to host scientific payloads would eliminate these costs, providing an overall savings if a sufficient number of payloads is launched to leverage the platform cost.

Artist’s concept of SSL’s Dragonfly arm installing an RF reflector on a communications satellite. (credit: SSL)

|

The big picture

Given all these compelling trends, what should the goals of a robotic space station be? It should help to transform space operations by bringing more robots to space and doing more with them. Being adaptable and designed for change, it should meet the needs of as many users as possible—commercial, scientific, and government—in as affordable a manner as possible. It should capitalize on the burgeoning terrestrial robotics technology to catalyze the expansion of space robotics-enabled capabilities. It should leverage the expanding field of affordable launch offerings. It should buy down risks for future exploration missions. It should focus on tests that can’t be done on Earth. It should replace as many of the hosting capabilities of ISS as possible, without a pressurized volume or human life support equipment. It could also host devices and techniques that are unsafe for ISS. It should be placed in an orbit that makes sense in light of the economics of launch and orbit maintenance. And it should be developed from the beginning as a public-private partnership, to attract investment capital which will fuel the development of the space economy.

Future plans for space technology and development must consider the approaching end of life of the ISS. NASA has solicited ideas for low Earth orbit commercialization,6 including commercialization of ISS itself. Without ISS, a gap would occur in some key LEO capabilities, such as the deployment of small satellites, the hosting of scientific and commercial experiments, and the existence of a flexible platform where modularized instruments are mounted in the vacuum of space and provided with power.

Today, there is a flurry of private development of small, relatively inexpensive launch vehicles. The proliferation of small satellite concepts represents a large potential market for these rockets, should they prove successful. Because of safety considerations, they are not used to deliver cargo or experiments to ISS, but these vehicles represent a tremendous opportunity if they can be integrated into a robotic space station’s logistics. Low-cost rockets and payloads making deliveries could be practical with some supporting technology. Overall, the new class of launch vehicles promises a more robust space logistics infrastructure, if incorporated in future system concepts.

Designing an RSS

These principles translate into some system requirements for the robotic space station, or RSS. First, it must be built robotically. In-space construction techniques using robots are not as mature as those involving astronauts. However, developments at various companies and laboratories are yielding rapid progress. The RSS could certainly be based around robotically constructed trusses, using techniques being developed by Northrop Grumman and its partners in the Commercial Infrastructure for Robotic Assembly and Services (CIRAS) project. The various supporting systems, including electrical power, attitude determination and control, propulsion, and communications, would be integrated onto the truss assembly. Harnessing—connecting the systems electrically—would be a major task for the robotic construction system.

Deliveries to the RSS make it a space station rather than a standalone experiment. Low-cost launch vehicles could greatly reduce operations costs, and would be enabled by an external robotic system, a function of the SSRMS on ISS. Keeping delivered payloads as simple as possible will also help to control costs. The ISS visiting vehicles are equipped with highly capable systems for rendezvous with ISS and conducting proximity maneuvers, together referred to as RPO. The SSRMS grapples the visiting vehicles and pulls them into the berthing station.

However, if low-cost launch vehicles are to be used for deliveries to RSS, payloads should be kept simple, and not require a full RPO sensor and control suite. Instead, an orbital retrieval vehicle could be deployed to operate in support of the RSS. The ORV, equipped with robotic arms and a full RPO suite, could provide the “last mile” service, grappling payloads at a safe distance and bringing them into proximity with the RSS, where an SSRMS-like external robotic arm could retrieve them. Because payloads are lighter, so could the external arm be as well.

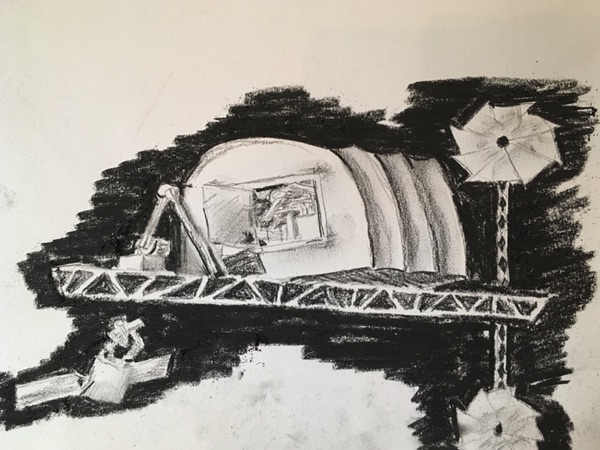

A conceptual robotic space station with orbital retrieval vehicle. (Drawing by the author.) |

Although the RSS will have no pressurized volume, it should provide an enclosed space for protection of equipment from micrometeorites and for thermal considerations. Such a space does not need to be delivered in fully assembled form, as were pressurized ISS volumes; it could be built robotically from interlocking tiles. Lightweight Whipple shields7 could be robotically erected to surround the enclosed volume and other critical components, such as the attitude control system. Within the enclosed space, scientific experiments, handling robots, assembly jigs, and other functional components could be housed. The figure above is a cartoon of a rudimentary RSS with shielded enclosed volume, ORV, and external retrieval arm.

| In-space assembly and manufacture of large reflectors for communications satellites may have significant benefits for the GEO communications satellite market. |

One attractive orbit for an RSS could be sun-synchronous, providing a hosting platform for future instruments that are successors to the A-Train. This orbit reduces the upmass compared to a lower inclination (e.g. over KSC) but could greatly reduce costs for Earth-observing instrument programs. For hosting such instruments, considerable work has been done on interface development by the Earth Science System Pathfinder program, part of NASA’s Earth Sciences Directorate. In designing RSS, both the ESSP’s Hosted Payload Interface Guide and Best Practices document may represent sufficient standards for the instrument developer. A standard interface for mounting and powering the instruments will still be required.

In fact, interfaces will be a critical aspect of RSS design throughout its life. Construction of the RSS would probably begin with the launch of a construction module, along the lines of CIRAS, to build the central truss to which all other parts interface. Since all handling and assembly will be performed robotically, each delivered component, and each scientific module, must include interfaces to the relevant onboard robotic systems. Some of the robots themselves may require interfaces for walking, as does the Dragonfly arm. It may be desirable for the ORV to have a docking station to reduce its propellant consumption, which will require an additional type of interface. External interfaces should allow for RSS expansion as additional commercial tests, demonstrations, experiments, and commercial processes are developed. A Payload Accommodations Handbook, similar to the one for ISS, should be a high priority.

Since a significant fraction of astronaut time on ISS is devoted to maintenance and repair, a capability for RSS robotic maintenance and repair must be carefully incorporated into its design. Human visits to RSS should not be ruled out a priori, but the cost and safety implications must be considered. There are few examples of self-repairing robots today, although some research is being performed.8 Strategies for RSS maintenance and repair could include:

- Redundancy: avoiding single-point failures of the key robots that keep the station operating (e.g. have two large external arms, and multiple rails for internal handling robots);

- Replaceability: where repair is not feasible, replacement of some components (storing the failed ones in a trash bin) should be a design feature; and

- Research: developing capabilities for robotic repair of robots, perhaps including the use of on-orbit fabrication.

Commercial use of an RSS

Is there the potential for revenue-producing activities hosted on an RSS to attract private investment? Historically, while there has been great interest in including commercial activities on the ISS. It was enabled by statute9 as far back as the year 2000, the ability of ISS to attract commercial projects has been limited. On the other hand, some emerging applications have significant potential for new revenue. Lessons learned from commercial operations on ISS should be incorporated into RSS planning if they contribute to greater utilization.

In-space assembly and manufacture of large reflectors for communications satellites may have significant benefits for the GEO communications satellite market. NASA has sponsored a project to explore one potential technology. The RSS could act as a testbed platform for further developments. There may be synergies with assembly robots and techniques to be used for in-space telescope assembly, which could also be tested on RSS.

Other recent concepts have the potential for significant positive returns as well. NASA has recently sponsored a project to produce very high quality optical fibers aboard ISS. Terrestrial telecommunications require ever-increasing amounts of fiber optics for data transmission, and higher quality fibers means lower costs for that industry. Optical fibers are also used in various types of lasers, and fiber quality can have significant effects on their performance.10 Should the initial experiments prove promising, RSS could be used not just for experiments, but as the actual production platform. A fiber production module could be hosted inside or outside the enclosed RSS volume, depending upon requirements.

Producing materials and products in space for terrestrial use requires means of deorbiting them. Such a development would have to be implemented in parallel with developing the manufacturing capability itself. Today, downmass from ISS is returned almost exclusively in SpaceX’s Dragon capsules. While Dragon could potentially be used for RSS resupply, smaller systems for returning cargo might also be considered, such as drag or ballute-based deorbit devices.11

Recently, the ability of ISS to deploy small satellites has resulted in significant commercial usage. The RSS should definitely provide this capability. Safety considerations on ISS have precluded using energetic propellants on satellites to be deployed. Given the absence of humans on an RSS, this restriction might be relaxed to some degree. The layout of the RSS could be arranged to minimize potential damage to other RSS systems in the event of a propulsion system energetic event.

| One of the starting points of an RSS effort should be to establish it as a public-private partnership. This would reduce the impact of the RSS cost on the government’s budget, and results in greater flexibility for design and operation of the station. |

As mentioned earlier, there is significant interest in on-orbit assembly of satellites themselves. Numerous advantages and cost benefits of this capability can be imagined: design for mission rather than for launch, reduced integration and testing costs, and leveraging of smaller launch vehicles. Modularization and standardization will be required to make this approach routine,12 but the economics are extremely attractive. Some modular satellite concepts have achieved a high level of maturity. California-based NovaWurks has developed the HISat, a modular satellite building block that has already been flight tested. The German Aerospace Center (DLR) has supported the development of “intelligent Building Blocks for On-Orbit Satellite Servicing and Assembly” or iBOSS. The iBOSS interfaces could also be useful for attaching scientific payloads to an RSS.

An associated space tug is probably essential to make in-orbit satellite assembly practical, as the assembled satellites must be delivered to orbits other than the RSS orbit. The tug may have requirements that are very different from the orbital retrieval vehicle that supports RSS. The ORV must make frequent, small-ΔV trips to retrieve small payloads for RSS logistical support and hosted experiments. The delivery tug will make large-ΔV excursions, as plane changes and altitude changes will likely be required. Thus, the propulsion systems of the two vehicles have different requirements. Both should be designed to be refuelable.

One of the starting points of an RSS effort should be to establish it as a public-private partnership. This would reduce the impact of the RSS cost on the government’s budget, and results in greater flexibility for design and operation of the station. Such partnerships are often broached before the needs of the private sector are understood and accepted. The overarching need is for the project to result in revenues that allow a recovery of the private sector investment. There are other details, such as ownership of intellectual property and of the RSS itself, that must also be worked out. But humanity’s expansion into the solar system will succeed in the long run only if it makes economic sense, and RSS is as good a place as any to start putting that principle into practice.

Government technologies and support

There are multiple motivations for the US government and partner nations to develop an RSS. Some have already been mentioned: to accelerate the introduction of robotics into Earth orbit, thereby stimulating the growth of the space economy; to test robots that will eventually prepare the way for human exploration; and to validate robotic assembly concepts for such systems as orbiting astrophysical observatories.

In addition, RSS can provide many capabilities presently provided by ISS, such as:

- Deployment of small LEO satellites

- Performing scientific experiments within the protected volume

- Hosting Earth-observing instruments and other external payloads

- Experimenting with on-orbit manufacturing techniques, which could benefit commercial, civil, or national security applications

| Flying a robotic space station would truly represent the dawn of the robotic space age. |

In the latter case, NASA is investing in the FabLab concept to validate multi-material in-space manufacturing concepts. Long-duration human exploration missions will require the ability to make repairs, and cannot bring a complete stock of repair parts along. Maintaining a FabLab-like capability on RSS can add operational experience and lessons learned for space systems for the benefit of all space system developers.

Current technologies that could be used or modified for construction and operation of an RSS have been primarily developed under government sponsorship. Some of the most significant that are relevant to RSS development are:

- Truss construction equipment and techniques, such as those of the CIRAS program

- Large external robotic arm for payload retrieval and other functions, such as the Next Generation Large Canadarm

- Smaller arms for payload manipulation and assembly tasks, such as the Dragonfly arm.

- Robotic arms for an orbital retrieval vehicle and space tug, such as the FREND arm developed by MDA-US Systems for the RSGS and Restore-L programs

- Software for automated grappling operations of robotic arms, such as that under development at the US Naval Research Laboratory for the RSGS program.

In the long run, it is highly desirable to migrate these technologies to industry, so that commercial robotic capabilities flourish—another goal for an RSS public-private partnership.

Conclusion

The design, development, and deployment of a robotic space station would be a major undertaking, although of lower cost and less demanding than for crewed space stations of equivalent capability. Such a robotic station could perform a myriad of valuable functions. Most importantly, it would be the most significant vehicle for pushing robotics into space. Beyond those missions envisioned for the RSS itself, the very flexibility of robotics will lead to missions, capabilities and businesses that have not yet been imagined. Human expansion into the solar system will be more robust if preceded by capable and tested robotic systems, to prepare habitats, process resources, and provide support for crewed missions. Flying a robotic space station would truly represent the dawn of the robotic space age.

Acknowledgements

The author greatly appreciates the contributions of Brook Sullivan of Sullivan Analytical and Technical Services and Niki Werkheiser of NASA’s Marshall Space Flight Center. Their careful review and insightful comments greatly improved this paper. Any inaccuracies in this article are solely the responsibility of the author.

Endnotes

- World Robot Report 2017, Industrial Robots, executive summary.

- Steven Crowe, “Industrial robot sales increase 29% worldwide, IFR reports.”

- Rudrayanan Mukherjee et al., “The Case for In-space Assembly of Telescopes to Support Exoplanet Science,” 2018.

- Iain D. Boyd, Reina S. Buenconsejo, Danielle Piskorz, Bhavya Lal, Elena De La Rosa Blanco, and Keith W. Crane, “On-Orbit Manufacturing and Assembly of Spacecraft,” IDA Paper P-8335, January 2017. https://idalink.org/P-8335

- Ibid.

- NASA. “Study for Commercialization of Low Earth Orbit,” NASA Solicitation 80JSC018LEOCOM.

- Whipple, F. L. “Meteorites and space travel.” Astronomical Journal vol. 52, p. 131 (1947).

- For example, https://www.wimp.com/self-replicating-repairing-robots/.

- H.R.2684 Departments of Veterans Affairs and Housing and Urban Development, and Independent Agencies Appropriations Act, 2000, Sec. 434, “Space Station Commercial Development Demonstration Program.”

- John McCauley, System Integration of Fiber Lasers and Its Effects on Laser Quality.

- For example, Jason Andrews, Krissa Watry, Kevin Brown, “Nanosat Deorbit and Recovery System to Enable New Missions,” 25th Annual AIAA/USU Conference on Small Satellites, SSC11-X-3.

- Danielle Piskorz and Karen Jones, “On-orbit assembly of space assets: A path to affordable and adaptable space infrastructure.” Aerospace Corporation Center for Space Policy and Strategy.

Note: we are temporarily moderating all comments subcommitted to deal with a surge in spam.