Launch failures: fairingsby Wayne Eleazer

|

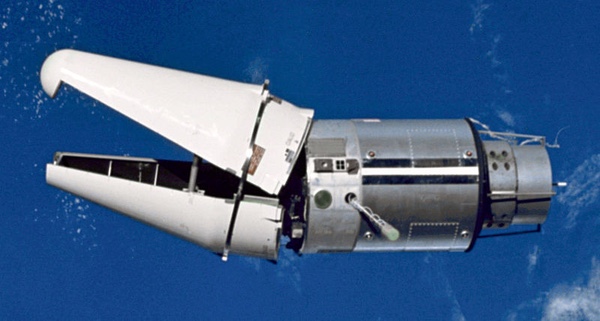

| When GT-9 rendezvoused with the target they found that an electrical connector apparently had failed to separate and the payload fairing was hung up, partially open, in what became known as the “Angry Alligator.” |

A payload fairing’s failure to separate happens rarely but is just one mode of failure for that component. Payload fairings can also separate from the vehicle early, fall apart on ascent, or produce debris that damages the spacecraft. Fairings are deceptively challenging items. They have to stay firmly attached and protect the payload but separate and fall cleanly away on command. They appear simple in concept, but they are very challenging to implement in fact. As the Astra launch illustrated, people are still trying to figure out how to make a fairing stay on for the first phase of the ascent and yet come off at the right time. Some clever techniques have been used as well as simple brute force. The favorite fairing for years employed by Titan IV and Delta vehicles featured the McDonnell Douglas “isogrid” intricately machined structure, based on the design used by the Thor ballistic missile tank structure. Lockheed developed a very clever method of both sealing the joint between the fairing halves and causing them to separate at the proper time, called “SuperZip”, rather like a string of firecrackers in a garden hose. Other companies came up with the same SuperZip idea only to find that someone else had gotten there first and patented it.

There are some unique requirements for fairings. They have to be robust, a requirement that can be met with either metal or composites, but have to be insulated against transmitting heat and sound to the payload while allowing radiofrequency signals to go both ways. And while they need to be insulated with what are usually non-metallic materials, they also have to conduct electricity along the outer surface to prevent electric charge buildup that can cause “St Elmo’s Fire” to damage the payload; this requirement led to the Titan II fairing being unable to withstand some of the very conditions it was designed to protect against. Passing through a cloud that had freezing conditions that would produce such charging would erode the protective layer on the fairing even before the charging conditions occurred.

For some spacecraft carrying optical sensors, the inside of fairings have to be very, very clean, an operation akin to using Q-tips to wash a city bus. And for spacecraft that are encapsulated in the fairing before launch, the cover also has to protect them during that phase of transport as well; on one memorable occasion a fairing had to deflect a traffic light that no one noticed was in the way.

On the other hand, the fairings used by the Atlas E/F and H vehicles used a straightforward aluminum skin and stringer structure that could have been from World War II: large rectangular blocks attached to the fairing externally to secure it together, some cork on the outside to insulate it, and some really big springs to push it apart. It was perhaps a bit crude and clunky looking compared to other sleeker designs, but it worked perfectly every time.

| Subsequent investigation revealed that a company that provided some of the aluminum material used in the fairing system had falsified the test results. Indications are that the material deficiency was responsible for both Taurus failures. |

Almost certainly the first payload fairing problem to achieve international fame occurred on the GT-9 Gemini Titan mission. Launched in June 1966, the objective was to develop the rendezvous and docking techniques that would be vital for the Apollo Moon missions. Originally the plan was for the Gemini spacecraft to dock with an Agena, but when that Agena failed during ascent they launched a backup target vehicle, an Augmented Target Docking Adapter, on an Atlas booster. When GT-9 rendezvoused with the target they found that an electrical connector apparently had failed to separate and the payload fairing was hung up, partially open, in what became known as the “Angry Alligator.”

Failure to separate payload fairing

Aside from the recent Astra launch, there have been only five instances of payload fairings failing to separate over the last 46 years. On January 23, 1981, a Tsiklon 3 booster suffered a mission failure when the payload fairing failed to separate. On April 27, 1999, an Athena 2 booster carrying the Ikonos-1 spacecraft failed to deliver its payload when the payload fairing did not separate properly. It appears that the shock imparted by the payload separation ordnance dislodged the cable that sent signals to the ordnance that was designed to split the fairing, thus the fairing was disconnected from the booster but failed to peel away as designed. On August 25, 2009, the first KSLV-1 Naro launch vehicle was launched by South Korea. Apparently, half the payload fairing failed to separate during ascent, and the extra mass led to the payload re-entering.

Then there is the Taurus experience with the failure mode. On February 24, 2009, a Taurus XL 3110 booster carrying the Orbiting Carbon Observatory payload failed to place the spacecraft in orbit when the payload fairing failed to separate. Orbital Sciences Corp conducted an investigation, identified a number of possible problems, and implemented corrective action, including some component redesign. Two years later, on March 4, 2011, another Taurus XL 3110 launched the Glory E1P Hermes KySat-1 mission. The result was another mission failure when the payload fairing again failed to separate. Subsequent investigation revealed that a company that provided some of the aluminum material used in the fairing system had falsified the test results. Indications are that the material deficiency was responsible for both Taurus failures and the company was fined as a result.

Premature payload fairing separation

Surprisingly enough, there are very few known instances in which the payload fairing came off too early. The only known example occurred on the second of the very few Volna vehicle launches, carrying the second Inflatable Re-entry and Descent Technology (IRDT) payload on July 12, 2002. The payload was never recovered and the conclusion was that the payload fairing had come off early and damaged the payload prior to separation.

Admittedly, payload fairings have been known to come off too early when some other kind of failure occurred, such as the Atlas 19F NOAA-B failure of May 29, 1980, and the Delta 3914 GOES-G failure of May 3, 1986, but the fairings were not the cause of the failures.

Payload fairing structural failure

The most common payload fairing problem is some kind of structural failure of the fairing during ascent. This may or may not impede the payload from attaining orbit.

| Payload fairing failures are rare but do represent a hurdle all programs have to clear to ensure success. |

On August 6, 1981, Atlas Centaur AC-59 carried the FLTSATCOM 5 spacecraft into orbit. Once up there the new comm bird was not working too well and had to be given TLC by the ground stations for its whole life. Investigation and experimentation revealed that the strength calculations for the fiberglass fairing did not reflect the fact that it contained sea level atmospheric pressure within the fiberglass cells. At high altitude, the inner layer of the fairing expanded inwards, damaging the spacecraft. Following that failure General Dynamics added silicone rubber insulation on Atlas booster structures that might be affected by aerodynamic heating at higher altitudes.

On December 21, 1992, the third flight of the Long March 2E booster, carrying the Aussat B2 and Optus B-2 spacecraft, was marred by a collapse of the fairing during ascent at T+48 seconds, resulting in severe damage to the spacecraft. Nonetheless, the remains of the two spacecraft were delivered to orbit. The Chinese blamed the failure on the spacecraft exploding and destroying the fairing rather than the reverse. It appears that the high-altitude winds were higher than expected and the wind shear destroyed the fairing.

On January 25, 1995, the fifth launch of the Long March 2E booster failed to deliver its payload, the Apstar 2 spacecraft, to orbit. The failure appeared to be nearly identical to the failure on the third flight, and occurred at T+51 seconds. In this case the fairing collapse caused the spacecraft propellant tanks to leak and the resultant explosion caused the vehicle to go out of control and impact a populated area, causing casualties.

On May 14, 1995, a Soyuz 11A511U booster carrying the Kometa 18 Yantar-1KFT payload suffered a payload fairing collapse at T+49 seconds. The vehicle veered off course and the automatic destruct system shut down the engines. Then on June 20, 1996, the exact same failure occurred with a Soyuz 11A511U carrying the Yantar-4K1 payload, the failure occurring at T+51 seconds. An investigation concluded that both these failures were due to a defective manufacturing process that resulted in weak glue bonds in the fiberglass material of the fairings.

On July 9, 1997, a Delta II 7920 booster lifted off from Vandenberg AFB with a payload of Iridium spacecraft. One spacecraft did not respond to commands after attaining orbit and the conclusion was that some of the insulation material in the fairing had come loose and damaged the payload.

So, payload fairing problems are in fact comparatively rare compared to more common failure modes, such as engine problems, but do represent a hurdle all programs have to clear to ensure success.

Note: we are using a new commenting system, which may require you to create a new account.