Ares evolutionby Scott “Doc” Horowitz

|

| Simply put, the Crew Office wanted the safest, simplest possible crew launch system that was sufficiently robust to survive a reasonable degree of unknown failure scenarios. |

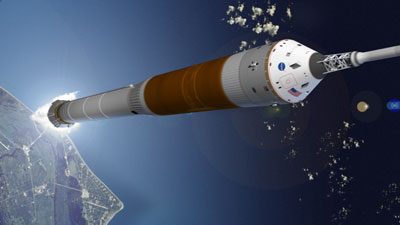

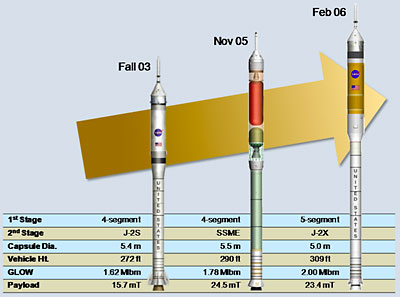

The initial version of the launch vehicle that met these requirements was a two-stage vehicle with the proven four segment booster from the Shuttle as the first stage and a single J-2S powered Liquid Oxygen (LOX)/Hydrogen upper stage (see Figure 1). This launch vehicle provides sufficient capability to lift a 5.4-meter diameter capsule with a Launch Abort System (LAS) to low Earth orbit (LEO). The launch vehicle thrust-to-weight ratio (T/W) of both stages results in a trajectory that maximizes abort effectiveness.

The Exploration Systems Architecture Study (ESAS) architecture added a larger Service Module (SM) to the crew capsule based on architecture trades and replaced the J-2S with the SSME. Subsequent NASA studies adopted the five-segment/J-2X to improve overall architecture commonality and reduce life-cycle costs. Initially this launch vehicle was referred to as the Crew Launch Vehicle (CLV), or in some circles the “stick” because of its long, skinny configuration. The CLV configuration generated some concerns relative to the perceived hazards of having a solid booster as the first stage and the controllability of a long skinny vehicle.

Figure 1: Evolution of the Crew Launch Vehicle. (credit: NASA) |

To help address the safety and reliability issues, SAIC was commissioned to evaluate the potential hazards of the first stage solid and the overall reliability of the vehicle. The SAIC study (SAICNY05-04-1F) showed that a worst-case scenario of a catastrophic case burst of the first stage (extremely unlikely) would result in a maximum overpressure at the crew capsule of approzimately 1 psi. This overpressure is well within the design characteristics of the capsule. SAIC also conducted an initial Probabilistic Risk Assessment (PRA) evaluation of the reliability of the launch vehicle and estimated a launch vehicle failure rate (LOV) of 1 in 483 and a loss of crew rate (LOC) of 1 in 3,145 at the mean of the estimated uncertainty distribution. Recent NASA PRA estimates for the current configuration predict a LOC of approximately 1 in 2,500. This compares to the LOC for Shuttle of 1 in 88.

To help understand the controllability concerns of the relatively high length-to-diameter ratio (L/D), a number of aerodynamic analyses were conducted by industry and government showing that the CLV configuration was within the experience base of previously flown vehicles. However, as part of the input provided to NASA HQ, it was recommended in December of 2004 that a very early test flight be flown to demonstrate the following objectives:

- Basic aerodynamics of the vehicle (including roll movements)

- Controllability of the vehicle

- Separation dynamics between the first stage and upper stage

- Recoverability of the booster at the more severe recovery conditions for CLV

- Ability of the NASA/Industry team to develop and fly a new vehicle reliably in a short period of time

In 2003 an industry consortium of contractors involved in the Shuttle program (Boeing, Lockheed Martin, USA, ATK, and Rocketdyne) was evaluating various options as potential follow-on to Shuttle. This Shuttle-derived industry team was primarily interested in identifying ways to leverage the demonstrated Shuttle hardware heritage in future launch vehicles. One of the heavy-lift launch vehicles being evaluated was an adaptation of a heavy-lift launcher formulated as part of the Space Launch Initiative (SLI) studies conducted by JSC. This Shuttle Derived Heavy Lift Launch vehicle (SDHLV) consisted of two Shuttle solid rocket boosters, an External Tank (ET) diameter core stage that was powered by five Space Shuttle Main Engines (SSMEs), and a single SSME-powered upper stage.

The CLV and SDHLV were included in the launch vehicle trade space that was evaluated by NASA Headquarters shortly after President Bush announced the Vision for Space Exploration in January 2004. The Exploration System Architecture Study (ESAS) results were released in November 2005 and recommended an architecture using the CLV for transporting crew, and using the SDHLV for transporting the lunar lander and Earth Departure Stage (EDS). In the ESAS evaluation the SDHLV nomenclature was changed to Cargo Launch Vehicle (CaLV). The ESAS CLV configuration was a four-segment first stage and used an SSME on the second stage, which was the fastest to develop. The ESAS CaLV configuration used two five-segment Solid Rocket Boosters (SRBs), a stretched External Tank (ET) core with five SSMEs and a J-2 on the upper stage, which was also the Earth Departure Stage.

| Contrary to much of the misinformation being presented, the Ares I Program is not behind schedule or over budget. |

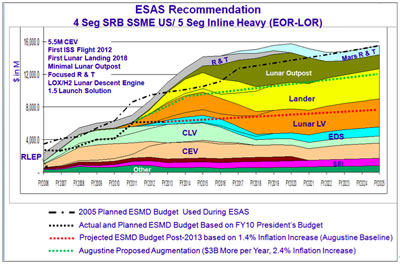

Initial projections based on ESAS were to have a launch of the CLV in 2010 and the first lunar landing in 2018. The ESAS recommendation was based on the budget profile shown in Figure 2. Since the Orion capsule would not have been ready to support a launch in 2010, and to reduce overall program cost, it was decided in Feb 2006 to change the CLV configuration to a five-segment booster first stage and a J-2X engine on the upper stage. This increased the synergy between CLV and CaLV, resulting in a total program cost savings of approximately $4 billion. This also resulted in a delay of the initial CLV launch to 2012. These projected launch dates were based upon the estimated budget profile from ESAS shown in Figure 2. This budget profile presupposed the Shuttle would finish its missions in 2010 and ISS would be supported only through 2015 (consistent with Presidential Directive). Over the years, the actual budget afforded NASA was substantially less than the initial projections (see Table 1). Due to reduced NASA budget requests from the administration and a full-year continuing resolution budget fiscal year 2007 and earmarks, the actual Constellation budget through fiscal year 2010 has been $12.6 billion less than projected by ESAS and will be $20.4 billion less by 2014. This budget shortfall has resulted in delaying the initial launch of the CLV with crew to 2015; further reductions in budget will extend this.

Figure 2: NASA space exploration budget projections from ESAS. |

The Augustine Report indicated that Constellation would need at least another $18 billion through fiscal year 2020 above the 2010 budget to meet program objectives, which is significantly less than the projected budget shortfall. The commonality in the solid booster and J-2X engine between the CLV and CaLV resulted in a reduced total development cost and accomplished the design, test, and evaluation of all of the major propulsion elements (5-seg, J-2X, LOX/H2 upper stage, RS-68) for the architecture earlier than scheduled. This overall synergy change was referred to as “Lunar Sooner.” Recognizing that the heavy lift CaLV is required for any missions beyond LEO and the development of the five-segment booster and J-2X was required for CaLV, the net result is the CLV can be developed for a marginal cost of about $2.7 billion over the cost of the developing the CaLV alone. The names of the vehicles were changed from CLV to Ares I and CaLV to Ares V.

In spite of the synergies of the Ares I and Ares V architectures, the delay of the initial launch of Ares I to 2015 will likely be compounded further by potential extensions to Shuttle flights and extending ISS deployment to 2020 or beyond. The Shuttle extension will cost at least $1 billion, and the ISS extension will cost about $2 billion a year, neither of which are currently in the NASA budget request. These unfunded Shuttle and ISS activities will have an even more dramatic effect on the development schedule for Ares V and Altair.

Table 1 (all values in billions of dollars)

| Fiscal Year | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | Totals |

|---|---|---|---|---|---|---|---|---|---|---|

| ESAS | 3.468 | 4.152 | 4.366 | 5.418 | 6.311 | 8.610 | 9.442 | 9.833 | 10.128 | 61.728 |

| Appropriated / Projected | 3.050 | 3.405 | 3.143 | 3.505 | 3.963 | 6.077 | 6.029 | 5.967 | 6.195 | 41.334 |

| Difference | -0.418 | -0.747 | -1.223 | -1.913 | -2.348 | -2.533 | -3.413 | -3.866 | -3.933 | -20.394 |

Contrary to much of the misinformation being presented, the Ares I Program is not behind schedule or over budget. With all of the constraints of a reduced budget, the program is meeting budget and schedule projections. The perceived schedule slip in Initial Operational Capability (IOC) from 2012 to 2015 has not been the result of programmatic or technical hurdles. The Ares Program has simply adapted to the funding afforded by the Administration and Congress, which is consistent with the “go as you pay” philosophy initially adopted by the Constellation Program from the very beginning.

Critics have also tried to discount the Ares I-X flight as a publicity stunt. Ares I-X was formulated in December 2004 to reduce program risk, evaluate technical issues (controllability, aerodynamics, etc.), and most importantly provide a “pathfinder” for NASA and its contractors to design, develop, test, and evaluate a new launch vehicle. The flight of Ares I-X not only accomplished those goals, it also was a testament that NASA is moving down the path with the right architecture to launch America into the next era of space exploration.

Postscript: The original concept for what is now Ares I (referred to here as the New Evolved Launch Vehicle) originated in the astronaut office at JSC in the fall of 2003. The following is an excerpt from the original NASA Form 1697 (Disclosure of Invention and New Technology) dated December 4, 2003, submitted to JSC legal:

The New Evolved Launch Vehicle maximizes the use of man-rated components and integrates them in a way to optimize performance and reduce risk. The New Evolved Launch Vehicle utilizes a Space Shuttle Solid Rocket Booster for the first stage and a LOX/H2 second stage utilizing the J2 engine developed for the Apollo program. Calculations show that this combination will deliver 30-40,000 pounds of payload to a 51.6 degree 150nm x 150nm orbit (a version using a 5-segment Solid Rocket Motor can deliver 40-45,000 pounds of payload). The trajectory for this Launch Vehicle provides a much more benign environment for abort scenarios. The major components are/were man-rated and have a much higher reliability than the components of the current Expendable Launch Vehicles being considered for Orbital Space Plane.