The case for smaller launch vehicles in human space exploration (part 1)by Grant Bonin

|

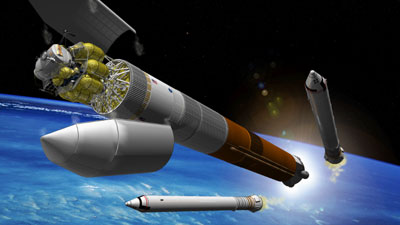

| Any human expedition beyond Earth will necessarily mass hundreds of tonnes initially, and since bigger boosters can carry much larger amounts of payload in far fewer launches, they have been championed by a majority of astronautical engineers as the most cost-effective way to shoot for the stars. |

Events such as the continuing war in Iraq and the devastation wrought by Hurricane Katrina have only increased the general political reluctance to endorse NASA’s new plan—and the pot isn’t sweetened at all by the prospect of using decades-old, hybridized space shuttle hardware as a basis for the future of human spaceflight. While many are adamant about heavy-lift technology being an absolute necessity for both lunar and Mars exploration, others nevertheless contend that bigger boosters only represent bigger failures in economic judgment, and that, if space exploration using HLLVs was truly cost-effective, the Apollo Saturn 5 would not currently adorn the grounds of Kennedy Space Center as a lawn ornament.

The question, then, is simply this: are heavy-lift launch vehicles the best technology for opening space to humankind? Or will attempting their development represent a costly dead end, the pursuit of which may dissipate the last wisps of confidence in America’s program of human spaceflight?

About this article

Building on economic arguments espoused by Wright [1] as well as studies into using smaller boosters for undertaking human expeditions to Mars [2], the goal of this essay is two-fold:

- To dispel the belief that heavy-lift launch technology is an economic necessity for human spaceflight; and

- To demonstrate the feasibility (both technically and economically) of undertaking human space exploration beyond low Earth orbit using existing, more modest launch systems.

While it is readily acknowledged that HLLVs will be the ideal technology when a demand exists that equals their potential, that demand does not yet exist, nor can it be seen on the horizon. In today’s economic climate, the need for massive boosters requiring massive spending may figuratively and literally be anchoring human space exploration to the ground. It needn’t be so.

A closer look at the bottom line

Advocates of heavy-lift launch systems generally talk about two key economic features which HLLVs possess and smaller vehicles don’t: high payload fraction, and fewer required launches per unit mission mass. (Non-economic issues, such as failure risk, will be discussed later.) Payload fraction is defined as the ratio of a launch vehicle’s useful payload mass to its gross weight at liftoff. By this metric, bigger boosters can be regarded as extremely effective compared to smaller launch systems. Heavy-lift vehicles can deliver a lot more payload to orbit for a given takeoff weight, and since weight is essentially the currency of spaceflight, this feature alone appears to be a good argument for their use. The second item—lower required launch volume for a given mission mass—basically means that, in order to deliver a fixed amount of hardware to low-Earth orbit (say, 150 tonnes, the approximate starting mass of a human expedition to Mars), only one or two heavy-lift vehicles would be required to get the job done, as opposed to perhaps ten launches of a less capable launch system.

At first glance, both arguments would appear to make a strong case for HLLVs. Proponents argue that fewer launches result in less complex deployment scenarios for large spacecraft requiring orbital assembly, and that greater payload fractions denote better mass efficiency, which, to put it simply, translates to more bang for a space program’s buck.

| No amount of increased mass efficiency can make a heavy-lift launcher as cost-effective as increased demand would, and high demand is something that heavy-lifters currently lack. |

But let’s take a closer look at these arguments, starting with the contention that better payload fractions result in reduced launch costs. In reference [1], Wright observes that because the majority of a launch vehicle’s gross liftoff weight is in fact propellant (which costs an insignificant amount compared to other components), optimizing mass fraction alone does not, in fact, result in a more cost-effective system. It helps, to be sure, but not nearly as much as minimizing support infrastructure or personnel, neither of which HLLVs do. If payload fractions were really significant drivers in cost reduction, the Apollo Saturn 5 would not have cost $2 billion in inflation-adjusted dollars towards the end of its operational lifetime, nor would the space shuttle cost what it currently does (between $600 million and $1 billion per launch.) No amount of increased mass efficiency can make a heavy-lift launcher as cost-effective as increased demand would, and high demand is something that heavy-lifters currently lack.

The other contention of HLLV advocates—that low launch volumes increase mission effectiveness by reducing operational complexity—also permits different interpretations. Indeed, fewer launches mean fewer components that need to be pieced together on orbit, as well as less risk of mission-critical launch or assembly delays. However, issues of effectiveness and complexity permeate far more than just flight rates and assembly schemes. The overall launch system and its support infrastructure must also be considered when evaluating these characteristics, and since bigger boosters require far more personnel and far more elaborate facilities (and are themselves far more operationally complex), it is questionable whether or not “reduced volume” really results in reduced complexity, or better mission effectiveness overall.

To illustrate, one might compare the launch of 200 model rockets to the launch of a single Lockheed Martin Atlas 5. In spite of having an incredibly high volume, the model rockets are nevertheless much simpler to fly than the Atlas because they require far less in terms of operational support. Regardless of the launch rate, each distinct launch itself has to be considered in terms of what it takes to get airborne—and the bigger the launch system, the harder it is to get off the ground in the first place. The issue of complexity has far less to do with launch volume, and much more to do with launch infrastructure—and if this is used as a criterion for evaluating effectiveness instead of required flight rate, heavy-lift vehicles certainly lag far behind smaller ones.

Flight rate is indeed a key driver in launch costs, though not by virtue of the mechanisms typically suggested by heavy-lift advocates. The real costs in rocketry stem from capital and labor costs, which produce the opposite effects of what most heavy-lift backers contend. Because a huge amount of fixed capital exists to support any substantial launch system (in the form of launch pads, assembly facilities, etc.), costs are driven down not by decreased launch rates, but rather by increased launch rates. Large capital investments require high utilization in order to be profitable, and because larger rockets require larger capital investment, their characteristically lower launch volumes actually drive costs upwards (sky high, if you will). For a substantial capital investment, minimum cost will result from maximum use, not the reverse: if you’re going to invest in a big launch pad, it’s in your best interests to use it as frequently as possible [1]. The only sort of launch systems for which lower flight rates are economical, therefore, are actually smaller boosters, and even then, similar economic arguments apply, making higher usage much more desirable in terms of cost amortization.

| For a substantial capital investment, minimum cost will result from maximum use, not the reverse: if you’re going to invest in a big launch pad, it’s in your best interests to use it as frequently as possible. |

But these arguments only speak to capital investment; labor costs are also a significant consideration. Heavy-lift boosters require far more personnel for operation and maintenance than smaller launch systems, and because of their characteristically lower launch volume, a larger number of workers will have to be paid far more per flight (which, admittedly, is just fine if you happen to be such a worker). Conversely, a smaller launch vehicle will require far fewer support personnel, who (if paid comparably to the heavy lift team) will be able to work on a much smaller per-launch budget. It gets better. Since the smaller team for the smaller launch vehicle will be firing off a much greater number of boosters per year on average, they will also become much more practiced in their jobs. Wright [1] observes what economists call the “learning effect” here: a task performed twice as often will typically improve efficiency by 10–20%. It makes no sense to staff a huge car factory with hundreds of workers, only to produce a handful of units per year: those workers would get rusty (no pun intended) at what they do anyway. A smaller team that does their job more often can be expected to stay sharper, and will correspondingly exhibit higher performance in general (for much less money per flight).

So once again, we find that higher flight rates promote effectiveness, not the reverse. And while advocates of heavy-lift boosters, such as Robert Zubrin, often evoke arguments based on the economics of scale to promote larger launch systems, the aerospace industry at large has not yet experienced any such benefits, even in such high demand areas as civilian air travel. While larger jets can carry far more passengers, the variation in economy per seat-mile between big and small aircraft is actually quite small: civil flight economy scales much more powerfully with flight rate than vehicle capacity alone. Interestingly, this is the apparent basis for Boeing’s choice to shift emphasis towards developing smaller vehicles such as the 787 Dreamliner, which will carry fewer passengers per flight but enjoy larger flight rates than such behemoths as the Airbus A380. While A380 will need more support infrastructure than Dreamliner, and will only be able to service the most major of flight routes, it will nevertheless be competitive because a number of such major routes exist. However, no comparable argument exists for space launchers: there simply isn’t enough volume demand to truly make heavy-lift vehicles economical, nor is there likely to be for quite some time.