The case for smaller launch vehicles in human space exploration (part 2)by Grant Bonin

|

| While a failing launch system may be shut down for investigation, a program that uses not just multiple launches, but also multiple types of launchers, needn’t suffer the same fate. |

For high-fidelity (i.e. highly dependable) systems, overall reliability can be approximated quite reasonably as the product of all the individual reliabilities of each mission critical, non-redundant subsystem. So, for example, if a launch vehicle has 50 components that are non-redundant, each of which has a reliability of 99.95%, then the launch vehicle could be estimated as being approximately (99.95%)50 ~ 97.5% reliable. We can expect (indeed, we would pretty much require) that the launch vehicles used in piloted lunar or Mars expeditions have a success probability of at least 98%, but in a multiple-launch scenario, we can’t just speak in terms of individual launch reliabilities alone. Each booster used in the sort of mission plan described earlier (see part one) is itself a component of an overall system—the system injecting a spacecraft onto a Mars-bound trajectory—so each individual booster has to be considered as a component rather than a singular entity. So for a payload requiring six launches to assemble in total, with each launch having a success rate of about 98%, the risk of losing a single booster is only about 2%: however, the risk of losing a mission component from launch failure would be higher: approximately (1 - 0.986) ~ 0.11, or an 11% risk of failure. And that sounds pretty bad.

Of course, the most obvious way to get around this issue is to make your launch technology more reliable. A difficult prospect to be sure, yet one that NASA is currently attempting to with their shuttle-derived Crew Launch Vehicle (CLV): based on a single space shuttle solid rocket booster, the current design for the CLV will, as projected by NASA, have a failure probability on the order of only 1 in every 2000 launches. If NASA can pull it off, it will represent an extraordinary achievement in launch technology, and developing the CLV will still require far less from NASA than its proposed heavy-lift vehicle.

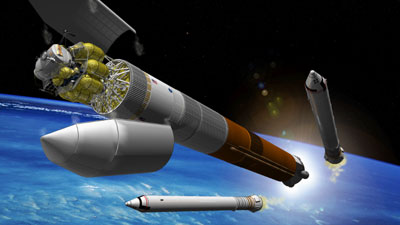

However, perhaps the issue of failure in multi-launch mission designs is not, in and of itself, as critical an issue as detractors contend to begin with. In fact, in a political context, breaking up a mission into multiple components may actually be regarded as a great strength: while multiple launches certainly increase the likelihood of losing a component because of launch failure, any such loss would actually represent only a small percentage of the mission, and so, with the exception of the booster delivering the crew to orbit (which would only be one out of every 12 launches in our reference mission design), failure in any single launch could be offset by delivering a replacement component to orbit. While a failing launch system may be shut down for investigation, a program that uses not just multiple launches, but also multiple types of launchers, needn’t suffer the same fate. On the other hand, a program of lunar or Mars exploration predicated on the use of a single, dedicated heavy-lift booster may find itself indefinitely delayed—or even permanently grounded—as a result of only one failed launch, which is all but certain to happen at some point during any vehicle’s operation. If the program is based on deploying entire missions with a single booster, then losing that booster would mean losing the crew, the spacecraft, the mission; and any chance of flying again any time in the near future.

Literally and figuratively, a heavy-lift booster keeps all the mission eggs in one basket, while launch failure in a program using smaller boosters is, in short, less likely to be either mission or program critical: an important level of flexibility for a program of manned spaceflight to have, and something that “all up” launch vehicles simply can’t offer.

Additional risk factors, such as propulsion stage failure and orbital debris impact are discussed at length in reference [2], and do not, in spite of what HLLV advocates claim, represent significant risk factors to this sort of mission design. While the reference mission plan discussed as an example was based on Mars Direct, a number of alternative Mars mission architectures as well as lunar ones can be accomplished using smaller launch vehicles and orbital assembly by similar methods.

Getting back to the bottom line

Consider again our proposed program of human Mars expeditions, which would require launching 50 tonnes of payload to the Red Planet every year to support continuing human exploration. We’re now in a position to take a look at the specific economics of flying this sort of mission, first using heavy lift boosters, and then using candidate medium-lift vehicles.

| Since the medium-lift booster will require far fewer employees and enjoy a significantly higher launch rate using less maintenance-intensive facilities, the number of man-hours per flight will be substantially less than for the HLLV. |

Let’s assume we have a heavy-lift launch vehicle that’s capable of throwing approximately 50 tonnes trans-Mars in a single launch (a bit more optimistic than the shuttle-derived launcher which NASA currently proposes developing). Let’s then assumed the HLLV requires approximately $10 billion to develop, in line with what NASA currently estimates. Since our reference mission will require an average of one spacecraft launched to Mars per year for a continuing series of expeditions, our heavy-lift vehicle will fly an average of once per year (in reality, twice every two years), so over a program run of, say, 10 years in total, the amortized cost of the HLLV development will be $10,000,000,000/(1x10) = $1 billion per flight, which translates to approximately $97,000 per kilogram sent to Mars in terms of capital investment alone.

Now consider launching the mission using medium-lift launch vehicles. Let’s assume that production and launch facilities for the smaller booster only cost $1 billion to develop (an order of magnitude less than the heavy-lifter, corresponding to a smaller, simpler vehicle); then because six launches would be required per Mars-bound spacecraft, with an average of one such spacecraft per year, the 10-year amortized cost of development would be $1,000,000,000/(6x10) = $16.7 million per flight, or approximately $3,300 per kilogram sent to Mars. (This, by the way, assumes that the medium-lift vehicle being used would have to be developed from scratch, when in fact there already exist a number of launch systems that can do the job, and more on the way.)

Some advocates of small launch systems go much further than advocating 20-tonne to orbit boosters. Imagine, if you will, that instead of using our Delta 4s or Atlas 5s, we were instead using a launch vehicle that could only deliver five tonnes to orbit. In order to deploy our reference Mars-bound payload of 50 tonnes (and dispatch it to the Red Planet), about 35–40 launches per year of the smaller vehicle would be required. So, assuming that such a small vehicle only cost about $200 million to develop (indeed, we’re closer to SpaceShipOne than the Atlas now), then over a decade of operation assembling Mars missions (making reasonable assumptions for recurring expenses) the cost per kilogram sent to Mars could drop to an amount on the order of $2,200.

These numbers are impressive, but only really speak to capital investment: what about recurring costs? Well, because the medium-lift vehicle team will be producing at least six launchers per year, the cost per unit can be expected to drop somewhat in response to increased production rates: not by much of course, since we’re still only talking about a half dozen units, but it’s still an advantage which the heavy-lift team won’t experience. But much more significant than the drop in production cost will be the savings achieved in terms of labor costs: since the medium-lift booster will require far fewer employees and enjoy a significantly higher launch rate using less maintenance-intensive facilities, the number of man-hours per flight will be substantially less than for the HLLV. The big booster, while having to employ a veritable standing army of support staff, will only be used about once a year on average (actually, twice every two years), significantly increasing the man-hours required per launch and keeping the amount of practice its employees actually get in launching rockets to a minimum. Conversely, the much smaller crew of the medium-lift booster will get to do their jobs far more often—a better way of keeping employees sharp—and will enjoy far better economy per man-hour.