Brick by brick: a Lego spaceflight paradigmby Simon Vanden Bussche

|

| A basic tenet of systems engineering says that complexity is not defined by the number of elements of a system, but by the number of different elements and the number of different interactions of these elements. |

In the paper, the authors propose an alternative “commercially based” architecture, aimed in the first place at missions to the Moon. Going to the Moon also is the first aim of the NASA architecture put in place in previous years, commonly referred to as Constellation. This focus on the Moon is because both architectures are based the Vision for Space Exploration (VSE), an overarching strategy for the future of human spaceflight put together at NASA following the Columbia accident of 2003. The VSE provides an answer to the “why” of human spaceflight: we go to the Moon to learn how to create a sustainable human presence in space.3 The Constellation program was a first attempt at the “how”. The basic architecture of Constellation was created in the ‘Exploration Systems Architecture Study’ (ESAS) of 2005. Zegler et al. point out an important “choice” of this architecture:

The ESAS architecture has led to the demand for not one but two heavy lift boosters, two large upper stages, a large lunar descent vehicle, another unique Orion service module and a lunar ascent vehicle […]. These machines share minimal commonality and require multiple propellant combinations and four main engine types. Each requires a separate development program with attendant costs approaching $100 billion followed by a profusion of long term support contracts to support just a couple annual flights of each element.

A basic tenet of systems engineering says that complexity is not defined by the number of elements of a system, but by the number of different elements and the number of different interactions of these elements. This way, a hundred Lego bricks of three basic types, connected with a common interface, make for a much less complex system than 15 specialized plastic pieces, only to be put together in one specific way.

Additionally, the use of cost-plus contracting for all these different “bricks” effectively discourages cost-effective design or operations. Put bluntly, “cost-plus” means companies get paid what they spend designing the system (up to a limit, plus some profit margin), whatever time or budget overruns they encounter.4

These two problems with the ESAS architecture are the basic thoughts behind the alternative spaceflight architecture proposed in the ULA paper. The philosophy of their plan is using more launches of less specialized components to build a more flexible and affordable system:

The guiding philosophy that we have followed […] is to use the least number of distinct elements. This meant not only all-up vehicles, but the least number of main engines, avionics systems, fluids systems, ECLSS [Environmental Control and Life Support] systems, etc. By keeping the many elements as common as possible development is foreshortened and costs suppressed. Recognizing that each vehicle has unique functions it had to perform in addition to functions it shared with all other elements, flexibility and modularity had to be built in. […]

Of greatest importance was the ability to compete as many functions as possible in a marketplace. As much of the architecture as possible must be a commodity – something that many suppliers can provide. Without competition the suppliers to NASA would be in an eternal monopoly position – not a recipe for cost containment or innovation. This is the precise situation that is lamented today. The architecture needs to create a situation where many companies can make a business case close – a reliable, predictable demand with a calculable cash flow and good returns.

The goal thus is to use as few “bricks” as possible, and to create a reliable demand for them. These building blocks have a clear interface within the architecture, but allow for innovation in their own design. A strategy like this is a good systems engineering approach, but it also creates good conditions for private investment. To have a better look at what kind of building blocks are needed for such an approach, a system-wide overview is required:

The ESAS architecture and other similar ones such as Lunar Direct are focused so tightly on the lift capability that they almost wholly lose sight of the overall system operation and indeed of the costly overheads and real-world problems with supporting a huge number of vehicle configurations at low utilization rate into the indefinite future. These architectures are almost wholly intolerant of the inevitable changes that occur to their proposed payloads. The demand to lift another 3 tons of material from LEO to the lunar surface poses a huge, almost insurmountable obstacle. This means that performance is effectively limited by the architecture – it is incapable of adapting to changing needs. It is simply assumed that you have to live within the highly prescribed boundaries of the architecture and its many pieces. […]

Out of the ESAS design process came a number of very capable, but also very specialized pieces of hardware, that need to be put together in just the right way to make the architecture work. A failure in one of these means huge problems for all the rest. It is an architecture that might be made to work with time and money, but which basically excludes any form of flexibility. On the contrary, the architecture proposed in the paper tries to incorporate flexibility, modularity and affordability through its “three fundamental tenets”:

- The use of a common in-space propulsion stage

- An optimal separation of logistical and crew transport activities

- The use of propellant depots and equipment or cargo caches.

Of the mass that needs to be lifted to low Earth orbit (LEO) for a typical exploration mission, at least 70% consists of propellant for leaving Earth, performing the mission, and coming back. Because of its magnitude, moving propellant is far and away the most important element of an exploration mission. Importantly, propellant has a negligible intrinsic value compared to crew or cargo. This means that propellant is the optimal cargo for low-cost, strictly commercial launch operations on very regular and predictable schedules.

More specifically, Zegler et al. propose the use of simple depot variants based on an in-space propulsion stage. Goff et al. have described such a propellant depot,5 not requiring advanced zero boil-off techniques and zero-G fluid handling. Using propellant depots generally requires more launches, but this should not necessarily be a problem.

| Their architecture encourages the exploration of the Moon to be conducted not in single, disconnected missions, but in a continuous process, which builds orbital and surface resources year by year. |

In providing a predictable propellant demand, the authors claim, sustained government exploration efforts could jump-start a commercial transportation infrastructure throughout the nearby solar system, providing the equivalent of the establishment of airmail as a commodity activity for the fledgling aircraft and airline industries of the early 20th century. For this sustained and predictable business case closing cash flow, however, exploration efforts need a solid long-term plan. This is an essential condition for this “airmail” effect to realize.

Many other interesting points are made and scenarios worked out in detail in the paper. The authors conclude that their architecture encourages the exploration of the Moon to be conducted not in single, disconnected missions, but in a continuous process, which builds orbital and surface resources year by year. They explicitly state that in a plan like this, ULA is only one of the contenders for “making bricks”. Plus, their architecture has comforting overall margins. Even though the discussed plan is primarily focused on the exploration of the Moon, the flexibility of the approach allows using essentially the same building blocks for a whole range of conceivable space missions.

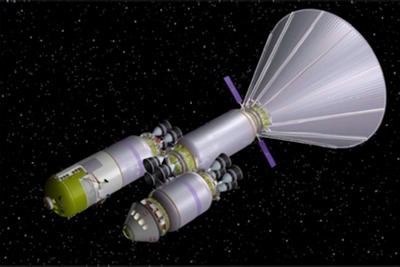

A manned transport, lunar lander and propellant depot, all based on the same in-space propulsion stage. Image from the Zegler et al. paper. |

A means to an end

The plans for NASA put forward by the Obama Administration have already been extensively described and discussed, more and less objectively. The following paragraphs attempt to look at the plans using the paper described above as a guide. The views expressed here are mine, and not necessarily the same as the views of the paper’s authors.

The fiscal year 2011 budget proposal has the potential to put a number of significant steps in the direction of an architecture like the one described above:

1. The cancellation of Constellation. As was mentioned by the Augustine Committee: “if Santa Claus brought us the system tomorrow, fully developed, and the budget didn’t change, our next action would have to be to cancel it” because of its enormous operational costs.

2. Most visibly: a number of demonstration missions that could prove certain vital technologies, including propellant depots.

3. Cost-plus contracting is avoided as much as possible, even for crew launch vehicles. This is a very important—and delicate—step. When NASA wants a competition for the different “bricks” of its architecture, it has to keep the competition fair. If one competitor gets a cost-plus contract to provide a “public option” building block, any business case is much harder to close for the other competitors, as mentioned recently by Boeing executives.6 These can be considered practical details, but they are essential for the future of the proposed plan.

As a personal note: this move to fully commercial procurement may seem risky. However, the risk this approach creates is mainly to the current NASA as a jobs program. For NASA as a space agency, and for the United States as a leader in human spaceflight and in technology in general, it holds many promises, mainly through stimulating innovation in the aerospace industry. As for crew safety, it should not be forgotten that safety will probably be the most important factor in the competition for delivering the “bricks”, even more than cost or performance. Competition between airlines was based on their safety record for many decades.

4. NASA has systematically ignored basic research and technology for many years, as illustrated by a recent NRC report7 on the dramatic state of its research labs. Reinstating this fundamental work can certainly help companies worldwide to improve the state of the art in aerospace.

5. The use of propellant depots might mean an important change in international cooperation for space exploration. It provides more possibilities for modularity in that multiple nations can provide different “bricks”, much like on the International Space Station. Europe, for example, could provide an automated cargo vessel based on their ATV but compatible with the new architecture.

These points show that the proposal under discussion has a lot of potential to create the mindset in which a “commercially based” architecture might be realized. However, an important point, made earlier, remains: for a sustained and predictable business-case closing cash flow, exploration efforts need a solid long-term plan. A plan that needs to be based on more than “we’ve been there before. Buzz has been there.”

The flexible path approach is an approach with clear advantages. But it remains an approach—an answer to the “what?” question—not a strategy answering “why?” It is meant to be a proving ground for space hardware, a good approach in its own right. But what this plan currently lacks is a clear vision on what to do with this flexible space infrastructure once proven. If such a plan is not in place, any future architecture risks not going beyond a series of firsts, and the space program risks being reduced again to “flags and footprints”. What’s more, in this case, the “airmail” bonus to commercial spaceflight does not apply, as there is no guaranteed long-term demand for the hardware. That means closing a commercial spaceflight business case gets harder, and risks seriously limiting competition for the different ‘bricks’ in the architecture.

| The flexible path approach is an approach with clear advantages. But it remains an approach—an answer to the “what?” question—not a strategy answering “why?” |

Waiting for results from the proposed technology demonstration missions before settling on a long-term architecture (what? how?) is a careful approach. However, it does not exclude already making a clear decision on what the answer will be to the “why” question. One answer, the Vision for Space Exploration, is probably still valid today: going to the Moon, to stay, could be an important stepping-stone, and a driver for infrastructure development.

Considering the pros and cons mentioned above, a personal conclusion is that this new plan has a much better chance than the Constellation architecture of actually realizing the worthwhile goal of a sustainable human presence in space. This plan enables the construction of an infrastructure in and of space, brick by brick, potentially boosting the worldwide space industry and showing humanity the way into the solar system. On one condition: that there is at least some “business case closing” idea of what the architecture is going to be used for in the long haul.

References

1 Hjelmgaard, K., “Brick by brick: How Lego’s fortunes transformed”, MarketWatch, December 23, 2009

2 Zegler, F. , Kutter, B. F., Barr, J., “A Commercially Based Lunar Architecture”, AIAA Space 2009 Conference (AIAA 2009-6567).

3 Spudis, P., “Why We’re Going Back to the Moon”, The Washington Post, December 27, 2005

4 “Cost-plus contract” on Wikipedia

5 Goff, J. A. et al., “Realistic Near-Term Propellant Depots: Implementation of a Critical Spacefaring Capability”, AIAA Space 2009 Conference (AIAA 2009-6567)

6 Klamper, A., “Orion Lifeboat Making Waves for Boeings Commercial Crew Plans”, SpaceNews.com, May 21, 2010

7 National Research Council, Committee on the Assessment of NASA Laboratory Capabilities, Capabilities for the Future: An Assessment of NASA Laboratories for Basic Research, May 2010