How an intermodal COTS system can accelerate commercial servicing in GEOby Andrew E. Turner and Gerrit van Ommering

|

| The Container concept was developed by CSI as an efficient way of delivering cargo similar to the way terrestrial intermodal logistics work. The idea is to keep containers as simple as possible, with standardized interfaces so that they can be moved by transporters specialized for each leg of the trip. |

Containers accommodate both internal and external ISS cargo. Internal cargo is stowed in the pressurized section and is removed by the astronauts through a hatch, opened after the Container is berthed to the ISS. External cargo is attached to an un-pressurized section and is removed by the ISS manipulator arm. The low cost of each Container makes occasional launch failures tolerable, compared to launch or return failures of competing systems that rely on returning and reflying an expensive core vehicle, or that are dependent on a specific LV. Additional Containers will be in the production line and can be quickly orbited on different launchers than the one that failed.

The intermodal Container approach inherently minimizes operational impact on the ISS. Astronauts will have immediate access to all cargo via the Container’s central aisle, but they can also leave cargo in place until it is needed. The Container can stay at the ISS for many months, allowing the crew to use it as an extended storage container, and only needs to leave when the next Container is ready for delivery. This is an advantage over reusable delivery spacecraft, which require that the ISS crew to quickly unload all cargo so the vehicle can return to Earth by a deadline to be refurbished and prepared for the next launch.

A key feature of the SS/L COTS concept is that the Tug is fully reusable and will deliver the cost benefits of reusability where it really counts. The Tug, with its sensors, actuators, docking gear, manipulators, avionics, and control capabilities, is launched just once and remains in its mission orbit throughout its ten-year lifetime, where it is never subjected to the risk and stress of repeated reentry and relaunch. This eliminates the recurring cost of subsystem checkout, refurbishment, and recertification, required for concepts that must repeatedly survive the stress of launch and reentry.

Most of the Tug’s subsystems are derived from SS/L’s flexible 1300 model spacecraft, 48 of which are currently providing service in orbit with four more ready for launch and 14 under construction. It can carry a 3,800-kilogram propellant load, providing a huge propulsive capability that supports many ISS delivery and Container disposal missions. Most of the special equipment supporting ISS proximity operations is based on MacDonald, Dettwiler and Associates’s (MDA’s) flight subsystems on XSS-11, Orbital Express, and HTV, and manipulator arms on ISS and STS. The Tug will be periodically refueled by transferring propellants from specially-launched tanker modules, as demonstrated on Orbital Express.

SS/L’s highly adaptable, high capacity 1300 model spacecraft bus - the basis for the COTS Space Tug. (credit: Space Systems/Loral) |

The SS/L COTS combination of high cargo capacity per launch, low-cost standardized containers, and highly-reusable Space Tug economics will provide attractive cargo delivery cost savings.

| As Clayton Christensen pointed out in The Innovator’s Dilemma, a disruptive capability such as GEO servicing must develop first in a protected niche where it can prove itself and become accepted in the mainstream. |

SS/L and CSI have assembled a team that has all the direct and relevant ISS experience needed to safely and reliably implement this system. MDA, already mentioned above, is just one example. SS/L itself produces batteries and power electronics that process all primary power for the ISS. Other team members—Oceaneering Space Systems, Odyssey Space Research, ARES Corporation, and Paragon—are ISS mainstays in logistics, visiting vehicle operations, safety and mission assurance, and crew interfaces and training. United Launch Alliance, Applied Aerospace Structures, and NASA Ames Research Center round out the team.

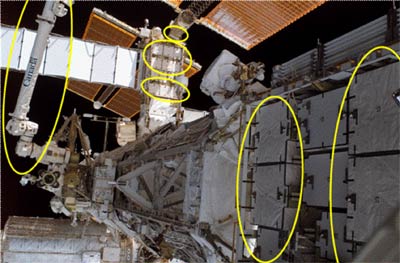

Just some of the key hardware that SS/L and MDA have already provided for the ISS. (credit: Space Systems/Loral) |

SS/L’s particular approach to COTS could provide a path to servicing commercial spacecraft in geosynchronous Earth orbit (GEO). Satellites in GEO are the biggest moneymakers in space, generating billions of dollars in revenue annually by providing communications between fixed sites, direct-to-home TV, digital satellite radio, Internet access, and mobile telephone services. While they are already designed for 15-year missions, GEO satellites could generate significant incremental revenue if they could be serviced, permitting them to last longer or carry more payload for a given launch mass. Servicing in GEO could include refueling, assisting with station keeping, rapid repositioning for backup or opening new markets, and end-of-life removal to the graveyard orbit. A demonstrated and operational spacecraft like the COTS Tug could readily provide these GEO services.

However, the magnitude of the incremental revenue may not easily justify making the significant investment required to develop GEO servicing from scratch. COTS, on the other hand, responds to a near-term need and an existing cargo delivery market and therefore clearly justifies the investment in developing the Tug and associated infrastructure. Once development and demonstration of a Tug with refueling capability is accomplished under COTS, it will dramatically lower the risk and cost barriers to fielding a capability for GEO servicing. An intermodal ISS cargo solution therefore clearly has great potential for broader commercial applications in space. The new GEO servicing market in turn will strengthen the company providing ISS cargo delivery services, assuring that these services will remain available at attractive prices.

As Clayton Christensen pointed out in The Innovator’s Dilemma, a disruptive capability such as GEO servicing must develop first in a protected niche where it can prove itself and become accepted in the mainstream. Intermodal standardized containers and refuelable space tugs derived from space-proven hardware are disruptive capabilities that will produce new commercial industries and services in space. With COTS as the first step, we may well see satellite servicing creating billions of dollars worth of new business in GEO and other orbits in the near future.