The future of commercial space transportationby Dallas Bienhoff

|

| Commercial launch is moving in three different directions today. |

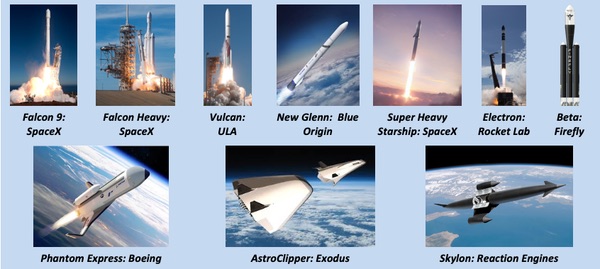

SpaceX’s Falcon 9 and Falcon Heavy reusable booster stages land vertically at the launch site or on sea-going barges. Soon, Blue Origin will join SpaceX when they debut New Glenn with its vertically landing boosters. SpaceX is also developing their Super Heavy/Starliner, a fully reusable two-stage vertical take-off vertical landing launch vehicle.

Other companies are taking their own approaches to reusability. Rather than recovering the entire first stage, ULA’s Vulcan launch vehicle is being designed for first stage engine and avionics compartment recovery. Boeing is working with DARPA to develop a two-stage launch vehicle comprising a reusable winged first stage and expendable second stage. The rocket takes off vertically and the first stage lands horizontally on a runway. Exodus Space is developing AstroClipper, a fully reusable two-stage horizontal take-off horizontal landing launch system.

The holy grail for launch is fully reusable horizontal take-off horizontal landing single-stage-to-orbit vehicles. This dream may be just over the horizon. Reaction Engines, Ltd is developing their Synergistic Air Breathing Rocket Engine (SABRE) applicable to fully reusable single-stage-to-orbit vehicles. In parallel, other companies continue to advance technologies and operational concepts to increase launch rate and drive down launch cost for the small payload launch market.

Commercial launch is moving in three different directions today. The first is already in place and growing: reusable first stages for traditional vertical-takeoff rockets. The second is toward full reusability using vertical-takeoff vertical-landing and horizontal-takeoff horizontal-landing two-stage and single-stage concepts. The third direction is low-cost expendable vehicles for small payloads by applying innovative materials, manufacturing processes, and/or operational approaches. Which solution will win out? Maybe there will be one solution per payload class. Maybe there will be multiple solutions per payload class akin to transportation methods on Earth. There are more than 100 companies pursuing launch solutions; most for small payloads. Some will succeed; some will fail. One thing is certain; the future of commercial launch is going to be different from what it is today.

Cost savings from reusability are somewhat offset by expenses incurred preparing the vehicle for its next flight. Small payload launch vehicles are less costly because they are smaller, built with advanced materials and manufacturing approaches, have higher flight rates, only deliver payloads to low Earth orbit and have a small workforce.

Figure 1. Commercial launch is moving from expendable vehicles to systems with reusable first stages to fully reusable two-stage and single-stage vehicles as well as small, inexpensive expendable vehicles. |

Commercial in-space transportation: a new paradigm

Commercial in-space transportation is in its infancy. Astrobotic has a posted price for delivering small payloads to the Moon. Momentus Space is offering to move payloads to higher Earth orbits from ISS or when attached to a payload at launch. Orbit Fab is testing hardware on ISS for Earth-orbiting water depots. Altius is developing hardware to enable on-orbit servicing and mating. Interglobal is defining intraorbital transportation architecture systems to service co-orbiting space stations. Cislunar Space Development Company is defining reusable cislunar vehicles for transportation from LEO to the lunar surface and all points in between. Reusable space tugs will have the same economic impact benefits that reusable boosters have today.

Space tugs: life extension and orbit transfer

Satellite life extension, where an attached spacecraft takes over for internal attitude control and station keeping capabilities, is an early space tug application. Northrop Grumman’s Mission Extension Vehicle, Effective Space’s SpaceDrone, and DARPA’s Robotic Servicing of Geosynchronous Satellites (RSGS) are programs offering life extension services (Figure 2). Life extension tugs must be delivered to their customer’s location by launch vehicles and upper stages as they don’t have sufficient propellant for major orbit transfer maneuvers.

Figure 2. Life extension and robotic servicing are provided by low-energy space tugs. |

Momentus Space is offering commercial space tugs for small satellite delivery from the ISS or launch vehicle release point. Their Ride family (VIGORIDE, VIGORIDE EXTENDED, and ARDORIDE) comprises low-thrust, stages with high specific impulse (Isp) using water as their propellant. Maximum payload masses are 350, 450, and 4,000 kilograms, respectively. Transportation can be booked on the Ride family today at Momentus’ website. FERVORIDE, a more capable space tug for deploying GEO satellites and interplanetary probes, is under development (Figure 3). Momentus Space VIGORIDE can provide more than one kilometer per second of change in velocity (delta-V) to a 50-kilogram payload while VIGORIDE EXTENDED and ARORIDE can add over five kilometers per second of delta-V to a 100-kilogram and 500-kilogram payload, respectively.

Momentus Space’s Ride family may be the first step in shifting the paradigm of satellite launch by providing more efficient in-space transportation than the upper stages of launch vehicle. In the future, the role of launch vehicles may be limited to getting payloads to Earth orbit where more efficient and reusable space-based transfer stages move payloads to their final destination.

Figure 3. Momentus Space is the first company offering space tug transportation services. |

United Launch Alliance’s Advanced Cryogenic Evolved Stage (ULA ACES) is an upper stage for their new Vulcan launch vehicle. ACES is designed for extended mission durations and refueling. The stage uses liquid oxygen and liquid hydrogen for propellants with a 68-ton capacity. ACES can deliver payloads to geosynchronous orbit or the Moon’s vicinity and return to low Earth orbit for refueling. ULA is currently developing the Vulcan Centaur with a planned first launch in 2021. The Vulcan ACES targeted launch date is in the mid-2020s (Figure 4).

Atomos Space is developing another low-thrust high-impulse space tug for satellite operators. Atomos is solving the last-mile problem in space by providing an in-space transportation service that lowers launch costs for satellite operators.

Figure 4. ULA is developing a long-lived and refuelable cryogenic upper stage for its Vulcan launch vehicle. |

| Expendable space tugs are almost here today, thanks to Momentus Space. Reusable space-based tugs are coming. |

Interglobal is defining space tugs to provide intraorbital transportation services to support ISS and upcoming commercial space stations. Interglobal sees great potential in being able to travel between space stations in the same orbit. The intraorbital transportation architecture includes modular transfer vehicles, pressurized modules and other elements. Interglobal can provide emergency transport from one station to another in lieu of returning the crew to Earth. Interglobal’s space tugs can also transport products from manufacturing stations to orbital warehouses for storage until a cargo return vehicle is available or filled to capacity for return to Earth. This alleviates the need for manufacturing facilities to include product storage volume. A supply depot, or general store, with spare parts, consumables and other sundry items can be a common logistics depot for multiple space stations.

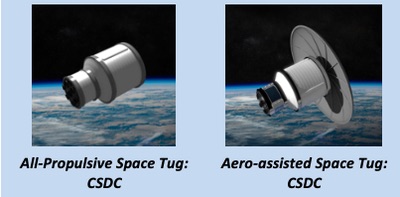

Figure 5. Cislunar Space Development Company is developing reusable LOx/LH space tugs for transportation in cislunar space. |

Cislunar Space Development Company (CSDC) space tugs operate between low Earth orbit and geosynchronous transfer orbit (GTO), GEO, and Earth-Moon Lagrange Point 1 (EML1) (Figure 5). CSDC space tugs pick up customer satellites from a delivery orbit of 185 kilometers altitude or higher, within two degrees of inclination of the space tug’s parking orbit. Maximum payload capacity for CSDC’s GTO and GEO space tugs is four tons; CSDC’s EML1 space tug maximum payload capacity is 25 tons. On-orbit refueling from reusable Earth-to-orbit propellant carriers or LEO propellant depot occurs prior to each mission.

Expendable space tugs are almost here today, thanks to Momentus Space. Reusable space-based tugs are coming. They could be from Atomos, ULA, CSDC, or some as-yet-unknown player. There will likely be low-thrust high-Isp and high-thrust low-Isp systems operating around and between bodies within our solar system to suit the needs of various customers. Space tugs may relegate launch vehicles to just getting payloads into Earth orbit.

Commercial lunar access for payloads and people

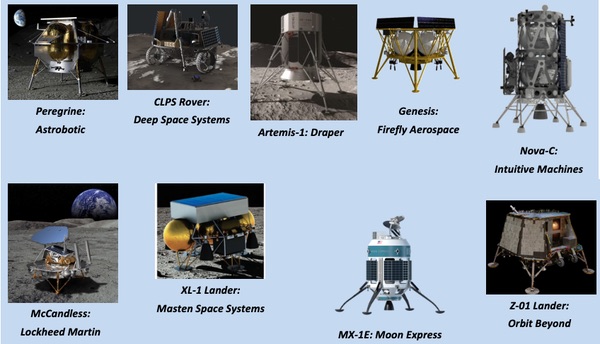

For the purpose of this paper, lunar landers are one-way expendable vehicles that deliver payloads to, and may host payloads on, the Moon’s surface. Moon shuttles are reusable round-trip vehicles that deliver payload to the surface then return to their lunar vicinity parking location or transport humans round trip. Moon shuttles may or may not host payloads while on the Moon’s surface. There are many types of commercial lunar landers and Moon shuttles being pursued today, including: former Google Lunar X Prize (GLXP) competitors, NASA Commercial Lunar Payload Services (CLPS) awardees, NASA Human Landing System broad agency announcement (BAA) awardees, upcoming NASA Ascent Element BAA bidders, and purely commercial approaches.

Former Google Lunar X Prize competitors

The Google Lunar X Prize, established in 2007, had a $30 million prize purse. Google canceled the prize in 2018; the initial deadline was in 2014. Twenty-nine teams registered for the prize; 26 teams from 10 different countries plus three international teams. In the end, there were five finalists: Hakuto (Japan), Moon Express (US), Team Indus (India), SpaceIL (Israel), and Synergy Moon (international). SpaceIL launched in April 2019, achieved lunar orbit but suffered an engine failure during descent. Astrobotic, iSpace (Hakuto), Moon Express, and PT Scientists continue to pursue their commercial lunar lander plans (Figure 6).

Figure 6. Lunar lander concepts from the five finalists pursuing the Google Lunar X Prize. |

NASA Commercial Lunar Payload Services awardees

In November 2018, NASA awarded nine companies Indefinite Delivery Indefinite Quantity contracts with a combined maximum value of $2.6 billion over the next ten years for lunar payload delivery. The companies are: Astrobotic (Pittsburgh), Deep Space Systems (Littleton, Colorado), Draper (Cambridge, Massachusetts), Firefly Aerospace (Cedar Park, Texas), Intuitive Machines (Houston), Lockheed Martin (Littleton, Colorado), Masten (Mojave, California), Moon Express (Cape Canaveral, Florida), and OrbitBeyond (Edison, New Jersey). Payload capacity varies from 35 to 500 kilograns (Figure 7). Each company received an unspecified amount of funding to develop their payload users guide.

Figure 7. Lander concepts from the nine awardees for NASA’s Commercial Lunar Payload Services opportunity. |

On May 31, NASA awarded $273.5 million for the first three delivery service contracts to the Moon to Astrobotic, Intuitive Machines, and OrbitBeyond. Astrobotic received $79.5 million for its proposal to fly as many as 14 payloads to Lacus Mortis, a large crater on the near side of the Moon, by July 2021. Intuitive Machines won $77 million to fly as many as five payloads to Oceanus Procellarum, a scientifically intriguing dark spot on the Moon, by July 2021. Orbit Beyond’s $97 million award is to fly as many as four payloads to Mare Imbrium, a lava plain in one of the Moon’s craters, by September 2020. Unfortunately, OrbitBeyond had to withdraw from their NASA contract on July 29 because it could not meet its planned milestones due to internal conflicts.

NASA Human Landing System BAA awardees

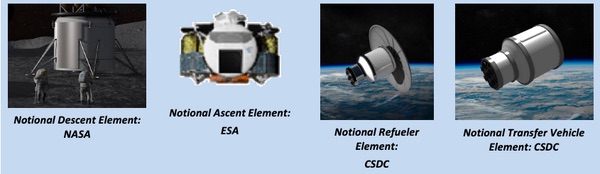

Following the Trump Administration’s direction to NASA to return humans to the Moon before going on to Mars, NASA released their NextSTEP 2 BAA Appendix E: Human Landing System on February 7. Appendix E defined NASA’s Reference Human Landing System Architecture, comprising a Descent Element, Transfer Vehicle Element, Refueling Element, Ascent Element, and Surface Suit Element. Proposals were to include concept studies and prototypes for the Descent, Transfer Vehicle, and Refueling Elements targeting a human lunar landing in 2028 (Figure 8).

Figure 8. Notional concepts for NASA’s Human Landing System Reference Architecture. |

Proposing companies had to be able to develop their proposed systems and contribute at least 20% (large companies) or 10% (small companies) of the proposed price with 50% of the contribution provided during the six-month study period. Maximum award value was set at $9 million with the majority of funds allocated to the Descent Element. On May 16, NASA awarded $45.4 million total to 11 companies:

- Aerojet Rocketdyne – Canoga Park, California

- Blue Origin – Kent, Washington

- Boeing – Houston

- Dynetics – Huntsville, Alabama

- Lockheed Martin – Littleton, Colorado

- Masten Space Systems – Mojave, California

- Northrop Grumman Innovation Systems – Dulles, Virginia

- OrbitBeyond – Edison, New Jersey

- Sierra Nevada Corporation, Louisville, Colorado, and Madison, Wisconsin

- SpaceX – Hawthorne, California

- SSL – Palo Alto, California

These awarded efforts, which were to start in July 2019, may lead to follow-on public-private partnership awards similar to commercial cargo and crew for the ISS. NASA and selected companies will both fund development cost followed by a competition for service contracts with awards to one or more companies.

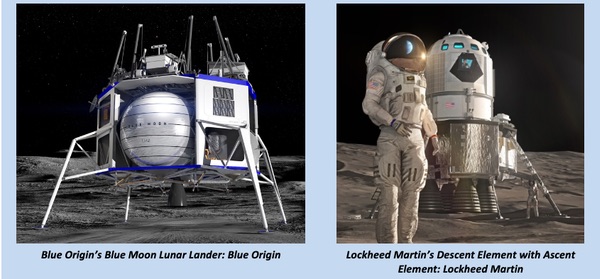

Two companies have presented their Descent Elements to the public: Blue Origin and Lockheed Martin (Figure 9). Blue Origin first publicly disclosed their expendable Blue Moon in March 2017. On May 9, Jeff Bezos unveiled a full-scale mockup at the Satellite 2019 conference. Blue Moon uses liquid oxygen and liquid hydrogen for propellants and has a 3.6-ton payload capacity. A stretched version could land 6.5-ton. Blue Moon is analogous to a flatbed truck with the payload sitting on the top surface. Lockheed Martin presented their two-stage lunar lander/ascent stage at the 2019 Space Symposium in Colorado Springs, Colorado.

NASA Ascent Element BAA opportunity

On March 26, the day after the Human Lander System BAA proposals were submitted, the Trump Administration, via Vice President Pence’s speech at NASA’s Marshall Space Flight Center, doubled-down on putting US astronauts on the Moon before going to Mars by calling for the human landing to occur before the end of 2024. NASA’s response to Pence’s challenge was to issue an update to their April 8 Ascent Element pre-solicitation synopsis on April 26. NASA had targeted the end May for releasing Appendix H. Companies awarded studies under Appendix E are likely to submit proposals for Appendix H, among others.

Figure 9. Two descent stage concepts that align with NASA Human Landing System Reference Architecture. |

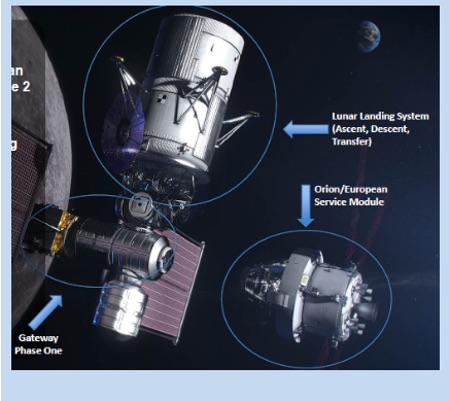

NASA released the draft Appendix H, entitled Human Landing System Integrated Lander, on July 19 and held a Virtual Industry Forum on July 22. While NASA’s reference architecture for accessing the Moon includes a Transfer Vehicle Element, Descent Element, and Ascent Element, bidders may propose other solutions (Figure 10). Options include a two-stage approach using a Descent Element and an Ascent Element, a single stage concept operating round trip between Gateway and the lunar surface with or without an integrated crew module. NASA will not be taking ownership of the proffered Integrated Lander. Instead, this is a Public-Private Partnership with bidders contributing 10% of their proposed development costs then bidding for future lunar landing missions as a commercial service.

Figure 10. NASA’s Gateway, Orion and Lunar Landing System concept for 2024 human lunar mission: NASA |

Future Moon shuttles

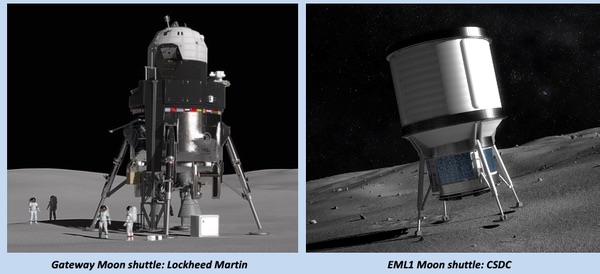

Moon shuttles differ from NASA-identified Descent Elements and Ascent Elements by being roundtrip vehicles between a lunar-vicinity staging point and the lunar surface. Two companies have publicly discussed Moon shuttles: Lockheed Martin and CSDC (Figure 11).

| Access to the Moon, whether for science and technology payloads or humans, has moved away from NASA-owned spacecraft to commercial companies selling rides to NASA. |

Lockheed Martin presented their Moon shuttle concept at the 2018 International Astronautical Congress in Bremen, Germany. Lockheed Martin’s Moon shuttle delivers four crewmembers and one-ton payload to the Moon for a two-week stay. It does not require surface maintenance or refueling before returning to the Gateway. The vehicle provides five kilometers per second total delta-V using liquid oxygen and liquid hydrogen as propellants with a 450-second specific impulse. Lockheed Martin says the vehicle mass is 62 tons when loaded with propellant and 22 tons when empty.

Figure 11. Two resuable lunar lander, or Moon shuttle, concepts; one with an integrated crew module and one after off-loading a payload, which could be a crew module. |

CSDC’s Moon shuttle is sized to deliver 25 tons from EML1 to the Moon’s surface and return with zero payload without refueling. Delta-V is 2,520 meters per second each direction. The propellant combination is liquid oxygen and liquid hydrogen with a specific impulse of 450 seconds. CSDC’s Moon shuttle propellant capacity is between 49 and 69 tons and its dry mass is between 9 and 16 tons, depending on assumed design margins. The CSDC Moon shuttle can carry up to 13 tons roundtrip between EML1 and the lunar surface.

Access to the Moon, whether for science and technology payloads or humans, has moved away from NASA-owned spacecraft to commercial companies selling rides to NASA. Nine companies are currently eligible to offer lunar payload delivery services to NASA and NASA has awarded delivery contracts to three companies under the Commercial Lunar Payload Services solicitation. NASA’s NextSTEP BAA: Appendix H, Integrated Human Landing System, calls for companies to develop systems for human access to the lunar surface from Gateway. Companies must contribute 10% of the proposed development cost in exchange for retaining ownership and an opportunity to compete for future missions. Reusability requirements (five uses) and mission opportunities (five over ten years) may be insufficient for a robust commercial transportation service to the Moon.

Supporting infrastructure

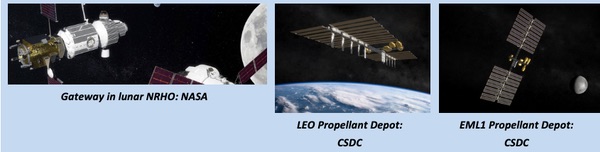

Transportation architectures need supporting infrastructure. Motor vehicles need roads, gas stations, maintenance shops and tire stores, to name a few. Railroads need tracks, fuel depots, electric lines, and switching yards. Ships need tug boats, loading docks, and fuel sources. River transportation needs tug boats, barges, canals, loading docks, and fuel depots. Likewise, commercial in-space transportation needs docking facilities, refuelers, propellant depots, personnel modules, and propellant tankers (Figure 12).

Figure 12. Infrastructure is important in transportation networks; the Gateway is NASA’s node between in-space systems and lunar landers while CSDC’s propellant depots are nodes between Earth-to-orbit, in-space, and lunar lander systems. |

| For truly sustainable, operable, and effective transportation between Earth and the Moon, an integrated cislunar transportation architecture is needed, one that separates Earth-to-orbit launch, orbit transfer, and lunar surface access, using reusable in-space vehicles and propellant depots in low Earth orbit and near the Moon. |

The Gateway is NASA’s supporting infrastructure for Moon and Mars missions. Its initial components include a power and propulsion element and habitation element. Gateway provides docking ports for Orion, a Human Landing System, and a logistics module in its initial configuration. Gateway is a transportation node where people and goods transfer between vehicles from Earth (Orion and logistics modules) and a Human Landing System, which operates between Gateway and the Moon. NASA is preparing a Gateway Logistics Services Request for Proposal for delivering supplies to Gateway similar to the successful Commercial Transportation Services contracts for ISS. The final RFP for that effort was released August 16.

Cislunar Space Development Company has defined other infrastructure to support its space tugs and Moon shuttles. Earth to orbit refuelers deliver liquid oxygen and liquid hydrogen to GTO and GEO space tugs for just-in-time refueling, or water to LEO propellant depots. Propellant depots in LEO and at EML1 produce liquid oxygen and liquid hydrogen from water and provide docking facilities for space tugs and Moon shuttles between missions. Space tugs carry liquid oxygen and liquid hydrogen or water tankers from LEO to EML1, and Moon shuttles deliver water tankers to EML1 from the Moon. Personnel modules are space tug and Moon shuttle payloads for human exploration and space tourism missions from LEO to the Moon and points in between.

Closing thoughts

Commercial space transportation today consists of launch services and cargo delivery to the International Space Station. In addition, two companies have posted prices for commercial space transportation services; one to the Moon and one to higher orbits from the International Space Station or launch vehicle release points. Soon there will be commercial rides available for adventure travelers and astronauts on suborbital flights and to the ISS. By 2024, according NASA’s Integrated Landing System BAA, transportation from Gateway to the Moon will be a commercial service. Several companies are developing concepts for commercial transportation in cislunar space and throughout the solar system. However, for truly sustainable, operable, and effective transportation between Earth and the Moon, an integrated cislunar transportation architecture is needed. CSDC believes an integrated cislunar transportation architecture is one that separates Earth-to-orbit launch, orbit transfer, and lunar surface access, using reusable in-space vehicles and propellant depots in low Earth orbit and near the Moon. The architecture uses liquid oxygen and liquid hydrogen produced from Earth-launched water until water is economically available on the Moon. Hang on to your helmet as commercial space transportation for satellites, logistics and people is about to hit escape velocity.

Note: we are temporarily moderating all comments subcommitted to deal with a surge in spam.