Burning thunderby Dwayne Day

|

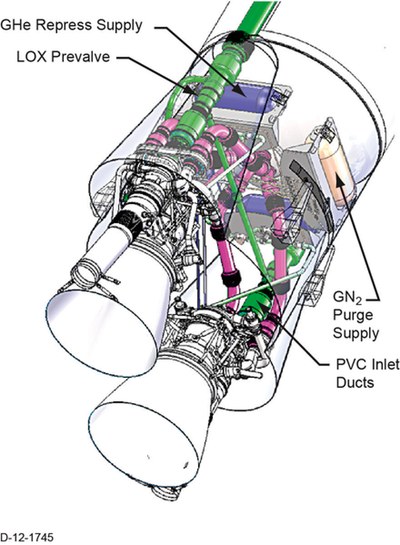

Inside the halls of Dynetics, engineers are working on using the F-1 to help boost later versions of the SLS. (credit: Dynetics) |

Resurrecting a giant

After the Saturn V became a memory, it rapidly developed its own mythology. One of the myths that grew up around it was that NASA “lost” the blueprints, or even worse, deliberately destroyed them, sort of like burning one’s ships so that your crew could only go forward. That was untrue. In fact, NASA had an active knowledge retention program to preserve information about many of Saturn’s components, most importantly the engines. Even though NASA had already started development of the Space Shuttle, many within the agency hoped that they could do other projects in the future, and they might someday need the Saturn’s engines, including its hydrogen/oxygen powered J-2 engine that equipped the rocket’s second and third stages, and the massive kerosene/oxygen powered F-1 that gave the Saturn its initial lift. In the early 1990s, Rocketdyne proposed restarting F-1 engine production for a new rocket. Their engineers believed that they could make it less expensive than during Apollo, although those plans never progressed very far. The company revisited these plans several times in the intervening years.

| And now some people are hoping for the F-1 to make a comeback. |

Although the F-1 and J-2 engine plans still existed, over time NASA and the companies involved in the production of these rockets lost knowledge about them as people retired or forgot about how to operate them. In addition, manufacturing processes changed, meaning that even if these engines were revived, they would not be built in the same way they had during the 1960s.

The J-2 engine has been resurrected, with NASA and manufacturer Pratt & Whitney Rocketdyne (now Aerojet Rocketdyne) testing the engine at Stennis Space Center. The J-2X is planned to serve as the upper stage engine for the Space Launch System, or SLS. Now some people have begun to revisit the idea of using the F-1 again. In 2012, NASA awarded a study contract to a team led by the Huntsville-based company Dynetics and including the original F-1 manufacturer, Rocketdyne. The companies will investigate the potential for using the F-1 in boosters attached to an updated version of the SLS. NASA issued several contracts for the Advanced Booster Engineering Demonstration and/or Risk Reduction effort. Dynetics is a company that provides engineering solutions for the defense, aerospace, and commercial industries. The company has grown rapidly in recent years, including opening a new high-tech research and development facility known as its Solutions Complex, with a central spine hallway running down the long building that gives it the look of a high-tech development complex straight out of a Hollywood movie.

NASA is currently building the SLS as a heavy-lift rocket to boost humans beyond low Earth orbit. Right now the plan is for SLS to be built and upgraded in blocks. Block 1 is planned for first flight in 2017, with a follow-on flight in 2021. It will be capable of carrying 70 metric tons into orbit using four RS-25 (Space Shuttle Main Engine) core stage engines and five-segment solid rocket motors. The second stage will consist of a Delta IV upper stage. NASA currently owns 25 RS-25D engines left over from the Space Shuttle program, but only 16 are useable for the SLS program and they will not be recovered. These would eventually be replaced by the RS-25E, designed to be a cheaper, expendable version of the same engine.

Although it is not yet officially planned to fly, a Block 1A version of the SLS could enter service after 2021. It would add advanced boosters, increasing the payload capability to 105 tons, but would not incorporate the J-2X engine in its upper stage. Block 2 would add a completely new upper stage incorporating J-2X engines, and would have a nominal capability of placing 130 tons into low Earth orbit. By comparison, the Saturn V was capable of placing 118 tons into orbit, and 45 tons on a translunar injection trajectory.

Illustration of an SLS launching with Pyrios boosters, powered by F-1 engines. (credit: Dynetics) |

The F-1B and Pyrios

In October 2012, the Dynetics-led team was awarded a 30-month, $73.3-million contract to study several aspects of the advanced booster, including risk reduction for the engine and the booster structure. This could eventually lead to developing advanced boosters each powered by two F-1 engines. NASA has also been studying the F-1 largely as a training effort to develop engine design skills for younger engineers.

| If NASA adds two advanced boosters each powered by two F-1B engines to the SLS core stage, this would actually boost the overall SLS Block 2 performance to 150 metric tons, 20 tons over the requirement. |

Aerojet Rocketdyne has designated the new engines as F-1B. During the early 1970s Rocketdyne apparently used the designations F-1B and even F-1C for possible future versions of the engine. At least one of these rocket engines would have been for a reusable flyback Saturn S-IC first stage. In addition to the proposed early 1990s revival of the engine previously mentioned, by the late 1990s Rocketdyne considered using a version of the engine in a flyback booster for the Space Shuttle, this time designating it the F-1 Block II. More recently, the company evaluated an “F-1C” design for a commercial customer—probably United Launch Alliance—but that project did not go forward and therefore no details have been made public.

If NASA adds two advanced boosters each powered by two F-1B engines to the SLS core stage, this would actually boost the overall SLS Block 2 performance to 150 metric tons, 20 tons over the requirement. The team investigating the F-1 approach has calculated that if they emphasized performance over cost, they could achieve at least 160 metric tons, but at high cost. But Dynetics’s goal is to drive down cost wherever possible, and the F-1B would already provide more performance than current NASA mission concepts require.

During their initial evaluation, the Dynetics-led team looked at several booster/tank diameter combinations. Other options included three RD-180 and three RS-84 engines. The RD-180 is the Russian-built engine currently used to power the Atlas V rocket. The RS-84 was a proposed Rocketdyne LOX/kerosene rocket engine capable of approximately 5.16 million newtons (1.16 million pounds) of thrust. The RS-84 was supposed to be reusable, but it was not pursued to actual testing, and development ended in the early 2000s.

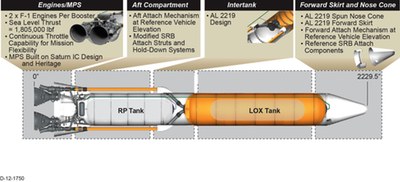

Dynetics has named their booster Pyrios, after one of the horses that pulled Greek sun god Helios’ chariot. Pyrios would consist of a boattail and aft skirt above two F-1B engines. Above this would be the kerosene fuel tank, an intertank, a liquid oxygen tank, a forward skirt, and a nose cone. Pyrios would have the same attachment points as the SRBs on the Block 1. To reduce cost, the booster tanks and skirts would use Aluminum 2219 friction stir welded into structures 5.5 meters (18 feet) in diameter.

The Dynetics-led team has looked at a family of booster options, including a Block 1A rocket with their boosters, which would be capable of 103–120 metric tons, and a “Single-Stick” rocket with the canceled Ares I J-2X-powered upper stage capable of launching 32 tons.

The engine would use the proven elements of the F-1 and the simplifications and performance enhancements of the F-1A. Several F-1A engines were built and tested as a follow-on to the F-1 engine. The new engine would be capable of 8 million newtons (1.8 million pounds) of thrust at sea level, which could be throttled down to 5.8 million newtons (1.3 million pounds.) This allows operators to tailor the thrust profile for each flight and vehicle configuration as necessary.

The new engine would include a number of modernized low-cost components. These are a hot-isotatic press bond constructed channel wall main combustion chamber and channel wall nozzle. The F-1 is a gas generator cycle engine using low pressures. A gas generator engine uses some of its propellant to turn the turbomachinery before venting it outside of the exhaust.

The original F-1 and F-1A had a large exhaust manifold that curved halfway down the outside of the exhaust nozzle and vented into the nozzle. The exhaust, although hot, was significantly cooler than the hot gasses in the thrust chamber, and the cooler exhaust flowed down the inside side of the nozzle, serving as a heat buffer and preventing the primary exhaust from burning through the nozzle. Two of the highest cost engine components, the turbine exhaust manifold and nozzle extension, would be eliminated in the F-1B, and the tube wall thrust chamber assembly would be replaced. Dynetics has released concept illustrations and displayed a model showing the new engine with a large exhaust duct running down the side of the exhaust bell rather than curving into the bell like on the F-1A, thereby simplifying construction of the exhaust structure. It looks distinctly different from the F-1A, but it is still massive. Because of the lower pressures in a gas generator engine it can be constructed out of conventional and low-cost materials such as aluminum throughout the primary flow paths.

| If budget cuts demand it, NASA could abandon the J-2X upper stage and instead go with the Block 1A version of the rocket, which would certainly benefit from the increased performance of the F-1B advanced boosters. |

Modern technology makes it possible to make a number of other changes to the engine to improve overall performance, reliability, and ease of manufacture. The original F-1 engines were essentially hand-crafted, with many parts being welded together by a skilled welder. Although computer-controlled machines are now capable of taking over many welding jobs, engineers prefer to avoid welding whenever possible, casting a few large parts rather than welding together many smaller ones. As a result, they have reduced the parts count on one major section of the engine from 5,600 individual parts to only 40. That reduces cost, increases reliability, and simplifies many other processes. No more hand-crafted welding required.

Another major change is how the engine starts up. The original F-1 was built somewhat like a wind-up clock: as one part of the startup sequence occurred it would mechanically or in some other way trigger the next part of the startup sequence and so on. Those who have looked at it today marvel at how clever it is. But they plan on replacing most of that with modern computer-controlled systems, which should also increase their ability to control and fine-tune the engine.

The Dynetics-led team is pursuing a 30-month duration risk reduction plan as part of this work. They will build a full-scale cryotank assembly for Pyrios in order to verify the structural design.

Diagram of the F-1 engines incorporated into the Pyrios booster. (credit: Dynetics) |

Go big or go extinct

If they are someday selected, the Pyrios boosters with their F-1B engines would replace the five-segment Solid Rocket Boosters currently under development for the SLS. But Pyrios is not the only possible option for the SLS Block 2. ATK, which produced the fuel for the Space Shuttle’s Solid Rocket Boosters and is developing the upgraded five-segment version of the shuttle booster for the SLS, has also proposed an advanced booster and received a contract from NASA to further study it.

The advanced booster would have a composite case made from low-cost, high-strength fibers, and would reduce the number of segments from five to four, although the overall length would remain the same as the boosters currently under development for Block 1. It would also incorporate an electric thrust vector control system, simplified forward and aft structures, and design features to improve launch site processing. The fuel mixture would be a higher-energy hydroxyl-terminated polybutadiene propellant instead of the polybutadiene-acrylonitile used for the shuttle and the Block 1 SLS. According to ATK, in order to achieve the 130-metric-ton payload requirement, the ATK solid booster would also require a fifth RS-25 engine in the SLS core stage.

The most notable difference between the Block 1 solid rocket boosters and the proposed Block 2 advanced solid boosters is an oblique nose cone, angled toward the SLS core segment and similar to the boosters on the Ariane 5. ATK artwork of the booster depicts it a different color than the white-painted boosters used for the shuttle program. Of course the booster could still be painted white, although paint adds mass to the vehicle—the core stage of the SLS is currently white in artist images, but will be covered by the same insulation used for the Space Shuttle’s external tank and will most likely be the same orange color.

Diagram of the overall Pyrios booster. (credit: Dynetics) |

Rockets in flux

Although the SLS Block 1 is nearing its final definition, later refinements are still undetermined. The SLS design is still in some flux, although in late 2012 the core stage passed a key stage in development, the preliminary design review. The latest publicly available data on the rocket indicate that the core stage is being designed to the more robust requirements of the Block 1A version rather than the Block 1, enabling it to include the advanced boosters without additional modifications. This makes sense, because NASA’s goal is to eventually upgrade the rocket and it is cheaper to include certain aspects from the start rather than adding structure to a finalized design that might fly only a few times. But it also means that if budget cuts demand it, NASA could abandon the J-2X upper stage and instead go with the Block 1A version of the rocket, which would certainly benefit from the increased performance of the F-1B advanced boosters, enabling it to achieve nearly the Block 2 performance goals. A bigger upper stage, possibly provided by a foreign partner like Japan, could be added later.

| Although the J-2X is a legacy design, it uses modern materials and components. Its development has been slowed down to save money, and NASA will be throttling engine development budgets the way it seeks to throttle rocket engines. |

But as with any complex system, the devil is in the details. Any change to the Block 1 SLS will require changes to the ground infrastructure that supports it. For example, adding liquid booster rockets to the SLS will require changes to the Mobile Launch Platform to enable kerosene and additional liquid oxygen to be pumped into the rocket on the pad, and will also require additional liquid oxygen storage at the launch site as well as provision for kerosene storage. Although Launch Complex 39B was originally built to support the Saturn V and had provision for kerosene storage, the storage tanks and piping were removed when the facility was converted to the shuttle program and would have to be rebuilt.

NASA has undertaken extensive work to turn LC-39B into a “clean pad” capable of operating different kinds of boosters, which will bring their support infrastructure with them atop the Mobile Launch Platform. Part of this work has involved changing the massive flame trenches underneath the pad. Although the pad looks like a concrete mound that rises up from the nearly sea-level ground around it, the pad is actually a hollow structure covered in concrete, and in June construction crews began cutting into the pad so that the flame trenches—which have eroded after dozens of shuttle launches—can be reformed.

Along with the ATK and Dynetics contract awards in summer 2012, NASA also selected a booster-tank proposal for Northrop Grumman’s Aerospace Systems. The company will build a subscale composite tank. In addition, Aerojet General Corp. has been working on an Air Force contract to develop its AJ-1E6 engine capable of 4.4 million newtons (one million pounds) of thrust (“1E6” is engineering terminology for one followed by six zeros). The AJ-1E6 is a modified version of the Russian NK-33 engine used for the Soviet N-1 Moon rocket and now powering the first stage of the Orbital Sciences Antares rocket. The AJ-1E6 could also power advanced boosters for the Space Launch System.

Rocketdyne is wrapping up the J-2X liquid oxygen-hydrogen engine for the Block 2. This project was started during the previous Constellation program and was supposed to serve as the upper stage engine for both the Ares I and Ares V rockets. Although the J-2X is a legacy design, it uses modern materials and components. Its development has been slowed down to save money, and NASA will be throttling engine development budgets the way it seeks to throttle rocket engines.

Fire and smoke

The January test of the gas generator at Marshall Space Flight Center was only the first of eleven planned tests and has since been followed by several more. It was conducted by NASA, which has been taking apart and examining several legacy F-1 engines as part of an engineering training program independent of the Dynetics and Rocketdyne work. NASA has already scanned some of the engine components as the first part of a process intended to make it cheaper to manufacture them in the future. After completing its tests, NASA will turn over its data to the Dynetics team, and Rocketdyne will conduct tests of the full engine powerpack, consisting of both the gas generator and the turbomachinery, but without the engine’s thrust chamber. Powerpack tests allow engineers to more fully explore the engine operating conditions, determining the best fuel mixtures, internal pressures, and other criteria. The company has no current plans for a test of a complete F-1B engine.

NASA engineers have calculated that sending a human mission to Mars orbit—not even landing—could require up to 400 metric tons sent to the Earth-Moon L1 departure point. This is a huge amount of mass, roughly equivalent to the International Space Station. Such a mission would require twenty launches of an SLS Block 1, or ten launches of an SLS Block 2. At the current planned rate of one launch every few years—dictated solely by projected budgets and not operational limitations—such a mission would not be possible. During congressional testimony in mid-June, several highly-respected longtime advisors to the United States’ civil space program were asked when they thought it would be possible to send humans to Mars given currently projected funding levels. Their response was sobering: “Never.”

The last time a Saturn V rocket powered by F-1 engines lifted off was the Skylab Orbital Workshop in 1973. There is a long way to go between the current fiscal situation and sending humans beyond low Earth orbit. But perhaps, on some clear night in Florida in the 2020s, the sky will once again glow orange and it will appear as if the sun is rising out of the swampland. Slowly, ever so slowly, an SLS Block 2 will lift off the ground. It would be over half a century later, but the mighty F-1 would once again burn and its thunder will echo across the swamps and the ocean, pushing humans once more into deep space.