The Big Gby Dwayne Day

|

| McDonnell Douglas’ Big G proposal was a bit complicated. The spacecraft could come in several forms depending upon what NASA wanted and how much the agency wanted to use existing equipment. |

Like all government contractors, McDonnell Douglas was looking to expand their customer base. The company had pitched civilian versions of MOL to NASA even though NASA was planning on using Apollo hardware as the basis of future space stations. In summer 1967, McDonnell Douglas proposed a new variant of its Gemini spacecraft known as the “Big Gemini,” or “Big G.” By December 1967, the company prepared a 100-page briefing booklet for NASA with “Big G” printed on the cover. The briefing booklet made the case for a new spacecraft for NASA even though NASA was not in the market for one.

The company briefing stated, “In the 1970–1980 period, it appears that at least a dozen launches will be required for logistic purposes.” Although the Apollo Command and Service Module could service the first planned orbital workshop, which was then expected to launch in 1970, McDonnell Douglas argued that an improved and more versatile cargo vehicle would be useful for the “Orbital Workshop No. 2,” which the company expected would be launched in 1971.

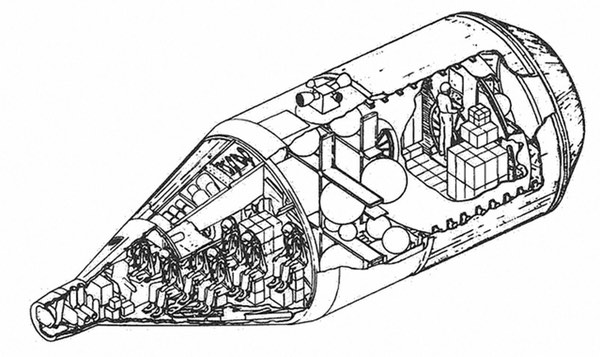

According to McDonnell Douglas, the Gemini B that the company was going to build for MOL could essentially serve as the cockpit for a larger spacecraft that could carry astronauts up to low Earth orbit and be ready to fly by 1971. With a module attached to the back of the Gemini, the spacecraft would be capable of carrying up to twelve astronauts, although the baseline design was for six. Because Gemini B already had a rear hatch that enabled its astronauts to exit through the rear of the vehicle, this would allow them to move into the back of Big G, where the passenger astronauts would ride. Another tunnel in the back of the enlarged section would allow those inside to leave the craft when it was docked to a space station or a pressurized logistics vehicle.

McDonnell Douglas’ Big G proposal was a bit complicated. The spacecraft could come in several forms depending upon what NASA wanted and how much the agency wanted to use existing equipment. At the front would be the Gemini B and behind it would be a pressurized conical extension. This extension’s base would be 154 inches (3.91 meters), the same diameter as the Apollo Service Module, and a Service Module could be attached if that’s what NASA wanted. The spacecraft would be equipped with an Apollo-style escape tower and a retrorocket for de-orbiting.

Instead of a Service Module, McDonnell Douglas’ suggested design included a Maneuvering and Cargo Module that extended even farther out, giving the spacecraft a diameter the same as the Saturn S-IVB stage. This module included propulsion for orbital maneuvering, electrical power, a pressurized and unpressurized volume for cargo, a pressurized transfer tunnel, a station for controlling docking, and an Apollo Docking Probe Assembly. The goal was to provide expendables for six men for 90 days in orbit. The docking solution was unusual. After approaching the space station to a range of approximately 100 miles (160 kilometers), the spacecraft would then yaw 180 degrees and an astronaut in the rear docking station would fly it backwards to dock with the space station.

At the time, NASA’s Manned Spacecraft Center in Houston had hired McDonnell Douglas to study an Advanced Logistics Spacecraft. But the ALS would be a new-build spacecraft, and McDonnell Douglas proposed Big G as an interim solution, more capable than Apollo and ready in the near term, before ALS. For missions to the orbital workshop, two or more Big G spacecraft might be attached at the same time.

Although McDonnell Douglas claimed that Big G would use the Gemini B and its systems as the core of the vehicle, this was a bit of a stretch. The Gemini B would not have its heat shield nor the standard landing parachute. It would have to include a rendezvous radar developed for the NASA Gemini but omitted from the Gemini B. It would also have to be modified for a skid landing gear in the nose. The cockpit systems and controls would have to be modified to control a larger and more complicated spacecraft. There was also the possibility that the structure would require modification to handle new loads as well. The astronauts would use their normal hatches for getting into the vehicle on the pad, and the pressurized section would also have hatches on either side for the additional astronauts.

| Perhaps the most unusual aspect of Big Gemini was its landing method, which the company considered so attractive that an illustration of the landing spacecraft appeared multiple times throughout the report. |

The original Gemini launched atop a converted Titan II ICBM. Big G could be launched by several different rockets depending upon the spacecraft configuration. The launch vehicle options included the Titan IIIM then under development for the MOL program, although this would have required a smaller diameter maneuvering and cargo vehicle. But larger and more complex versions of Big Gemini could fly into space atop a Saturn IB, or a modified Saturn V rocket cut down for Earth orbital work.

Perhaps the most unusual aspect of Big Gemini was its landing method, which the company considered so attractive that an illustration of the landing spacecraft appeared multiple times throughout the report. Unlike earlier spacecraft, Big G would come down on land. The spacecraft would be equipped with landing skids. NASA had evaluated land landing for Gemini using a triangular-shaped inflatable parachute known as a Rogallo Wing. But the Rogallo Wing experienced problems during development, both with proper inflation and deployment as well as steering. The Rogallo Wing’s problems threatened to delay the Gemini program and it was canceled in favor of traditional parachutes and a water landing.

In McDonnell Douglas’ December 1967 proposal, the company offered several options including a sailwing, cloverleaf parachute, parawing, and parafoil. The parawing was similar to Rogallo’s earlier design. The goal was to develop a parachute that would provide the spacecraft with some lift and forward velocity, so it would—in theory at least—come down to a gentle near-horizontal landing on the ground. This was important because of the large number of astronauts who might be inside the spacecraft. Having a dozen people inside a spacecraft bobbing in the ocean would create numerous problems and risks. Having a dozen seasick astronauts inside a spacecraft would also be unpleasant.

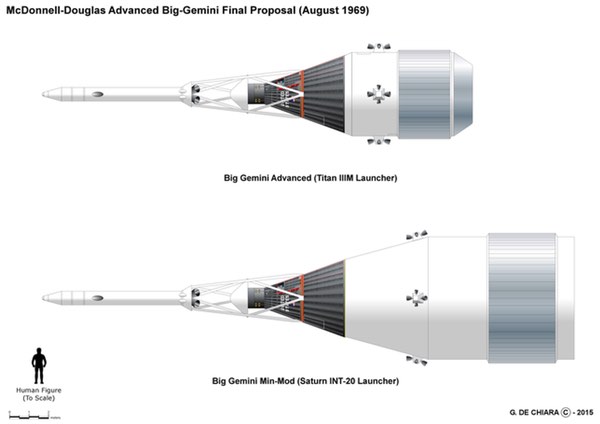

Illustrations of the Advanced and Min-Mod versions of Big G studied by McDonnell Douglas for NASA. (credit: Giuseppe Chiara) |

Big study for Big G

In August 1968, NASA agreed to a contract with McDonnell Douglas Astronautics Company to study Big G. However, only a short time later, George E. Mueller, NASA’s Associate Administrator for Manned Space Flight, gave a speech at the British Interplanetary Society in London where he discussed NASA’s future space plans and stressed the desire to reduce the cost of operating in space. Mueller for the first time publicly mentioned a vehicle that NASA was considering building called a “space shuttle.” This would become Big G’s primary competitor.

NASA and McDonnell Douglas signed a $436,000 study contract for Big G in early October 1968. The study was to cover a minimum cost approach to providing logistic resupply to a space station or space base and the ability to carry up to nine astronauts. NASA was also initiating studies for an Integral Launch and Reentry Logistics Vehicle (ILRV) to begin operating in the 1975 time period, the forerunner of the space shuttle. By January 1969, NASA signed ILRV contracts with McDonnell Douglas, North American Rockwell, General Dynamics, and Lockheed. By this time Thomas Paine was acting administrator at NASA and, according to one account, Paine favored Big G over an “Apollo derivative” for NASA’s future space needs. Paine would become NASA administrator in March 1969, but there is no indication that he was enthusiastic about Big G.

Also by January McDonnell Douglas engineers conducted a mid-term briefing on Big G at the Manned Spaceflight Center (MSC—renamed the Johnson Space Center in 1973). This briefing raised an important question about whether or not the astronauts would wear spacesuits or operate in a shirtsleeve environment. Caldwell Johnson, Chief of the Spacecraft Design Office, sent a memo to Maxime Faget, Director of Engineering and Development at MSC suggesting that the astronauts would wear “pressure garments” during flight and this might even allow the elimination of the environmental control system on the spacecraft.

Faget shot down that suggestion in a January 13 memo to Johnson:

We made a mistake when we did not design the Apollo Command Module for shirtsleeve crew operation. Objections to this approach were voiced by FCOD [Flight Crew Operations Directorate], FOD [Flight Operations Directorate], and the Medical people and their views prevailed over the designers who pointed out that greater safety could be obtained by applying the same weight and financial resources into a safer cabin, etc. These same factions have changed their views and not only have confidence in the basic cabin structure, but see virtue in the additional freedom afforded the astronaut by removal of the bulky suit. I therefore see no basis at all for further consideration of the use of pressurized garments within the logistic spacecraft (including launch and reentry flight plans). The many benefits in simplification and cost savings accrued by not encumbering the spacecraft with those many complicating features required to support pressure-suited occupants overwhelm any argument that such features should be maintained to cater to archaic requirements on a contingency basis or for other traditional considerations.

What Faget did not mention, but was certainly a factor in his calculation, was that having more astronauts only increased the complications considering that they all would have had to plug into connectors for air and cooling and possibly health monitoring as well. Furthermore, carrying six to nine spacesuits would add a lot of mass and take up a lot of room. It simply was not a viable solution.

| As McDonnell Douglas was preparing to deliver the study to NASA in summer 1969, they suffered a shock when President Nixon canceled the MOL program. |

In August 1969, McDonnell Douglas presented an eight-volume Big G study to NASA. It was an exhaustive report. Volume 2, for instance, covered spacecraft design and performance, whereas Volume 7 addressed refurbishment and reuse. The summary stated that “this study applied the design philosophy that the spacecraft should be designed to function like a truck.” Although the basic Big G concept remained the same, it had evolved from the preliminary 1967 proposal. One late change was the elimination of the Saturn IB as a potential launch vehicle, keeping the Titan III and modified Saturn V options.

The spacecraft would consist of a crew module with a 165-inch (4.19-meter) diameter heat shield—slightly bigger than the 1967 proposal—and a cargo propulsion module. The spacecraft would use a parawing, or gliding parachute, for recovery, and skid landing gear would allow the crew to land in an upright position. It would also be equipped with an emergency flotation system for water landings. A single liquid propellant system would be used for transfer, rendezvous, attitude control, and retrograde propulsion. An Apollo-type escape tower would be used for launch escape.

McDonnell Douglas had settled on two proposals, a “Min-Mod Big G” and an “Advanced Big G,” both having the 40-degree cone angle shape of the Gemini. The Min-Mod spacecraft emphasized low development costs and early availability, whereas the Advanced Big G would have the same configuration but new subsystems, essentially replacing the Gemini B spacecraft that served as the cockpit for the Min-Mod vehicle.

The Min-Mod vehicle could carry nine astronauts and a minimum return cargo of 2,000 pounds (910 kilograms). The Advanced vehicle could carry twelve astronauts and the same amount of cargo, although either version could accommodate up to sixteen men if required.

A Cargo Propulsion Module was located behind the crew module and housed the maneuvering propulsion system and support equipment as well as cargo and the docking mechanism. The study considered two CPM configurations. A 297-inch-long (7.54-meter-long) CPM would be used for a Titan IIIM launch vehicle; this included a 50-inch (1.27-meter) structural adapter that remained attached to the launch vehicle at separation. It would be a 180-inch (4.57-meter) diameter cylinder, larger than the 120-inch (3.05-meter) diameter Titan core stage, thus giving the launch vehicle a hammerhead shape that the designers felt was acceptable based on wind tunnel tests.

If the spacecraft was launched atop a modified Saturn launch vehicle known as the INT-20, the CPM would be 489 inches (12.4 meters) long (with a 24-inch (0.6-meter) structural adapter) and 260 inches (6.6 meters) in diameter along with a forward cone tapering to the 165-inch diameter of the crew module. It would have far more internal volume and capability.

The crewmembers would be provided with foldable web-type seats. There were internal and external cargo stowage areas. Standard cargo container size was 1 by 1 by 2 feet (0.3 by 0.3 by 0.6 meters) and these could be latched together as well as to the supporting spacecraft structure. For the Advanced version, the cargo was located in compartments under the floor with no side compartments. For both vehicles the crew could be seated in different arrangements.

The Min-Mod vehicle would use batteries for power, whereas the Advanced version would use a combination of batteries and fuel cells to increase flexibility and save weight.

McDonnell Douglas estimated that a Min-Mod vehicle could undergo flight test 37 months after program initiation, with the first operational vehicle following six months later. The Advanced version was estimated to take only three months longer.

As McDonnell Douglas was preparing to deliver the study to NASA in summer 1969, they suffered a shock when President Nixon canceled the MOL program. The company hastily revised their report to address that issue, stating that it would have no impact on their ability to build Big G. They stated that Gemini B existing data and hardware were in storage and production tooling was 95 percent complete. Key personnel were also being retained.

Reusability was a major aspect of reducing costs and the company indicated that there were several different approaches that could also reduce costs. Water landing would lower costs for low flight rates, primarily because the spacecraft could use a less expensive parachute system and eliminate the landing gear. Another approach included incorporating the launch vehicle guidance systems into the Big G so that they could be reused rather than discarded with the launch vehicle. This would provide greater savings for the Saturn INT-20 than the Titan IIIM.

A cutaway illustration of Big G. (credit: McDonnell Douglas) |

Big G’s denouement

In early 1969, Richard Nixon entered the White House and his administration began considering what the space agency would do after the Moon landings. A human mission to Mars was proposed in the summer of 1969 by the acting NASA administrator. It was quickly rejected by Nixon and his aides as too expensive. As a result, Nixon’s advisors and NASA officials shifted their attention to developing a new transportation system to low Earth orbit. Options included a modified Apollo, Big G, and a winged spaceplane referred to as a space shuttle.

| Because NASA anticipated a higher flight rate, the ballistic capsule was rejected in favor of a much more capable space shuttle. After four years of proposals, Big G was finally dead. |

The decision to build the space shuttle was contentious and convoluted, and White House officials opposed to what they thought would be a costly space shuttle system kept Big G in the running as a less expensive alternative even as late as 1971. According to John Logsdon in his new book After Apollo?, in August 1971 NASA Deputy Administrator George Low rejected a capsule design in favor of a smaller winged shuttle. According to Logsdon, the Big G was the leading ballistic capsule design at that time.

By October 1971, as the debate over a future space transportation vehicle raged, a special review committee considered the options. They included a ballistic recovery spacecraft and an unpowered winged orbital vehicle. Logsdon indicates that the Big Gemini proposal then under consideration was the nine-person spacecraft proposed in 1969. The Big G was a more conservative approach than a winged space vehicle, and the committee believed that it “would be justified only if a slow-paced manned spaceflight program were contemplated (2 to 4 manned flights per year).” Because NASA anticipated a higher flight rate, the ballistic capsule was rejected in favor of a much more capable space shuttle. After four years of proposals, Big G was finally dead.

According to an October 1970 Project RAND report, a modified six-man Apollo spacecraft could be developed for $1 billion. Big Gemini’s costs are stated by one source as $1.5 billion and by another as $3 billion. Although the fidelity of these cost estimates is hard to determine four and a half decades later, presumably the Apollo option, which required fewer modifications, was undoubtedly cheaper and could be estimated more accurately compared to Big G, which would have essentially been a mostly-new spacecraft. What also remains unclear is why by mid-1971 the modified Apollo option was apparently no longer under consideration by NASA while Big G was still in the running. Big G was more capable than Apollo, but it would have been more expensive to develop. But NASA officials recommended and Nixon ultimately accepted that NASA should develop a large winged reusable space shuttle. Big G soon faded into obscurity.