First west, then eastby Ronald P. Menich

|

| Ceteris paribus, the goal of minimizing the number of stages is a good one. However, launch vehicle engineering involves tradeoffs between many different and often conflicting objectives. |

With respect to the latter goal, the US pursued the single stage to orbit (SSTO) National Aerospace Plane (NASP) project in the late 1980s for several years before it was ultimately canceled in 1993. NASP was to be a hypersonic scramjet, a waverider designed to accelerate to Mach 20 within the atmosphere using slush hydrogen and other exotic technologies.

Finding SSTO a bridge too far, NASA’s and the USAF’s advanced reusable systems research eventually changed focus to two stage to orbit (TSTO) systems. Considering that some expendable systems are now TSTO, this focus seems reasonable on the surface. However, it is far more challenging to design a fully reusable TSTO system than an expendable one because fully reusable systems need to carry additional mass for systems such as landing gear, wings, thermal tiles, and the like, which expendable stick rockets need not carry. Many proposed fully reusable TSTO systems also have the requirement that the first stage reverse course and execute a powered return to base, a requirement that expendable TSTO systems need not bear.

Because of these strenuous requirements, many proposed fully reusable TSTO systems have been very complex. For example, consider the turbine-based, combined cycle (TBCC), two stage to orbit system which has been studied by NASA for years. This incredibly complex system, similar in some respects to NASP, has on its hypersonic first stage rockets, very high performance turbojets, and also scramjets. The planned flight profile involves the first stage cooking in the heat as it accelerates to Mach 10 through the atmosphere, eventually releasing its second stage, reversing course and then suffering a hypersonic 1000-mile return to base. Another fanciful system involves an inward-turning, rocket-based combined cycle (RBCC) second stage, boosted to supersonic speeds by a rocket first stage.

Ceteris paribus, the goal of minimizing the number of stages is a good one. However, launch vehicle engineering involves tradeoffs between many different and often conflicting objectives. If reducing the number of stages in a fully-reusable system to one or even two requires ultra-advanced technologies, then it is reasonable to question how much weight or attention should be given to the objective of so severely limiting the number of stages. The Soyuz family of expendable launchers has three stages and has been launched over a thousand times, routinely launching humans and automated Progress resupply vehicles to the International Space Station with little fuss: the stages are mated horizontally and nominally it takes two days or less from rollout of the mated vehicle to launch.

Instead of focusing on fully-reusable SSTO or TSTO systems with highly advanced technologies, another possibility for reusable ETO launcher design is three stage to orbit (3STO) designs, which use existing building blocks whose performance has been proven over many years and combined in novel ways. Historically, ETO system designers have found it difficult to conceive of how to achieve reusability with 3STO systems; e.g.

“Three Stage To Orbit (3STO) systems face additional challenges in the recovery of the middle stage, as it is very far downrange, yet has insufficient velocity to circumnavigate the planet.” (ref.)

Alternatively, 3STO designers have specified landing sites different from the launch site, which introduces operational complexity.

| Historically, ETO system designers have found it difficult to conceive of how to achieve reusability with 3STO systems. |

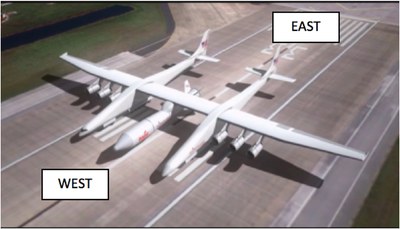

We will illustrate an approach to circumventing these conceptual operational difficulties. Consider a three-stage, fully-reusable, horizontal takeoff/horizontal landing, ETO launch system that launches payloads into a low Earth orbit of the same low inclination as that of the launch site. The first stage is a subsonic carrier aircraft similar in concept and overall size to Stratolaunch, with conventional turbofan engines. The second and third stages are rocket-propelled. All three stages land on the same runway from which the stack originally launched.

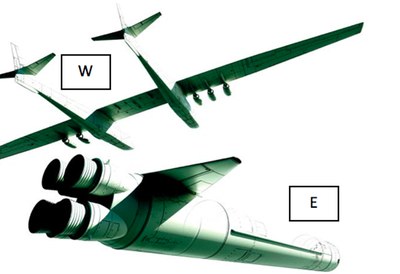

The combined stack launches from the runway and initially heads west. After some time it eventually makes a 180-degree turn, heads back east and then air launches the all-rocket second- and third-stage stack. The second stage fires, gaining velocity while heading east towards the launch site. Eventually the second stage shuts down, separates from the third stage and then the third stage fires. The third stage passes over the launch site on its way to orbit.

The air-launch system turns to the east and deploys the rocket stage. |

The second stage maintains an eastward heading, eventually shutting down its engines and landing after an unpowered glide forward to the launch site. The distance that the original three-stage stack initially heads west is exactly calculated so that the second stage can land forward to the launch site. The first-stage carrier aircraft also lands at the launch site. After depositing its payload in orbit, the third stage de-orbits and it also lands at the same launch site.

The upper stage, like this X-37B, lands to the east at the launch site after placing its payload in orbit. |

No technology used on this ETO launch system need be particularly exotic. Millions of people per day fly on turbofan aircraft. A launch stack of the size planned for Stratolaunch is large, but the maximum takeoff weight for the commercial A380 is comparable, and the AN-225 had a yet larger maximum takeoff weight two and a half decades ago. Chuck Yeager’s rocketplane was air-dropped from an aircraft two years after the end of World War II. The second and third stages are rocket-driven stages with far fewer requirements imposed on them than the Space Shuttle orbiter had four decades ago, and thermal protection technology has advanced in the interim. Studies have been performed illustrating that an all-rocket, fully-reusable TSTO design with sufficiently high-performance engines is capable of launching payloads to orbit; one way of thinking about the 3STO design discussed in this essay is as a variant of that all-rocket TSTO system, but relieved of part of its velocity change requirement by the turbofan carrier aircraft.

Regarding the second stage of the 3STO system, no complicated aerobatic rocketback maneuver is required, no deep throttling of the engine is needed to support the non-existent rocketback, there is no requirement to relight the engine after third-stage separation, nor is there any need for jet engines for powered return to base. The second stage does not have any cross-range requirement and can have wings only as large as are required to safely glide unpowered and land. In TSTO fully-reusable designs, the first stage must reverse course and execute a powered return to base; in this 3STO design, that requirement is entirely eliminated: the carrier aircraft, operating at several thousand seconds of specific impulse, absorbs that requirement completely by first heading west before reversing course, heading east, and then executing the air launch.

Stratolaunch, which plans to drop a “Pegasus II” rocket stack with expendable components, is projecting a 6,100-kilogram payload capability. Because the 3STO system described here has fully-reusable components with attendant weight penalties, it will likely have considerably less payload capability than Stratolaunch for comparable launch sites, perhaps 3,000 kilograms. Detailed engineering analysis of specific point designs—designs which specify propellants used, engine performance, thermal protection material choices, etc.—is needed to ascertain actual achievable payload.

| Dropping the SSTO and TSTO obsessions and exploring fully reusable 3STO options such as the one proposed in this essay can enable practical full reusability using today’s technologies. |

One of the great virtues of fully reusable systems is that their operational costs can be lower than that of expendable systems. If properly designed, it is economically possible to support a higher flight rate than expendable systems and to amortize the design, development, test, and evaluation (DDT&E) costs over a large number of flights, eventually leading to lower average costs than expendable systems at sufficiently high flight rates. It is possible to launch smaller payloads on each launch but yet launch more in a year in toto than a much larger expendable system could do. Though it might seem small, it is useful to note that a 3,000-kilogram payload capacity is both larger than that of the Mercury spacecraft capsule and approximately the same as that of the famed DC-3/C-47, an aircraft of which over 10,000 were built, pioneering large-scale air travel and supporting important and massive cargo operations such as the Berlin Airlift. Full reusability can have tremendous advantages at high flight rates.

We’ve described a fully reusable 3STO system that could launch humans and payloads to orbit and requires no advanced technologies that have not already flown successfully many times. There are undoubtedly other 3STO designs that could achieve similar or even better results.

Dropping the SSTO obsession in the aftermath of the NASP cancellation allowed NASA and the USAF to study slightly more achievable fully reusable TSTO designs, but the resulting TSTO designs still required advanced technologies, so even TSTO might still be a bridge too far. Given that turbofan aircraft transport millions of people per week and that air launches have been performed hundreds of times, strenuously avoiding a first stage air launch in order to keep the number of stages limited to two does not seem to be a reasonable design constraint at this time. First heading west before heading east enables consideration of three-stage, fully reusable, and highly operable designs. Dropping the SSTO and TSTO obsessions and exploring fully reusable 3STO options such as the one proposed in this essay can enable practical full reusability using today’s technologies.