Building a better booster (part 2)by Jeffrey L. Smith

|

| Hercules would use their composites expertise to achieve the goals of the Air Force and Martin Marietta: increasing performance of the Titan IV by 25 percent and reducing the number of individual motor segments from seven on CSD’s design down to just three. |

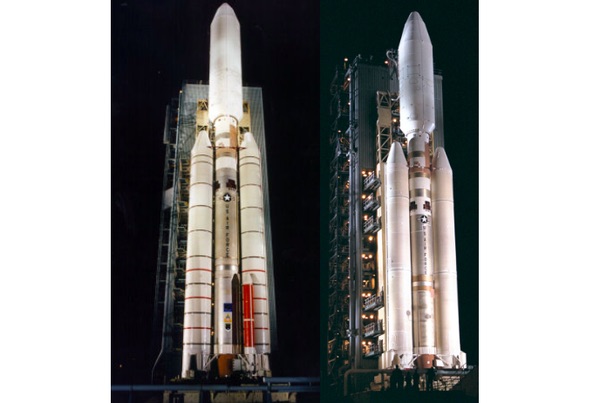

The shuttle had already been running late. In response, the Air Force created the Titan IV to launch just ten payloads in the late 1980s and early ’90s to bridge the gap until the shuttle was fully up and running, ready to take over defense launches. But, in the wake of the Challenger accident, the Pentagon decided the shuttle’s use to launch military satellites would be phased out. Worse still, the Titan IV was only sized to launch those ten payloads through the early 1990s: it wasn’t large enough to handle the growth of satellites already on the books for the late ’90s and beyond, since that was going to be a job for the shuttle. So, in 1987, two years before it would even reach the pad, Titan IV had gone from being the backup plan to the being only plan, and one that wasn’t going to work in the future.

Two years before the Titan IV’s first launch in 1989, prime contractor Martin Marietta proposed the solution to the Air Force’s problem. In 1987, Martin Marietta announced that they would replace the solid rocket motors on future Titan IVs with new motors made by Hercules. The Chemical Systems Division (CSD) of United Aircraft (later United Technologies) had always been the provider for the solid rocket motors for the Titan III and Titan IV rockets with their UA120 (United Aircraft, 120-inch diameter) solid rocket booster. Instead, Hercules had proposed the Solid Rocket Motor-Upgrade (SRMU), an update with modern technology to produce a new, low-cost and high-performance replacement motor that would kill everyone’s birds with a single stone.

Shuttle SRB with Filament Wound Case (FWC) prior to testing in its black carbon composite glory. Midbody white portion is a steel section for the Shuttle External Tank attachment (credit: NASA) |

Utah-based Hercules was in the military solid motor business with extensive experience in composite materials and they were looking to diversify into the space launch business. As part of the original plans to launch the shuttle into polar orbits from Vandenberg Air Force Base in California, Hercules had already designed and built a lightweight carbon composite rocket motor case. The Filament Wound Case (FWC) would be built by Hercules, and then filled by Morton Thiokol with the same PBAN-rubber propellant they had been using for years on the shuttle and the same type of propellant used on CSD’s Titan boosters. The arrangement worked just great: both organizations focused on their their specialties and ground tests were successful. But, in the wake of the Challenger disaster, military launches from Vandenberg were canceled, and Hercules’ composite cases along with them.

After losing out on the NASA contract, Hercules saw their chance to one-up the competition by using their shuttle experience as the basis for a new generation of large rocket motors. Hercules would use their composites expertise to achieve the goals of the Air Force and Martin Marietta: increasing performance of the Titan IV by 25 percent and reducing the number of individual motor segments from seven on CSD’s design down to just three, thus eliminating the majority of joints that had led to the Challenger accident. In addition to their carbon composite cases, Hercules would now fill the cases themselves with modern, high-performance HTPB-rubber propellant. Hercules would also replace the liquid injection thrust vector control (TVC) that CSD had used on previous Titan boosters with an articulated (gimballed) nozzle like the kind Morton Thiokol used on the shuttle. For this initial contract, Hercules would deliver the first of 15 sets of motors in 1990, just three years away.

The new SRMU would only be half a foot wider and able to use the existing infrastructure launch pads, etc. Titan’s Centaur upper stage and its RL10 engine were still in serial production (and still are to this day.) Best of all, the Air Force had already decommissioned the nuclear-tipped Titan II ICBMs that formed the core of Titan IV. But rather than sending the unused missiles to the scrap yard for recycling, the Air Force had carefully preserved them in California warehouses. The eyes of defense planners gleamed with visions of up to 100 Titan IV launches. It would take decades to launch all the rockets envisioned. Martin would lock up the defense heavy-lift market for another generation or even two. The Air Force would save a bundle using ICBMs that had already been paid for and they could show Congress and the American people a real peace dividend as ICBM swords were beaten into space rocket ploughshares. Hercules would diversify from the feast-or-famine weapons market to the smooth-and-steady defense space launch business. Best of all, Martin’s more than $500 million contract with Hercules was part of a new breed of commercial, firm-fixed price contracts that would bring competition to defense procurement and save billions of dollars: after all, it was commercial. The plan was perfect. All that was needed was Hercules’ new rocket motors. What could possibly go wrong?

Quite a bit, it turns out. In order to achieve the 25 percent increase to launch performance, Hercules had to include a number of new technologies they weren’t familiar with. Of course, they had lots of experience with lightweight composite cases, having built the ones for the shuttle. Also, when replacing Titan’s liquid injection thrust vector control system with an articulating nozzle, they turned to Moog, the subcontractor for the same system on the shuttle. However, these motors would be significantly bigger than anything in Hercules’ past and they lacked experience with segmented solids that both CSD and Thiokol had earned working on Titan and shuttle respectively. Solid rocket motors that are poured in separate pieces and then assembled at the launch site are significantly more complex than single-piece motors with additional joints and passages were the propellant can burn. Finally, in order to achieve the needed performance, Hercules would switch from a PBAN-rubber like the ones CSD and Thiokol were using for Titan and Shuttle, to an HTPB-rubber. This would allow the propellant to be denser and have more energy in the same-sized space. But, processing HTPB is very different from PBAN.

| Every new program is generally allowed a maximum of one piece of “magic”: that special step or piece of new technology which will make the whole thing work. Hercules had taken on three major risks. |

All rubber comes in a liquid that has to be mixed with a curing chemical before it hardens in a mold into its final form: car tire, rocket motor, and so on. PBAN, an “old” technology first used during the 1950s for the Minuteman ICBM, needs the additional step of being heated in an oven above 130°F before the hardening reaction will start. This is very handy when you have to fill a Space Shuttle SRB mold with more than 30 individual bowls, each filled with 10,000 pounds of propellant: you can stop midway through the process on a Friday afternoon and pick up right where you left off on Monday morning. HTPB is more like the “five-minute epoxy” from the hardware store: once the chemicals are mixed, the reaction starts, oven or no oven, and it becomes a race against the clock to fill the mold before the rubber starts to harden. With small rocket motors, this isn’t really a problem, but filling a rocket mold with 300,000 pounds of propellant requires extensive planning with everything prepared beforehand. These were the largest motors Hercules had ever made and the largest HTPB motors anyone had ever made.

Anytime a program takes on the technical risk of using new technology they expect some problems to crop up. Every new program is generally allowed a maximum of one piece of “magic”: that special step or piece of new technology which will make the whole thing work. Successful program managers know that piece of magic is going to be a source of problems, so they limit their risk and hold back a little extra time in the schedule and a little bit of money—management reserve—so they can assign extra people and resources to fix problems when things go wrong. Try to do too many new things and you simply run out of experienced people, money, and time to fix all the problems. This is what leads to programs getting cancelled for cause.

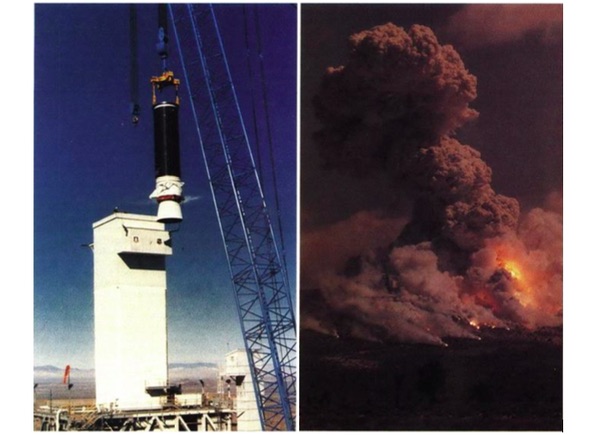

Hercules had taken on three major risks: switching to a trickier HTPB propellant, casting the largest motors they had ever made, and making segmented solids for the first time. Of course, Martin Marietta and the Air Force knew all of this and had still gone along with the whole scheme. It wouldn’t be long before each of these risk items would derail both the SRMU and the rest of the Titan IV-B program. In December 1989, Hercules lost the second segment they cast because it didn’t properly stick to the walls of the case, along with its 200,000 pounds of propellant. Officials said the loss wouldn’t delay the schedule. By September 1990, Hercules had recovered from the lost segment and was ready to test the first live rocket motor. But, while the motor was being stacked at Edwards Air Force Base, the crane dropped a segment. It rolled down the hill and burst into flames. The accident killed one person and injured nine. Officials said the loss wouldn’t delay the schedule. Finally, in April 1991, a year after the first motors were supposed to be delivered, Hercules was just barely getting ready to test fire the first SRMU. But Hercules hadn’t properly accounted for the extra burning surfaces of a segment motor and it exploded just after ignition. Officials said the loss would only “temporarily” delay the schedule.

SRMU being assembled prior to test at Edwards AFB (left). During the test, the motor failed and exploded (right). (credit: AW&ST) |

The SRMU would eventually lift the Titan IVB, but it would be seven years late, and in the end, no one won. The commercial Hail Mary that was going to improve Titan IV’s performance while lowering its cost took a decade to reach the launch pad, and by then, the EELV competition to pick the Titan IV’s successor was already in the works. Hercules had proposed a solution that couldn’t be implemented at the promised price, and Martin Marietta had accepted the optimistic claims in the hopes of reinvigorating their premier rocket. As nasty breakups often do, the two sides ended up in court, both blaming the other for their woes and mistreatment.

| If bailing out a rocket company is expensive, bailing it out while still paying its competition is even more expensive. |

At this point it didn’t matter, though. Neither would survive the decade as an independent company: Martin Marietta would be merged to form Lockheed Martin, while Hercules and, later, Thiokol would be absorbed into ATK. The Titan IVB would only fly a total of 17 times from 1997 to 2005, just two more flights than the original contract for 15 motors. A healthy rocket program flies for 20 to 30 years. Any longer, and the experienced veterans are no longer around to pass along their knowledge. Any shorter, and it doesn’t give time to work out the bugs or indicates the rocket was not a good fit for its intended market. Titan IVB had lasted just eight.

But, by the mid-1990s, the Air Force and NASA had designed payloads specifically around the Titan IVB’s promised performance. The program had become too big to fail, and so, it got its own government bailout to the tune of $350 million. Instead of just the 10, an additional 12 SRBs would be ordered from CSD to keep Titan IVA flying during the wait for the SRMUs. If bailing out a rocket company is expensive, bailing it out while still paying its competition is even more expensive. It had become clear that neither the shuttle nor recycled 1960s-era rockets were going to be the solution to the Air Force’s future launch needs, which prompted the EELV competition. The heavy-lift crown would go to the Delta IV Heavy, which first launched in 2004. Titan V was not selected. Gone were the dreams of launching 100 Titan IVs. This time, the remaining missiles were sent to the scrapyard and destroyed.

Even after the Challenger accident had put an end to any hope of flying military payloads from California, NASA still wanted an improved booster to launch large payloads for their future space station. This time, they turned to the last remaining rocket manufacturer to get an advanced booster, Aerojet. The Advanced Solid Rocket Motor (ASRM) would use modern HTPB propellant, but would eschew composites in favor of a traditional metal case. But, in the first three years of the program the schedule had already slipped almost a full three additional years, and the price had doubled. Before any rockets were fired, the project was cancelled. Instead of adding performance to the shuttle to reach Mir and the International Space Station, NASA would remove weight anywhere they could, lightening everything from the shuttle’s external tank to the very seats the astronauts sat on: anything to keep from touching the SRBs. In the US, wide-spread use of high performance solid boosters like the SRMU would have to wait another generation.

A display at Pima Air & Space Museum is the final resting place for some of the FWC hardware. The crosshatch pattern is the individual tows of composite fibers, painted white to resemble a metal Shuttle SRB. The nameplate still bears the names of Thiokol and Hercules. (credit: author) |

How can two rocket programs, GEM 63 and SRMU, run by versions of the exact same company, turn out so completely differently? After all, the temptation to underbid on cost or overpromise on performance in order to win a lucrative contract is just as great today as it was three decades ago. Both times, a Utah company beat out its California competitor by promising to reduce prices while also improving performance. Both times, tight timelines forced a blistering schedule. Both times, some of the same people, in the same place, used the same technologies, but to drastically different results. The difference wasn’t one of technology, but instead one of philosophy. The results were different because they think different. For that, they could thank an automotive engineer born half a world away.

Taiichi Ohno: Big in Japan

The 1980s saw a Japanese cultural invasion in the United States. A rapid improvement in industrial prowess since World War II allowed the Japanese to seemingly appear out of nowhere as a world economic leader. Japanese culture served as the basis for great 80s pop songs and the dramatic change in manufacturing quality produced fantastic time-travelling comedy between Marty McFly and a bewildered Doc Brown who was used to low-quality Japanese products in the 1950s. One area where Japanese industry excelled was in making high-quality, low-cost automobiles. The man credited with creating this automotive revolution was Toyota’s Taiichi Ohno.

Taiichi Ohno revolutionized automobile manufacturing for Toyota in Japan. (credit: Toyota) |

Taiichi Ohno worked in Toyota’s automobile division after World War II. Japan’s postwar economy was in shambles. The wartime scarcities had only worsened with devastating attacks upon Japanese industry. With his people’s situation so dire, Ohno began to see wasteful business practices not just as an increase to costs, but instead as morally reprehensible: every defective product, every unneeded item that went unsold represented food for hungry mouths or shelter over someone’s head. The elimination of waste, wherever it may be, became a veritable religion for Ohno and the Toyota Motor Company. Toyota would have to learn to do more with less.

| Much as the “traditional” automotive industry did in the 1980s and ’90s, the “traditional” aerospace industry is responding to new competition by adopting these same principles and adapting them to their own company cultures and situations. |

Ohno and his acolytes sought to eliminate “muda” (waste) in all its forms. Why was a worker standing around waiting for a part to assemble into a car? It wasn’t the worker’s fault he was wasting time, it was the part’s fault, and a system would be devised to make sure that part would always be ready, right when the worker needed it, so as not to waste even a moment. Why were 100 cars produced this week but only 50 of them were sold? The unsold cars represented waste and half the workers needed to be reassigned to other activities because they were making more than the market demanded. Over time small, imperceptible improvements led to massive gains that surprised the world. These principles were codified as the Toyota Production System.

The power of this system caught American car manufacturers off guard. Toyota was “disrupting” the automotive market with innovative manufacturing and quality control processes long before that term found a home in Silicon Valley. Ford had once been the disruptor itself with its legendary Model T. But they, along with the rest of Detroit, had to play catchup to a new way of thinking and a new way of doing business.

However, competitive technology and business practices can be learned by others, copied and even improved upon. New terms entered the US automobile industry like Just In Time, Kanban and Lean Manufacturing. Detroit learned to do more with less. While each auto company adopted these principles, that didn’t mean they slavishly copied Toyota. Ford didn’t start building Camrys (the most popular car in America), but instead kept making F-150s like they always had (the most popular of all vehicles in America). Similarly, the other American car manufacturers applied these principles to their existing products to streamline operations, reduce costs, and deliver new vehicles to market more quickly.

The automotive industry wasn’t the only one to notice great improvements by adopting lean techniques. While the Toyota Production System was focused on optimizing manufacturing, the same principles can be applied to the engineering side of the business. The concept of “lean manufacturing” was percolating in American industry in the 1980s and 1990s, and these ideas would then bubble up in the software industry during the 1990s and 2000s. When applied to software specifically, and the engineering process in general, this methodology is known as Agile Development. Agile development took root in the tech world of Silicon Valley, and from there spread to companies that have entered the space industry over the past two decades. Much as the “traditional” automotive industry did in the 1980s and ’90s, the “traditional” aerospace industry is responding to new competition by adopting these same principles and adapting them to their own company cultures and situations.

Transport trailer for GEM 63 and GEM 63XL. (Credits: NGIS) |

One example of eliminating unnecessary production processes is in the transportation and storage of the GEM SRBs. Traditionally a complete set of SRBs (called a ship set) is transported to the launch site in either Florida or California well before the launch and stored with plenty of time before it’s used, just in case. Now, Northrop Grumman Innovation Systems (NGIS) has developed special transport trailers that can ferry either a GEM 63 or 63XL directly to the launch pad where it is lifted directly from the trailer and attached directly to the rocket, just in time for launch.

One can almost hear the ghost of Taiichi Ohno asking very pointedly, “Are you in the rocket storage business or the rocket launching business? Why are you building the rockets too early and then letting them sit in a warehouse where they could be damaged? How much does that warehouse cost to rent? How many people have to spend their time maintaining the building and making sure the rockets are safe? Why don’t you eliminate the warehouse entirely and put those people to work doing something more useful for the company, more useful for society?”

AJ-60A being hoisted onto the side of an Atlas V. A GEM 63 can be lifted directly from the transporter trailer and attached to an Atlas V or Vulcan. (Credit: NASA) |

NGIS has also re-examined the entire rocket motor and looked for savings in everything from where to buy vital chemicals to each process in how the motor is made. Traditionally, a rocket goes through a complex process of winding the fibers around the mandrel, sending it to the oven to cure, and then performing ultrasound to ensure the case is good. Then the insulation is put on, followed by another ultrasound to make sure they are properly bonded together. The case is filled with water to make sure it will hold pressure before it finally gets filled with propellant and then baked in the oven. The filled case is X-rayed to make sure no voids (bubbles) formed or other unintended debris found their way into propellant. Only then is the motor ready to receive its nozzle and be sent to the customer for storage.

| The magic step this time around is that there is no magic technological leap, just continuous refinement and optimization of existing technologies to lower prices and speed up the time to market. |

In an effort to reduce cycle times and speed delivery to the customer, the company has combined steps and eliminated redundant processes. The insulation is now laid on the mandrel first and the composite fibers are directly wound on top before going to the oven to cure together. Ultrasounds are eliminated entirely and the case goes directly to be filled with water to ensure it will hold pressure. The propellant is poured, baked in the oven, and X-rayed only once. The nozzle and igniter are assembled before being sent to the customer for direct assembly onto the rocket, and then launched into space.

Traditional aerospace companies have learned how to do more with less, and they are continuing to improve. At the height of the shuttle program, ATK employed more than 6,000 in Utah, but today it’s down to around 1,400. And yet, they still support a rich mix of defense, civil, and commercial customers.

However, the drive for efficiency is a sword that cuts both ways. Even though NGIS was awarded the sole contract for SRBs, they lost their position making composite structures for ULA’s Atlas and Delta rockets. Instead, ULA chose Ruag Space, which already makes some of the composites for Atlas V, as the sole provider for Vulcan.

Left to right: subscale motor case; full scale motor case; full scale motor case filled with inert propellant. (Credits: NGIS) |

Eliminating manufacturing steps and reducing time to market doesn’t mean engineering rigor is reduced. In fact, it should mean just the opposite. Unnecessary steps are removed in favor of the most vital steps. Engineers make decisions based on only high-quality information, uncluttered by low-quality or ambiguous test data. Instead of making wild gambles that risk the company, knowledge is built upon, step by step, and risk is carefully managed.

Rather than risk the company with a repeat of Titan IV’s SRMU today, NGIS isn’t promising the highest-performing, lowest-priced rocket using brand new and untested technologies. Instead, NGIS is refining the technologies they already know so well and finding new ways to lower costs for both the GEM 63 and OmegA programs. The development of the OmegA’s Common Boosters Segments (also destined for SLS) has been a steady, multi-year march of reconstituting their large composite case know-how, first with subscale hardware and then at full scale. Full-sized cases are then filled with inert propellant, replacing the ammonium perchlorate with a non-reactive substance to ensure manufacturing processes produce the expected results. Only then, once all the bugs have been ironed out at each stage do they proceed to producing full scale, live motors.

The magic step this time around is that there is no magic technological leap, just continuous refinement and optimization of existing technologies to lower prices and speed up the time to market. At the end of his career, Taiichi Ohno still built cars with four wheels. But those cars had been refined by thousands of engineers and technicians over decades to completely change what we expect from a modern automobile.

Conclusion

The space launch industry is experiencing a period of change as politics and new entrants have made the market much more competitive. Traditional aerospace companies are responding to this new environment with new products and news ways of doing business. A generation ago, organizations like Hercules and Martin Marietta bet their companies with unfamiliar new technologies and unachievable schedules—and fell short. But today, their successors, companies like NGIS and ULA, are following a disciplined approach to product development with reasonable schedules, and succeeding.

All of this is evidence for a maturing rocket industry, one where new entrants and traditional rocket companies alike can bring in new ideas to create new markets and better serve existing customers. By taking a page from the automotive playbook, traditional aerospace companies are learning to be more efficient, lowering costs while speeding their products to market. By adopting lean manufacturing and agile development philosophies, traditional aerospace companies are adapting their know-how to compete in the new space marketplace. The successful test firing of the GEM 63 is an excellent example of this, going from contract to real space hardware in just three years. Taiichi Ohno would be proud.

But he’d say there’s still room for improvement.

Note: we are temporarily moderating all comments subcommitted to deal with a surge in spam.