The difficult early life of the Centaur upper stageby Trevor Williams

|

| Problems during development severely disrupted America’s planetary mission plans, leading to none other than Wernher von Braun threatening to kill the stage. |

A key parameter that measures the performance of a rocket engine is its specific impulse, which is proportional to the exhaust speed of the rocket. The design choice that is most important in determining specific impulse is the fuel/oxidizer pair that the engine uses; other design parameters, notably combustion chamber pressure and nozzle area ratio, also affect it, but to a far lesser extent. Fuel and oxidizer combinations with high specific impulses that were studied in the 1950s included hydrazine/fluorine, hydrogen/fluorine, and hydrogen/oxygen. Hydrogen/fluorine showed promise, but an incident in a Lewis Research Center test chamber in May 1958 illustrated the practical problems that can result from the fact that fluorine reacts readily with virtually any material. A small leak through a stainless steel joint produced a column of fluorine that reacted “with everything in its path” [1, p. 198], including the joint, a pipe, and the water vapor in the air. This helped to reinforce the conviction of Abe Silverstein, the key NASA proponent of high-energy propulsion, that the hydrogen/oxygen combination was the preferred option.

Kelly Johnson with U-2 reconnaissance aircraft. (credit: US Air Force) |

One apparent hurdle was the difficulty of producing and handling large quantities of liquid hydrogen. Even as late as the early 1950s, liquid hydrogen was still basically a laboratory curiosity, dealt with (carefully!) in very small quantities. However, in early 1956 Clarence “Kelly” Johnson, the legendary chief designer of the Lockheed Skunk Works, submitted a proposal to the Air Force for a supersonic successor to the U-2 spy plane: this would be propelled at over Mach 2 by a jet engine modified to operate on liquid hydrogen [2, p. 170]. This necessitated that Lockheed learn practical ways to produce and store liquid hydrogen: Johnson put Ben Rich in charge of this development. Rich soon learned that the current state of the art of operating with hydrogen was not adequate, and so Lockheed developed new approaches. The new reconnaissance aircraft design was called the CL-400, with the overall program being referred to as Suntan. Pratt & Whitney was responsible for the development of the Suntan engine: first was a J-57 turbojet modified to run on liquid hydrogen, and later the Model 304 engine. Suntan was classified at a level above Top Secret, with only 25 employees at the company being cleared to see the details. As a result of this level of classification, the total cost of Suntan is unclear: it has only been pinned down to the range $100–250 million [1, p. 165].

After further work, it became clear to the developers that the CL-400 would have an inadequate range of about 2,000 kilometers. This was a consequence of the low density of liquid hydrogen and could not even be remedied by making the aircraft larger than it already was, which was roughly the size of a baseball diamond. Consequently, Johnson told the Secretary of the Air Force “I’m building you a dog” [2, p. 177] and voluntarily pulled out of the project in 1957.

A key byproduct of Suntan, though, was that the significant challenges associated with taking liquid hydrogen from a laboratory curiosity and turning it into a practical propellant that could be produced and stored in large quantities had been solved. In addition, Pratt & Whitney, a division of United Aircraft Corp., had gained significant experience in operating liquid hydrogen engines, although turbojets rather than rockets. When interest in developing high-energy rocket engines surfaced, this experience was key to the development of hydrogen/oxygen engines. (One hurdle was that, since Suntan was so highly classified, rocket developers were not initially aware of the progress that had been made.) Pratt & Whitney’s work on the modified J-57 and Model 304 turbojet engines provided a good background for their subsequent development of the RL10 hydrogen/oxygen rocket engine that was used in the Saturn I launch vehicle as well as the Centaur.

Centaur vs. Saturn

The Saturn I and the Centaur were developed at roughly the same time and, although the products of two very different rocket design groups, interacted quite significantly. The Saturn I came from the Army Ballistic Missile Agency at Redstone Arsenal—later becoming NASA Marshall Space Flight Center—in Huntsville, Alabama, while the Centaur was produced by the Convair Division of General Dynamics in San Diego as an Air Force project. These two groups embodied contrasting approaches to launch vehicle design.

| A key byproduct of Suntan, though, was that the significant challenges associated with taking liquid hydrogen from a laboratory curiosity and turning it into a practical propellant that could be produced and stored in large quantities had been solved. |

The Saturn I was the first step by Wernher von Braun’s team in developing the Saturn rocket family that culminated in the Saturn V lunar launcher; the Saturn IB, a modified Saturn I with different upper stage, fell in between. The Saturn I first stage, the S-I, burning kerosene and liquid oxygen, was made up of grouped, stretched tankage from their earlier Redstone and Jupiter rockets: it was sometimes jokingly referred to as “Cluster’s Last Stand” [3, p. 80]. This approach made possible rapid development but did not lend itself to structural mass efficiency. The Saturn I second stage, the S-IV, burned high-energy propellants: it was powered by six Pratt & Whitney RL10 hydrogen/oxygen engines. It had been recognized by this point that, as stated by a Douglas Aircraft Co. engineer [3, p. 162]: “The combination of hydrogen and oxygen for propellants made the moon shot feasible. Its use in upper stages results in a significant increase in performance over the propellant combinations of oxygen and kerosene then in use in first-stage boosters”.

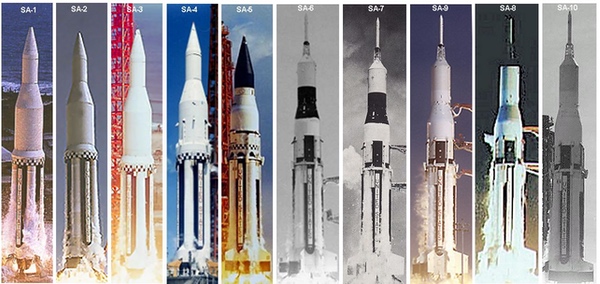

Saturn I test flight configurations. (credit: NASA) |

By contrast, an underlying goal in the design of the Centaur, powered by two RL10s, was structural efficiency. It was developed by the German-American engineer Krafft Ehricke to be a second stage matched in size, mass, and design philosophy to the Atlas rocket that was designed, also at Convair, by the Belgian-American engineer Karel “Charlie” Bossart. Both used the pressurized stainless steel structure that was pioneered for the Atlas: this extremely lightweight structure did away with strengthening stringers, propellant tanks internal to the rocket skin, and so on, and gained its stiffness from internal pressurization. To protect the structure from corrosion in the humid, salty air of Cape Canaveral, it was sprayed with the 40th iteration of a “water displacement” material that was made up of various hydrocarbons: this was later sold commercially as WD-40 [4, p. 143].

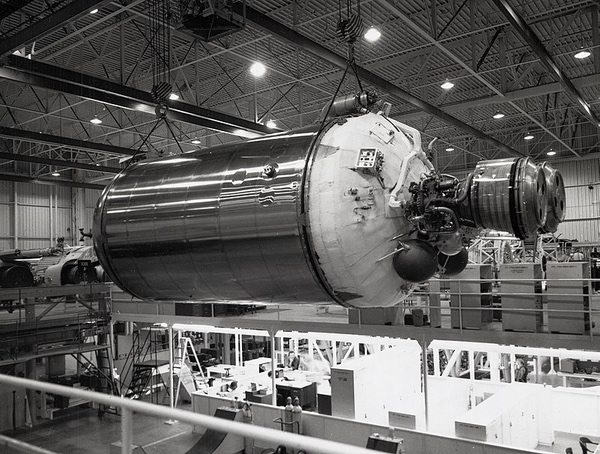

Centaur stage during assembly, 1962. (credit: NASA) |

If the pressure inside an Atlas were lost, it could crumple under its own weight: this occurred on the launch pad several times over the years. This engendered a certain amount of friction with von Braun’s team with their very different structural design philosophy: Bossart in a 1974 interview described the structure of Saturn rockets as being “built like the Brooklyn Bridge” [4, p. 169]. An example of these disagreements took place in 1961, when key members of von Braun’s team visited Convair. Willie Mrazek, von Braun’s chief of structures, got into a disagreement with Bossart, which led to them going over to a discarded Atlas tank that was used for testing. Bossart handed Mrazek a heavy rubber-coated lead mallet and invited him to “whack” the Atlas, to see if he could damage it. As described in [4, pp. 169–170]:

Mrazek gave it a tap and checked to see if the metal was dented.

“No, Willie, belt it!”

He hit it harder, and Charlie urged, “Willie, stop fiddling around. Hit the damned thing!”

This time, Mrazek gave it a strong blow, and the hammer bounced off the stiff metal surface and flew out of his grip, knocking his glasses off and landing 15 feet away. Muttering German curses under his breath, he inspected the tank and still could not find any sign of a dent.

Another engineer who had a similar “hit the tank” experience was James Fletcher, who at the time worked at Ramo-Wooldridge and later went on to serve twice as NASA administrator. He “thought he might do more damage by hitting the tank with a glancing blow, but instead he sprained his wrist” [4, p. 132].

Wernher von Braun, Karel Bossart, and Krafft Ehricke. (credit: NASA) |

Krafft Ehricke had worked at Peenemunde from 1942 to 1944 under von Braun, after serving in Panzers and being wounded twice. Although he credited his transfer to Peenemunde for saving his life, he did not really see eye-to-eye with von Braun, at least partially because Ehricke was enthusiastic about the use of hydrogen as a fuel and von Braun was deeply skeptical. Even so, Ehricke rejoined von Braun under Operation Paperclip, first at Fort Bliss, Texas, from 1947 to 1950, then in Huntsville from 1950 to 1952. He then left to work at Bell Aircraft in 1952 to 1954 and joined Convair in 1954. There he initiated the project to develop the Centaur as a high-energy upper stage sized to turn the Atlas into a highly capable space launcher, although it has been said that he was stronger as a visionary than as a manager [5, p. 380]. Centaur was initially an Air Force project but was transferred to NASA when it was created in 1959. Huntsville (i.e. NASA Marshall) was put in charge, which was not a recipe for success given von Braun’s resistance to the use of pressurized tanks and liquid hydrogen. In fact, in February 1962, after further Centaur delays caused by bad wiring, von Braun wrote in a note to Kurt Debus: “I’m about ready to suggest to blow up the whole darn project.” [5, p. 380].

Effects of Centaur delays on planetary missions

Meanwhile, the problems encountered in the development of the Centaur were having severe effects on planning for interplanetary missions. NASA Headquarters and the Jet Propulsion Laboratory (JPL) began in early 1960 mapping out what became the Mariner series of spacecraft to explore Venus, Mars, and Mercury. Assuming that the Atlas-Centaur would be ready in time, this plan started with a large (885-kilogram) “Mariner B” spacecraft performing a Venus flyby in 1962 [6, p. 34]. Unfortunately, though, several explosions of Centaurs in ground tests in 1960 and early 1961 made clear that the proposed timeline was not going to be possible. In addition, the payload capability of the early Atlas-Centaurs was found to be lower than previously predicted.

| In February 1962, after further Centaur delays caused by bad wiring, von Braun wrote in a note to Kurt Debus: “I’m about ready to suggest to blow up the whole darn project.” |

Consequently, the 1962 Venus flyby was revised over the course of only 11 months [6, p. 40] to use a lighter (204-kilogram) spacecraft launched on the smaller Atlas-Agena launch vehicle. Since this spacecraft was a stripped-down development of the 367-kilogram lunar Rangers that were also launched on Atlas-Agenas, with mass reduced to allow an interplanetary mission, it was termed internally the “Mariner-R” while, externally, it was called Mariner 2. It performed the first successful flyby of another planet in December 1962, determining the extremely high temperature of the surface of Venus. The subsequent Mariner 4 and 5 (“Mariner C”) spacecraft were also launched on Atlas-Agenas until the Atlas-Centaur was ready for use from Mariner 6 onwards.

The Agena upper stage was originally developed as a key component of the CORONA reconnaissance satellite [7, p. 34]. It was considerably smaller than the Centaur, and with lower performance: it had a diameter of 1.5 meters (5 feet) rather than 3 meters (10 feet), a propellant mass less than half that of the Centaur, and a specific impulse only about two thirds the Centaur value as a result of its use of hypergolic propellants (hydrazine and nitric acid) rather than hydrogen/oxygen. Consequently, the performance of the Atlas-Agena for planetary missions was much lower than that of the Atlas-Centaur.

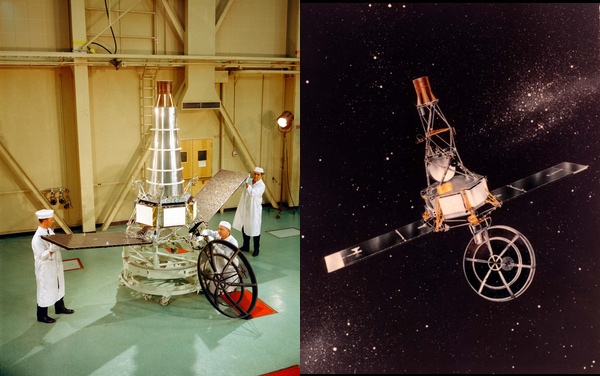

Ranger 7 lunar probe and Mariner 2 Venus probe (“Mariner-R”), both launched by Atlas-Agena. (credit: NASA) |

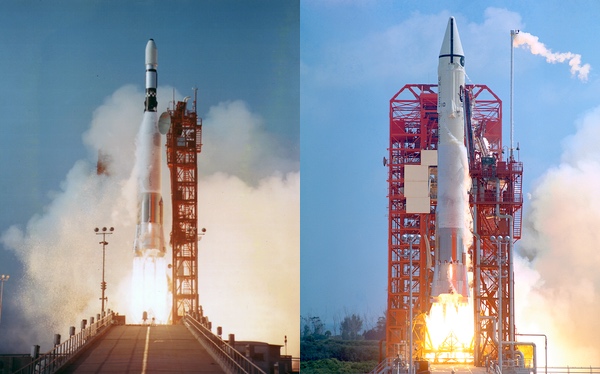

Atlas-Agena (left) and Atlas-Centaur (right). Note the different sizes of the two upper stages relative to the Atlas. (Credit: NASA) |

In response to the Centaur development delays, Marshall in September 1962 proposed replacing the Atlas-Centaur for planetary missions with a Saturn I equipped with an Agena third stage [6, p. 48]. At this point, it appeared likely that the Saturn I would make it to orbit before the Atlas-Centaur, so this replacement was expected to save time. Original plans for the Saturn I had included using a slightly modified version of the Centaur [3, p. 159] as a third stage, termed the S-V, although this was only ever flown in dummy form, with water-filled tanks, on the first four suborbital launches. The proposal to add an Agena was therefore somewhat in keeping with the original plans. It appeared acceptable to JPL, but NASA Headquarters vetoed it. Instead, Centaur management was transferred to NASA Lewis Research Center, the director of which was the hydrogen/oxygen proponent Abe Silverstein.

It is interesting to note that, while a Saturn I-Agena would have had a payload capability roughly equivalent to that of the Atlas-Centaur for planetary missions, it would have had a launch mass nearly four times as great. This inefficiency is a reflection of its much less capable upper stage. A modern parallel exists in the Space Launch System (SLS): its current upper stage, the Interim Cryogenic Propulsion Stage, is essentially a Delta IV five-meter-diameter upper stage, and is smaller than optimal for a launch vehicle of this size. It is to be replaced by the Exploration Upper Stage, with nearly ten times the propellant mass, which will increase the trans-lunar injection payload capability by about 40%.

Centaur success

The transfer of Centaur management to NASA Lewis was a key turning point in the development of the Centaur. The first Atlas-Centaur test launch, on May 8, 1962, was a failure, but the first under Lewis management, carrying no payload, succeeded on November 27, 1963. Interestingly, the Atlas-Centaur ended up beating the Saturn I to orbit: this only took place on January 29, 1964. Several other Atlas-Centaur failures followed, but its first key operational use, to launch the seven Surveyor lunar landers in 1966 to 1968, was entirely successful.

| The transfer of Centaur management to NASA Lewis was a key turning point in the development of the Centaur. |

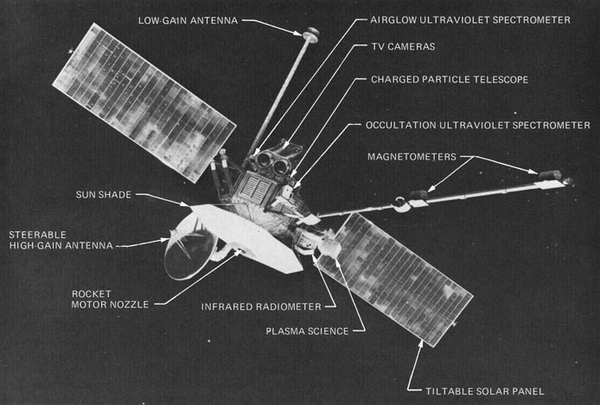

Following this, the Atlas-Centaur became increasingly used for communication satellites (e.g. Intelsat 4s), astronomy satellites (e.g. OAO-2 and HEAOs 1-3), and finally Mariners 6 through 10. By way of a performance comparison, the Mariner 2 spacecraft to Venus, launched on an Atlas-Agena, had a mass of only 204 kilograms; Mariner 10, a mission to Venus and then Mercury that was launched on an Atlas-Centaur, had a mass of 503 kilograms. Pioneer 10 to Jupiter and Pioneer 11 to Jupiter and then Saturn were also launched on Atlas-Centaurs, as were the Pioneer Venus Orbiter and Multiprobe.

The Centaur was then adapted for use on other launch vehicles, for instance the Titan IIIEs used to launch Vikings 1 and 2 and Voyagers 1 and 2. Convair (by then General Dynamics) designed a stretched Centaur to launch spacecraft for the proposed Grand Tour of the outer planets [8, pp. 31-33]: the proposed design is somewhat reminiscent of the Centaur G-Prime version that was at one point planned to launch the Galileo Jupiter probe. There was also a proposal for a Centaur space tug to supplement the Space Shuttle [8, pp. 33-35].

Mariner 10 Venus probe launched by Atlas-Centaur. (Credit: NASA) |

A total of 271 Centaurs have been launched to date, with the latest Centaur V version for the Vulcan containing nearly four times the propellant mass of the original Centaur. And, unlike the Atlas, which changed to a design with stiffeners for the Atlas V version, the Centaur V still has pressurized tanks.

References

- Liquid Hydrogen as a Propulsion Fuel, 1945-1959, J.L. Sloop, The NASA History Series, SP-4404, 1978.

- Skunk Works: A Personal Memoir of my Years at Lockheed, B.R. Rich and L. Janos, Little, Brown and Company, 1994.

- Stages to Saturn: A Technological History of the Apollo/Saturn Launch Vehicles, R.E. Bilstein, The NASA History Series, SP-4206, 1980.

- Bossart: America’s Forgotten Rocket Scientist, D.P. Mitchell, Mitchell Publishing, 2016.

- Von Braun: Dreamer of Space, Engineer of War, M.J. Neufeld, Vintage Books, 2007.

- On Mars: Exploration of the Red Planet, 1958-1978, E.C. Ezell and L.N. Ezell, The NASA History Series, SP-4212, 1984.

- Eye in the Sky: The Story of the Corona Spy Satellites, ed. D.A. Day, J.M. Logsdon and B. Latell, Smithsonian Institution, 1998.

- Centaur, General Dynamics Convair Aerospace Division booklet, Jan. 1971.

Note: we are now moderating comments. There will be a delay in posting comments and no guarantee that all submitted comments will be posted.