Aerospaceplanes and space solar powerby Mike Snead

|

| Without the ability to practically reach space with high flight rates and without substantial in-space operational capabilities, SBSP will remain a “wouldn’t it be great” proposition. |

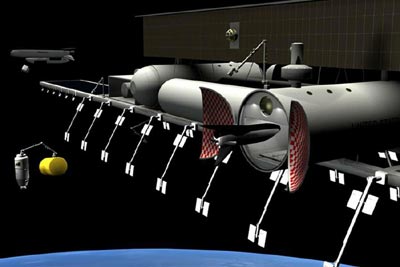

Supplying a substantial percentage of America’s future electrical power supply from space using SBSP systems can only be expressed as a giant leap forward in space operations. Each of the hundreds of solar power satellites needed would require 10,000–20,000 tons of components transported to orbit, assembled in orbit, and then moved to geostationary orbit for operations. The scale of logistics operations required is substantially greater than what we have previously undertaken. Periodically, industrial operations experience revolutions in technology and operations. Deep sea oil exploration is an example. Within a couple decades, entirely new industrial operations can start and grow to significant levels of production. The same will happen with space industrialization when—not if—the right product or service is undertaken. SBSP may be the breakthrough product for leading the industrialization of space. This was our assumption in conducting the study. As the cost of oil approaches $100 a barrel, combined with the possibility of the world reaching peak oil production in the near future, this may turn out to be a valid assumption.

While most of the SBSP study efforts focused on the technology tip of the SBSP spear, the logistics breakout group focused on the shaft of the spear, to use a military logistics analogy. Without the ability to practically reach space with high flight rates and without substantial in-space operational capabilities, SBSP will remain a “wouldn’t it be great” proposition. The starting point was defining the logistics group’s purpose and assumptions. The purpose was to identify near-term technical concepts and an implementation strategy to provide American spacefaring enterprises with the needed robust, effective, and efficient space operational capabilities. Spacefaring enterprises include SBSP systems as well as space tourism, space exploration, space colonization, among others.

The assumptions used were:

- The development of an integrated spacefaring logistics infrastructure is part of a general national space strategy to establish mastery of operations in space and transform the United States into a true spacefaring nation. This will require, over several decades, national investment to strengthen and expand the nation’s aerospace industry and associated capabilities.

- While supporting the development, deployment, and operation of space-based solar power, the spacefaring logistics infrastructure will also be used by all American spacefaring enterprises.

- The infrastructure will be developed as a public-private partnership emphasizing competitive commercial products and services to provide assured national spacefaring logistics capabilities. Following the establishment of baseline capabilities, the commercial extension and expansion of these commercial spacefaring logistics capabilities will be encouraged.

- The central function of the integrated spacefaring logistics infrastructure is to transport, sustain, and service American space enterprises, both governmental and commercial, throughout the Earth-Moon system by 2030, and throughout the central solar system by 2050.

- The development and deployment of the spacefaring logistics infrastructure will be undertaken in phases. The time phasing of the development and deployment of the phases will be scheduled such that later phases “bootstrap” off of earlier phases.

- Emphasis will be placed on employing Technology Readiness Level 6–9 technologies to establish the initial operational capability of each phase and then to use pre-planned product improvements to introduce improved systems with more advanced technologies leading to improved safety, performance, and operability.

- Spacefaring operations, while emphasizing the practical use of robots, will necessarily remain a human activity to oversee the construction and operation of both the spacefaring logistics capabilities as well as SBSP systems. The spacefaring logistics infrastructure must provide suitably safe living, work, and transportation capabilities for humans traveling to, and living and working in, space.

- The development of both the spacefaring logistics infrastructure and the SBSP system will each be a major national undertaking. As such, these will have access to the necessary national resources for their development, production, and operation.

- While the initial elements of the SBSP satellites will be constructed entirely on the Earth or in space from terrestrially-supplied components, later SBSP satellites may be substantially constructed in space from extraterrestrial materials. Later phases of the spacefaring logistics infrastructure architecture will provide the capabilities to establish, maintain and support such future SBSP satellite construction methods.

- All new habitation and transportation systems used by humans will be fully-reusable and will be certified as airworthy through appropriate acceptance inspection and both ground and flight testing prior to placement into service.

- The start date for the full scale engineering development of the initial Phase 1 elements of the spacefaring logistics infrastructure is 2009 following preliminary organizational and engineering activities being undertaken in 2008.

Working from these assumptions, the spacefaring logistics infrastructure would be developed in the following eight phases extending through 2050. The study efforts focused on the first two phases.

- Establish routine access to low earth orbit (LEO).

- Establish LEO space logistics depots.

- Extend routine transportation throughout the Earth-Moon system.

- Support the initial space-based solar power satellite demonstrations, assembly, and operations in geostationary orbit (GEO).

- Support increased human and robotic resource survey missions to the Moon.

- Expand LEO capacity to support the increased assembly of SBSP satellites.

- Establish permanent lunar surface capabilities to support the extraction of resources.

- Establish Earth-Moon Lagrangian logistics capabilities to support in-space SBSP component manufacturing using extraterrestrial resources.

These assumptions address several points raised by Dinerman, including the need for fully-reusable space access and the use of TRL 6–9 technologies. Further clarification on these two points is needed.

While some argue that SBSP construction and operations can be undertaken with little or no direct human involvement—using robotic and self-assembly technologies—I do not share the optimism that these technologies will develop to the level of maturity to enable this to be undertaken in the early phases of SBSP construction and operation. I base this on the fact that no comparable terrestrial examples of the needed robotic operations exist today. Absence this confidence, I believe that substantial human activity in space will be needed to undertake SBSP or other comparable space industrial operations. This means that the logistics ability to transport large numbers of travelers to and from space with “aircraft-like” safety and operability will be required.

The use of the phrase “aircraft-like” to describe the needed future human transportation capability is intentional. I do not use the term “reusable launch vehicle” or RLV because the design and operations heritage of expendable launch vehicles is not the approach that will lead to the needed level of passenger safety and operability required for successful industrial operations in space. The better model is taken from aircraft. However, the use of the term “aircraft-like,” or “aerospaceplane” to name the reusable space access system, does not relate to the physical design of the system—such as an expectation for horizontal takeoff on a runway. Rather, it relates to the aircraft systems engineering principles and practices that will be used to design, develop, produce, test, operate, and maintain the new systems to achieve “aircraft-like” levels of safety and operability.

| I do not use the term “reusable launch vehicle” or RLV because the design and operations heritage of expendable launch vehicles is not the approach that will lead to the needed level of passenger safety and operability required for successful industrial operations in space. The better model is taken from aircraft. |

The need for full reusability comes from the fact that the primary objective of flight system design is to achieve airworthiness. It is a characteristic that will be needed by aerospaceplanes (and spaceships for in-space transportation) to enable the level of spaceflight operations necessary to support space industrialization. Each and every production aircraft is demonstrated, through ground and flight acceptance testing, to be airworthy before it is placed into operation. Only fully-reusable flight systems can meet this standard because the airworthiness of each production expendable component cannot be demonstrated without using up its life. When one thinks about it, every terrestrial human transportation system meets this reusability acceptance test standard.

The expectation that near-term aerospaceplanes will be two-stage and rocket-powered comes from an assessment of the maturity of the technologies required by such flight systems. One approach to assessing the maturity of the technologies is to use the NASA-defined Technology Readiness Level (TRL) scale. A TRL of 1 corresponds to a new idea just starting to be developed while a TRL of 9 corresponds to a subsystem in routine operation. A TRL of 6 reflects a technology that is emerging from laboratory development and is judged, by the development engineers, to be ready for incorporation into the detailed design of a new operational system. For a new near-term system, all enabling technologies would need to have a TRL of at least 6. Practically, most will be at the 8 or 9 level if the performance, schedule, and cost risks of the program are to be considered acceptable. This is the case for a near-term, two-stage aerospaceplane such as the one described in the SBSP report’s Appendix D and in the supporting fact sheets.

The fact that such a two-stage aerospaceplane is not under active development today by a major American aerospace company is often taken as a sign that further basic technology development (TRL 3–5) is needed. Dinerman follows this line of thinking in his essay. Several years ago when I was presenting concepts for an integrated spacefaring logistics infrastructure to a major American aerospace company’s reusable space access technology development team, I used an illustration of a two-stage, rocket-powered aerospaceplane. The team’s immediate response was questioning why, in discussing a future infrastructure, would I use an illustration of something that could have been done for the last 20 years. My response was, as I recall, that was exactly the point I was attempting to make—that this is something that can be undertaken now.

The Generation 1 Aerospaceplane, included in the set of example concepts discussed in the SBSP report’s Appendix D, illustrates what many believe the American aerospace industry is now capable of developing. If we were to start in 2009, then the new aerospaceplanes could become operational by 2016–2018. Will some further technology research be required? Yes, to solve specific application problems as the TRL 6 technologies are brought to the TRL 9 level. This always happens with a new design, especially first-generation systems. However, we are at the point where further basic TRL 3–5 research is not needed for a first-generation aerospaceplane developed for routine passenger and cargo transport to LEO. If we are to rapidly proceed with building the infrastructure needed to support SBSP and other space industrial activities, it is very important that we avoid the trap of unnecessary requirements and unneeded technology insertion. These are the primary reasons why achievable two-stage aerospaceplanes have not been pursued in the last quarter-century.

If one accepts that the needed technologies for near-term aerospaceplanes are sufficiently mature to start their development, the final perceived obstacle is funding. Intentionally I have been discussing spacefaring logistics infrastructure. Building and operating infrastructure—the critical backbone of modern civilization—is typically undertaken through public-private partnerships and some form of government-backed funding. Quite often new infrastructure is built to provide updated and expanded operational capabilities. The old two-lane bridge is replaced by a more modern four- or six-lane bridge that requires less maintenance and upkeep. We can apply this line of thinking to building the needed aerospaceplanes where their development becomes the starting point for building the spacefaring logistics infrastructure.

| Building and operating infrastructure—the critical backbone of modern civilization—is typically undertaken through public-private partnerships and some form of government-backed funding. We can apply this line of thinking to building the needed aerospaceplanes where their development becomes the starting point for building the spacefaring logistics infrastructure. |

Each year the federal government spends $5–6 billion on space access, most of which is spent for human space access. If America is to remain a leader in space, then human space access must be maintained. Looking beyond the needs of the Vision for Space Exploration, if we are to build the SBSP system or undertake any significant expansion of human space operations, fully-reusable aerospaceplanes are needed. Infrastructure building is typically debt-financed and then the debt is retired when the new infrastructure becomes operational. Assuming that the operational life of the new aerospaceplanes will be 25 years, continuing the current $5–6 billion expenditures for these 25 years would provide $125–150 billion to pay for the development and production of the aerospaceplanes, the interest on the debt, and the recurring operational costs to provide the government with passenger and cargo transport to LEO.

This level of funding will enable two types of near-term aerospaceplanes to be built. This is needed to provide America with assured space access capabilities. Three or four operational systems of each type will be built for a total of six or eight systems in the new aerospaceplane fleet. With a system flight rate of every four weeks, the fleet would have an annual flight capacity of 70 to 90 missions. With a system flight rate of every two weeks—consistent with a fully mature system—the annual flight capacity will grow to 140 to 180 missions. Of these, 20 missions would be used by the government and the remainder used by other customers and used to support the construction and operations of the in-space elements of the infrastructure.

The NSSO summer study on SBSP provided a forum to discuss the spacefaring logistics infrastructure needs of a space industrial nation. What we reported was that robust, efficient, and effective spacefaring logistics infrastructure capabilities can now be established. America now has the technologies to do this. Unlike when SBSP was first considered in the late 1970’s, the logistical ability to build and operate a constellation of SBSP satellites is now achievable. Also, while the initial elements of this infrastructure are being completed, the final technology maturation of the SBSP satellites can be completed. With this approach, the first SBSP satellite construction could start about 2025.

At $100 per barrel, America’s annual cost of imported oil is about $440 billion per year. During the six to eight years required to bring the aerospaceplanes into operation, America will send to foreign countries $2.6–3.5 trillion for imported oil. Every year that we fail to act to substantially decrease our need for imported energy is $440 billion spent unnecessarily in the future. I believe the American aerospace industry is capable of building the spacefaring logistics infrastructure needed to support the development, deployment, and operation of the SBSP system that can start to address this problem. It is a starting point for the American industrialization of space and our transformation into a true spacefaring nation.

Additional information on the logistics concepts discussed in the SBSP report is available at: http://mikesnead.net/resources-spacefaring.htm. The logistics summary (Appendix D) is available along with 16 supporting fact sheets. For further information on designing “aircraft-like” reusable space access systems design, see “Achieving Near-Term, Aircraft-Like Reusable Space Access.” For information on the conceptual design analysis used to define the Generation 1 Aerospaceplane, see “Cost Estimates of Near-Term, Fully-Reusable Space Access Systems.”