Passive space debris removal using drag sail deorbiting technologyby Rebecca Hill

|

| Spencer believes the “sweet spot” for passive debris removal is for small satellites and launch vehicle upper stages in orbits between 500 and 900 kilometers |

But with a projected 57,000 new satellites expected to launch by 2029, the question becomes: how to prevent new debris? Currently, at Purdue University’s School of Aeronautics and Astronautics, David Spencer and his team are working on a passive debris removal system using drag sail deorbiting technology where these passive deorbiting systems are embedded within a spacecraft for deorbiting at the end of the spacecraft’s lifetime.

Licensed by Vestigo Aerospace and funded through a Purdue University Research Foundation grant, Spencer and his team hope to launch a drag sail prototype with Texas-based Firefly Aerospace, no earlier than this April. Right now, Spencer is the project and mission of LightSail 2, a solar sail currently in orbit.

According to Spencer, the drag sail would launch within a satellite or attached to launch vehicle upper stage. Once the vehicle reaches the end of its operational lifetime, the sail would deploy, using aerodynamic drag as a deorbiting force. While traditional deorbiting requires burn maneuvers, a passive deorbiting system works independently of spacecraft propulsion.

Spencer believes the “sweet spot” for passive debris removal is for small satellites and launch vehicle upper stages in orbits between 500 and 900 kilometers. They can be used up to an altitude of 1,000 kilometers, but above that altitude the size of the drag sail size increases dramatically, creating a risk of collision with other debris. I”t’s a big target, so to speak,” said Spencer. Thus, his team is concentrating right now on that sweet spot for drag sails with 1U and 3U cubesats.

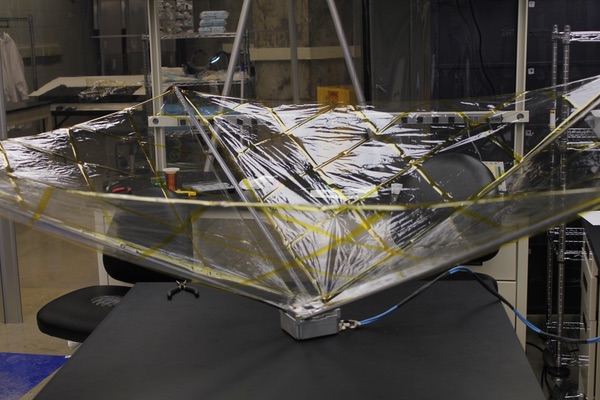

In many ways, drag sails are like solar sails. The sail material is thin. It is packed within a satellite, and carbon fiber booms stabilize the sail. However, while solar sails use the Sun’s photons for propulsion, photons destabilize a drag sail. To work, sail orientation must be face-on to the aerodynamic flow to achieve maximum drag.

| The biggest user may be the megaconstellations of communications satellites for global Internet services, where each satellite in the constellation would require a drag sail unit. |

In development are two types of sails. One is Spinnaker 1, a cubesat-class sail 1.8-meters square that, when looking face-on, forms a square pyramid with an open funnel. “It’s a fairly small sail and effective for deorbiting cubesat spacecraft like the 10x10x10 centimeter satellite,” said Spencer. Up to 27U cubesats can be deorbited with a sail this size, says Spencer.

The sail material is a transparent, Saran Wrap-like material called CP-1, tested and rated for a ten-year life span in geosynchronous earth orbit. The translucent material allows solar photons to pass through the material rather than being deflected, like it does with a solar sail.

Spencer’s team is also developing an 18-square-meter flat sail with booms three meters long, called Spinnaker 3. With this large area, Spencer says it can deorbit 400-kilogram satellites or launch vehicle upper stages from orbits as high as 600 kilometers. This sail is scheduled to launch with Firefly Aerospace no earlier than April.

With the transparent sail material came several challenges. Static cling made tightly folding the sail difficult, says Spencer. That same static cling could also create a buildup of static electricity on the deployed sail, he said, resulting “in an electrical arcing that could damage sensitive electronics in drag sail avionics.” Another concern involved ensuring that the sail resisted the pull of the three-meter carbon fiber booms to avoid tearing the sail on deployment.

One critical aspect with the drag sail was the structural stiffness of the carbon fiber booms. “We wanted to make sure that the booms deployed in a repeatable fashion in their rigid configuration on deployment to achieve drag sail structural stability,” said Spencer. “It’s taken us a few iterations to get there, but we’ve done enough testing to look like everything is going well.”

Rip stops built within the sail will also help decrease the probability of damage in the event of a collision with space debris. “Micrometeoroids can pass through the sail material without minimal consequences and most likely would result in pinholes that wouldn’t have much impact,” said Spencer. However, larger debris could result in debris fragmentation, which is why, says Spencer, they needed to meet the 25-year deorbit guidelines and collision probability requirements.

Aerodynamically, Spencer’s goal was stabilizing the drag sail design so it would trim to a maximum drag orientation. In multiple design simulations, Spencer’s team found that the sail achieved aerodynamic stability at low altitudes, below 400 kilometers. But above that, “the vehicle was basically tumbling,” he said, “which was okay because it will still provide more area and more rapid deorbit than it would without a sail.”

Right now, Spencer is looking to attract developers and launch vehicle companies. But the biggest user, in Spencer’s opinion, is the megaconstellations of communications satellites for global Internet services, where each satellite in the constellation would require a drag sail unit. “Vestigo Aerospace is designing our drag sails to have standard mechanical and electrical interfaces, resulting in straightforward integration with the host vehicle,” said Spencer.

| “For new spacecraft that are being launched today and in the future,” said Spencer, “having the capability to deorbit at the end of the mission makes sense.” |

As for reentry, drag sail technology uses a one-time deployment system, initiating at the end of the vehicle’s lifetime or before. One benefit of drag sails is that the host spacecraft need not be functional. A timer stored within the avionics unit will initiate deployment and can be updated as needed by the host spacecraft operator.

Though Spencer’s team will not pursue targeted reentry objectives for these first two prototypes, his team is working on the option of deploying the drag sail when the host satellite is close to reentry, at an altitude of less than 200 kilometers. “The goal is to constrain the atmospheric entry corridor so that reentry occurs over unpopulated areas, away from highly trafficked air corridors,” said Spencer. NASA developed the Exo-Brake Parachute technology on the same principle.

While the utility for drag sail is clearly apparent, Spencer believes sooner or later that regulations will catch up to future space applications, requiring deorbiting systems. “For new spacecraft that are being launched today and in the future,” said Spencer, “having the capability to deorbit at the end of the mission makes sense.”

Note: we are temporarily moderating all comments submitted to deal with a surge in spam.