Interview: two guys at the vanguard (part 2)by Sam Dinkin

|

| They blew their development budget by 100%… and they made the program manager the president of the company. |

How many twin-engine planes, twin-engine large transports, has Boeing designed before? They had a well-calibrated designed system. They had a team of engineers who had done this. They knew exactly what they were doing. They were just turning the crank.

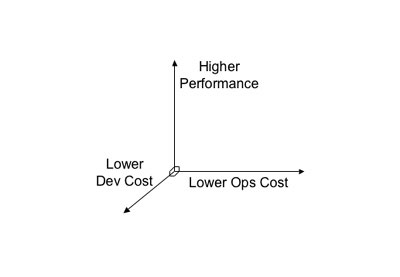

We don’t have a calibrated design system. We have a team that never worked together before, and we are doing a vehicle that a lot of people haven’t done anything like it. We probably can’t even hit an arbitrary point on the face. All I think we can do is we can hit one axis. So which one should I go for?

TSR: If you have a limited development cost, you can get much lower operating costs than the satellites even if it is not $100,000 or whatever your goal happened to be. On your flight performance, if you only go up to 50 miles, you’ll still get great pictures.

Renaud: I don’t think I am going to be able to do what’s called “design to cost”. I don’t really know going in how much it’s going to cost. I don’t think I am capable of [hitting the budget exactly.]

TSR: You would have to be very conservative on your cost usage in order to hit it.

Renaud: If you look at the life of a vehicle, the long term life of a vehicle that is designed for operations. The day-to-day operating cost far outweigh what you spend to design and build the vehicle. [The ops axis is] where we want to be.

Our philosophy is drive out this axis. Ignore [the performance] axis. Try to contain [the development cost axis], but to first order, ignore that too; it’s gonna cost what it’s gonna cost.

Renaud: We control [dev costs] this way: we bought second hand furniture for literally pennies on the dollar from a company that was shutting down. That chair you’re sitting in I picked up used. The rug came from Home Depot.

TSR: I need to finish my office in this stuff. I buy stuff new and it isn’t half as nice.

Pat Bahn (CEO of TGV Rockets): There are companies that spend weeks selecting nice furniture, then go out of business.

Renaud: Then we go buy their furniture. I wanted the desk from the CEO of Iridium. I really, really wanted it. Then we wanted to hang it over Pat’s head as a symbol of overhead. We call it the desk of Damocles.

All of our design choices, everything, day-to-day, is operability. Operability. All ops cost. When an engineer goes, “I want to do this change. I think I can get the weight down on the vehicle if we just go to light propellant.”

And I go, “What’s that got to do with operability?”

| Somebody is paying you to get international astronaut wings, and you get them to 99.5 kilometers—you’re in trouble. |

Consider a hydrazine thruster. You go with any kind of modified thruster for attitude control on a vehicle, your performance goes through the roof. You go from a huge gas bottle down to this little thing and a little tiny thruster. You get way more performance out of it. But all of a sudden, you’ve got guys in space suits, hazmat trucks. If the vehicle goes down off-field, forget about any simple recovery operation.

So this is what we do all day every day. We drive the operability axis.

Graceful degradation of performance

Renaud: We are designing our vehicle to go to some altitude. We’d like it to go to 100 kilometers. Will it make that? I don’t know. Probably not. Because as we go through the process, I am continually making decisions against flight performance.

TSR: Even if it goes to 90 kilometers it’s worth a lot to the military.

Renaud: That’s the thing about a suborbital vehicle. If you’re building an orbital vehicle, if it doesn’t go to orbit, you failed. You’ve lost your vehicle, you’ve lost your customer, you’ve lost your payloads.

TSR: And so we see a lot of zeros.

Renaud: Tourism is like that too. It’s suborbital, but somebody is paying you to get international astronaut wings, and you get them to 99.5 kilometers—

TSR: Like the SpaceShipOne flight where they made it [to 100 kilometers] by the skin of their stabilizer?

Renaud: —You’re in trouble.

TSR: They want their money back.

Renaud: Even [for suborbital tourism] you’ve got to pay an awful lot of attention to the performance. If you are just going after microgravity and taking pictures. You [intend to] go to 50 miles, but if you only go to 48 miles, no big deal. If somebody’s paying you for four minutes [of microgravity], and you come back and you go, “Gee, I could only get you three and half.” [They’ll say] “I am only going to pay you [7/8] of what I was going to pay you.” You go, “OK.”

Renaud: It’s a very graceful degradation. It allows you drive down that operability axis.

TSR: If you see what’s being built now, you have the Internet with graceful failure and cell phones with graceful failure.

Renaud: I don’t know about cell phones. I’ve gotten screeched at lately.

TSR: Compare it to Ma Bell. 5k that fails pretty gracefully compared to a 16, 32 or 64 kb/s frame where—

Renaud: You lose.

TSR: —You lose the circuit.

| In HTVL or VTHL you have to do a flight mode change in abort cases. Yikes. |

Renaud: It’s the same kind of philosophy. You are trying to look at ways to trade performance and a graceful degradation in your marketability for ops cost, because there is only so much you can charge for these services. As your ops cost goes up, your margin goes down. For a business, especially a new business that’s doing product development, your margin is life. Just like for a fighter pilot, speed is life. As you lose that operability, as your ops cost starts going up, your margin goes down. You want to go into this doing everything you can to cut your operability.

Orientation

TSR: Michelle-B, because it’s new and you guys put some thought into it, has got some new stuff. How did you guys dream up popping out a reusable drag surface?

Renaud: We wanted the vehicle stable going up. We want the vehicle to be stable going down. You don’t want it tumbling. You don’t want it to come down nose first. You know it’s stable going up nose first, so you know it going to be stable if you don’t do anything to the vehicle it’s going to be stable going down nose first. That’s generally bad. You go really fast and leave a hole in the ground. So you’ve got to do something to change the configuration.

You’ve got to move your center of gravity or something to get into a high-drag configuration. There are a number of ways to do that. We’re still not exactly sure on what’s the best way to go there.

Bahn: When I first laid out the requirements for the vehicle, they were basically high-level requirements. I did put in one or two low-level requirements. One of them was an integrated flight model. It was either going to be vertical takeoff, vertical landing (VTVL) or HTHL. None of this turnaround landing. If you are always going in the same way, you simplify your structural challenges, your design challenges.

Renaud: And, most importantly, abort. In HTVL or VTHL you have to do a flight mode change in abort cases.

TSR: Yikes.

Renaud: Yikes. Yeah. If you’re a VTHL and you lose your engines 10 seconds off the pad, you don’t have enough horizontal velocity to fly. You don’t have enough altitude to glide if you could manage to get flying.

TSR: You don’t have enough altitude to shoot people out in parachutes.

Renaud: It’s bad. That drives VTVL or HTHL for the abort and the operability of it. If you have to take your vehicle [once it lands] and change its orientation, how many people does that take? You need to pick it up at a minimum. If you do it with a crane, that’s six people: you need a guy on a crane, you need three guys on ropes, you need a guy waving his hands and a guy in the control booth. All those guys eat up a load of costs: a hundred, a hundred fifty thousand a year each. There’s a half-million dollars in fixed costs. Think about it. Just those crane guys is a good example. There’s a half-million dollars in fixed cost. You fly once a month, which if you’re a startup space company and you’re flying every month—

TSR: That’s awesome.

Renaud: That’s awesome. But that’s 12 times. You’ve got right there $40,000 per flight in ops cost just to turn your vehicle from horizontal to vertical. You’ve really, really got to think about this stuff to drive the ops cost down. You’ve got to think how many people is it going to take to do every single operation. You can throw out a chute. How big is a chute that is going to hold a 20,000 pound vehicle?

TSR: That’s a lot of packing.

Renaud: How many people does it take to pack that? And how long does it take to pack it? Can you do a four-hour turnaround with that chute?

TSR: No way, you need an extra chute.

Renaud: Right. Even getting a pre-packed chute that size onto a vehicle with some assurance that it will work is probably more than a four-hour operation. No chutes. You can’t be shedding parts. You can’t have anything that takes a lot of people to operate. It’s got to be very, very simple.

TSR: That really drives you to—

Renaud: HTHL or VTVL. You have to be able to bring the vehicle down in a high-drag configuration stably. Burt came up with an easy way to do it for an airplane. You swing the tail up and come down flat. We’ve got a good way to do it. We’ve got a couple of good ways to do it.

TSR: I like the pictures you have that make it look like a badminton shuttlecock.

Renaud: Where we end up with that, I don’t know. We’re going to end up with probably one of four [design choices]. But until I start building stuff, the jury’s still out on what it is. Again, I am going down that operability axis. I am going to look at what is easiest to maintain.

TSR: The easiest to fold back up. The whole works.

| So this is what we do all day every day. We drive the operability axis. |

Renaud: It’s got to fold up by itself. Largely, you’re driven by maintainability and inspectability. If it takes hydraulics to do it, those are hydraulic lines that have to be checked and inspected and looked for leaks. That sort of thing. Wiring has to be checked. Where you end up with it is a design task.

TSR: So there’s no way you can get maintainability down to like my car out front where it self tests.

Renaud: Absolutely. But you’re not going to get it down to a car, you’re going to get it down to an aircraft.

TSR: But you don’t want to make it so they have to take the engine out to inspect it.

Renaud: DC-X was ready to go after eight hours.