Engineering Mars commercial rocket propellant production for the Big Falcon Rocket (part 3)by Steve Hoeser

|

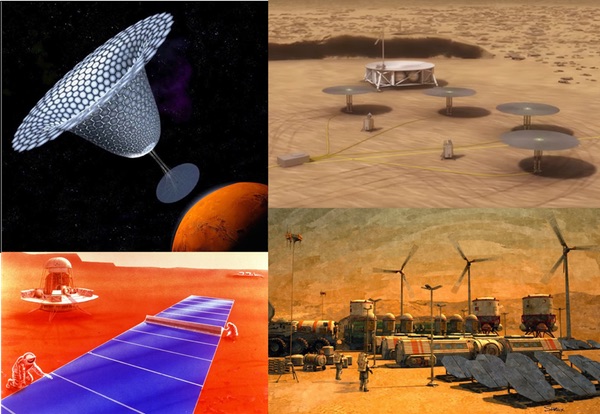

| Sources of electric power on Mars in the near term include solar, wind, nuclear, or a combination. |

Determining the continuous power needed is the initial basis for setting the power production requirement. Let’s assume the propellant production plant and associated resource operations need to produce the propellant for a single Big Falcon Rocket (BFR). Further assume that the BFR will only launch during optimal minimum energy orbital alignments between Earth and Mars. This means that the 16 gigawatts can be spread over roughly 26 Earth months. So, for every hour of operation, the plant and associated water ore and refining systems will require just under one megawatt (MWe) of continuous electric power.

Sources of electric power on Mars in the near term include solar, wind, nuclear, or a combination. Let’s take a closer look at these to assess each candidate’s performance and economic acceptability to meet the BFR propellant production operational need.

The options

Power generation options come in several forms:

- Radioisotope Thermoelectric Generators (RTGs) like those used on Voyager and other deep space and Mars missions;

- More conventional nuclear fission reactors like the Space Power or SP-100 fission reactor concept or more recent Kilopower fission reactor concepts;

- Non-nuclear options such as solar and wind power; or

- One of the various as yet to be demonstrated fusion power production options.

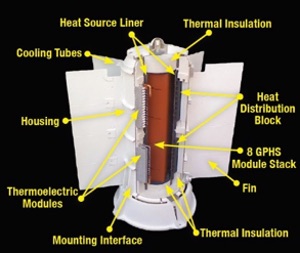

RTGs, though having safety concerns and political issues, have a well-established technology base. The RTG falls in a family called radioisotope power systems, or RPS. These RPS provide electricity and heat that enable spacecraft to undertake scientific missions to environments beyond the practical capabilities of conventional solar power, chemical batteries, and fuel cells.

RPS are sometimes referred to as a type of “nuclear battery.” While some spacecraft, like Cassini, do run their systems directly off of their RPS, others like the Mars Science Laboratory rover can use the RPS to charge batteries and run their systems and instruments off of stored battery power. In either case, the RPS is attached directly to a spacecraft or planetary system, much like a power cord being plugged in.1

These technologies are capable of producing electricity and heat for decades under the harsh conditions of deep space without refueling. These power systems have flown on more than two dozen NASA missions since the 1960s. All have functioned for longer than they were originally designed.

The design of an RTG is simple by the standards of nuclear technology. The main component is a sturdy container of a radioactive material. Thermocouples are placed in the walls of the container, with the outer end of each thermocouple connected to a heat sink. These thermocouples are thermoelectric devices that can convert thermal energy directly into electrical energy. Radioactive decay of the fuel produces needed heat. It is the temperature difference between the fuel and the heat sink that allows the thermocouples to generate electricity.

Unfortunately, though simple and reliable, these RTGs do not produce the kind of power that will be needed for propellant production. NASA’s multi-mission radioisotope thermoelectric generator (MMRTG) is designed to produce only 125 watts electrical power at the start of mission, falling to about 100 watts after 14 years.2 With a mass of 45 kilograms, the MMRTG provides about 2.8 watts per kilogram of electrical power at beginning of life.

Design of an RTG. (credit: NASA MMRTG Fact Sheet) |

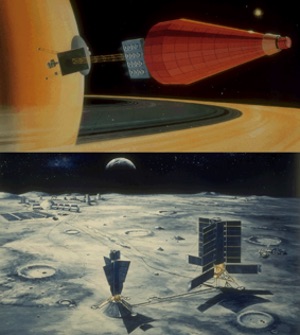

Fission reactors: A number of fission-based reactors have been studied in the past, and some have more recently been reconsidered. In a 2011 NASA Small Fission Power System study for planetary science missions, power-to-mass capabilities between 1.2 to 1.7 watts per kilogram were projected. In a February 2016 paper presented at the Nuclear and Emerging Technology for space, a low enriched uranium (LEU) ceramic-metal (CERMET) based space fission surface power source design was projected to provide 333 kilowatts, with a lifetime of 15 years without refueling.3

| If positioned in the correct location, ground-based solar arrays might function just as well, if not better in some cases, than the nuclear options. |

In the late 1980s, DARPA, the Department of Energy, and NASA/JPL investigated designs for a fission reactor called the SP-100. The objective of the SP-100 program was to develop long-lived, compact, lightweight, survivable nuclear reactor space power systems for application in the power range 50 to 1,000 kilowatts. With General Electric as the prime contractor, the reactor design progressed and tests were conduct until the program’s funding was terminated, primarily due to public political pressures. The reactor mass for a 100 kilowatt unit was projected to be around 5,422 kilogeams. Potential applications included powering military satellites, propulsion systems for spacecraft and planetary bases.4,5

Concepts for space-based nuclear reactors. (credit: NASA & Kulsinski, G) |

More recently, NASA’s Space Technology Mission Directorate has been re-investigating the use of fission power as an alternate way to provide higher space power levels and for deep space missions far away from the Sun. These systems, designated as Kilopower units, would provide between 10 to 40 kilowatts of power each continuously for at least ten years without refueling.6 The first 10-kilowatt Stirling units would be approximately four meters tall and weigh about 1,800 kilograms with performance of about 5 watts per kilogram. A concept for a 40-kilowatt unit would weigh between 5,800 and 7,000 kilograms and be 10 meters tall and 34 meters in diameter with radiators deployed.7 Work on the Kilopower project to date indicates that it may be possible to scale it to a “Megapower” project, producing units with an output of up to two megawatts.

A prototype of this power system has been designed and developed by NASA’s Glenn Research Center in collaboration with NASA’s Marshall Space Flight Center and the Los Alamos National Laboratory. The reactor core was provided by the Y12 National Security Complex. NASA Glenn shipped the prototype power system from Cleveland to the Nevada National Security Site (NNSS) in late September 2018. Testing took place from last November until earlier this spring.8

Features of this reactor would include reactor self-regulation, low reactor core power density, and the use of heat pipes for reactor core heat removal. The reactor would be attached to an open air Brayton cycle power conversion system using air as the working fluid and as the means of ultimate heat removal. The reactor would weigh about 40 tonnes, including three tonnes of low enriched uranium fuel (16–19 percent enriched).9

Assuming a Kilopower-based power plant for Martian propellant production, 100 ten-kilowatt or 25 forty-kilowatt units would be required to provide the continuous one megawatts of electricity. The ten-kilowatt reactors would weigh 180 tonnes, while the 40-kilowatt systems would conservatively come in at around 175 tonnes. Adding 20 percent for associated power conditioning power support subsystems and possibly heat pipes (to exploit the reactor heat for plant thermal requirements), the total fission transport and emplacement mass totals between 210 and 216 tonnes. This means that at least two BFRs will be needed for transport to Mars and any associated emplacement systems.

Solar options: In a presentation in October 2008 at the International Astronautical Congress in Glasgow, MIT engineer Wilfried Hofstetter compared the power-producing capabilities of nuclear fission reactors, RTGs, Sun-tracking solar panel arrays, and non-tracking thin-film solar arrays laid atop the Martian landscape. The study concluded that, if positioned in the correct location, ground-based solar arrays might function just as well, if not better in some cases, than the nuclear options.10

Solar power sources include solar arrays on Mars itself or emplaced in space as solar power satellites around the planet. Each has its own benefits and challenges. These include keeping ground-based solar panels clean of dust, the reduced intensity of the sunlight compared to Earth because of Mars’s distance from the Sun or masking due to dust storms, and the cost to establish large solar power arrays or satellites and their large receiving antennas (rectennas) on the surface of Mars. There is, of course, the same issue of loss of power generation during nights for surface solar power arrays.

Ground based Arrays: According to Hofstetter, a Mars mission should be able to transport several lightweight two-meter-wide rolls of thin-film solar panels for a groundbased array. He contends that rolling out an array of thin-film rolls at latitudes of up to 40 degrees north of the Martian equator (southern latitudes have much less solar energy available for most of the year) could supply energy to a base.

The key governing the design and sizing of a ground based solar cell power system is its performance on Mars. The performance is driven by the reduced radiant flux (compared to Earth or space-based) from to the added distance from the sun and Martian atmosphere.

Mars only receives a flux power of about 593 watts per square meter from the Sun. If we assume one megawatt as the needed power, the calculation to estimate how much power a given area of solar panels will output is:

E=AϵFrp

where E is the energy in watts, A is the size of the solar panel, ϵ is the efficiency, F is the flux received, and rp is the “performance ratio” of the solar panels (losses due to shading, dust, circuitry, etc.)

| So, for a trip from Earth to Mars, a single BFR (after being refueled in low earth orbit) would be able to transport this type of solar power system to Mars. |

The blanket power density efficiency of thin-film solar panel arrays is about 684 watts per kilogram for low-cost advanced silicon cells on stainless steel foil. In 2016, Ascent Solar Technologies, Inc. announced it had achieved a major breakthrough in power-to-weight ratio for its superlight solar module, delivering over 1,700 watts of power per kilogram, operating in the space environment. However, the power density jumps to 2,440 watts per kilogram for 1 mil Kapton polymer for demonstrated higher cell efficiencies (10.7–12 percent.)

The MIT researchers also calculated it would take two astronauts 17 hours to construct such an array. Alternatively, they could get a robotic system, like that being developed by OffWorld, to do it. So adequate system deployment solutions exist and this should not be a design issue.

In this review of propellant production plant power options, it is assumed that the arrays are positioned at 25° north. If we assume that we have the highest solar array efficiency of 12.5 percent performance ratio, this equation can be solved to see the plant’s solar array area would be just over 56,200 square meters, or about 0.06 square kilometers. For comparison, a football field is about 5,000 square meters, so the ground based solar array would need to have a minimum starting total collection area equivalent to more than 11 football fields during the Martian day.

However for continuous day/night production, a power storage subsystem will be required. Power storage options include batteries and more exotic options, such as storage flywheels. For this review, rechargeable batteries are assumed for nighttime production due to their high maturity.

Batteries used during the night will need to be charged during the day. This means additional solar arrays that are dedicated to charging the batteries will also be needed. As an example of reasonably highly efficient rechargeable batteries, Tesla’s commercial power pack batteries each have an energy capacity of 210 kilowatt-hours (AC). These lithium ion battery packs also have a 100 percent depth of discharge and mass around 1,625 kilograms each.11

To transport and emplace just the propellant production solar arrays using the highest efficient power-to-mass ratio arrays (12 percent) would require transport of about 820 kilograms for the thin-film solar panel arrays to Mars. This is double the array capability for daytime operation to account for daily solar charging of batteries. It does not include the needed backup batteries, power conditioning and power support subsystems. If we add the mass of “Tesla Wall-equivalent” batteries for overnight operations, this increases the mass that will need to be transported and emplaced to just over eight metric tons. Even if this were again double, the power production system mass due to associated equipment, power conditioning, support equipment, and initial estimating errors, falls well within a single BFR Mars transport capability of 150 metric tons.

So, for a trip from Earth to Mars, a single BFR (after being refueled in low earth orbit) would be able to transport this type of power system to Mars. This indicates that the cost and life-efficiencies of a groundbased solar power system may dominate and need to be investigated in more depth.

Martian Solar Power Satellites: Solar Power Satellite (SPS) systems, based on wireless power transmission, have attracted attention since the 1970s. Most candidate solutions have been focused on the economic viability and competitiveness as power production alternatives for terrestrial electric power needs. However, more recently they have been considered as options to provide power to space vehicles or to elements on a planet’s surface.12

The SPS system is composed of three main parts: the power generation system (solar cells, concentrators or other); the power transmission system, including the conversion of electrical energy; and the generation of the beam. Both laser and radiofrequency (RF) transmission systems have been considered. Finally, the power receiver system, which is closely linked to the laser or RF technology used for power transmission.

| Mass requirements make the SPS a non-attractive power production option for the Mars propellant production facility. |

For a Martian application, the SPS is preferably located in an areo-synchronous orbit (17,000 kilometers altitude) in the Mars equatorial plane. RF power transmission is preferred, because size constraints on the receiver can be somewhat relaxed for this application while laser transmission is still penalized in case of dust storms. The SPS receiver could be located at a safe distance from the Mars propellant plant.

A direct scaling of Martian SPS concepts studied would project a satellite sufficient to generate 60 megawatts with an antenna emitted power of 20 megawatts. Assuming an attenuation and collection efficiency of just over 10 percent, the power received at the receiver system would be just over two megawatts. This would produce the needed one megawatt of propulsion plant power.

Such a system would have a total system mass, based on scaling, of 5,000 tons. With such a large mass, more than 33 BFR launches would be needed for low Earth orbit emplacement. If the Martian SPS were assembled in LEO, it could use solar electric propulsion for a slow trip to Mars. The remainder of the SPS components would require additional BFR flights to refuel the BFRs transporting the ground antenna, power conditioning, and support systems. Such design requirements make the SPS a non-attractive power production option for the Mars propellant production facility.

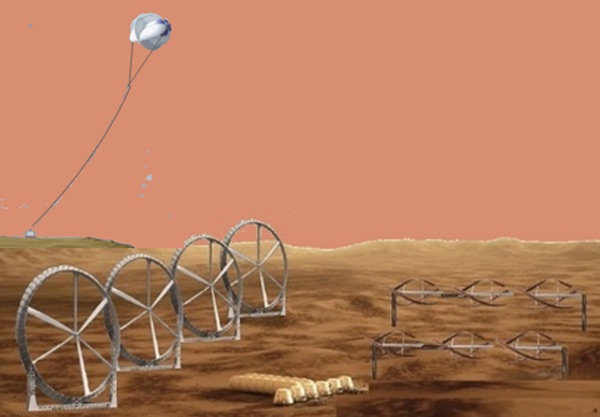

Wind power: The Viking landers offer some of the best-studied regions regarding Martian wind. Like the wind speeds of Earth, the average Martian wind speeds vary by season. At the Viking sites, the average wind speed registered at two to seven meters per second during the Martian summer. During the fall, the average wind speed increased to five to ten meters per second. The winds in the strongest Martian storms top out at more than 25 meters per second. This is less than half the speed of some hurricane-force winds on Earth. Across the year, the wind speed on Mars averaged ten meters per second.

However, when considering the potential for wind-based power production, focusing on wind speed can be misleading. The Martian surface pressure is very low because the planet has a very thin atmosphere. Earth has an average surface air pressure of 1,013 millibars, but at Mars it is only 7.5 millibars. This means that the atmosphere on Mars is only about 0.7 percent as dense as Earth's atmosphere, and thus the power production potential of the Martian winds are significantly less than on Earth.

According to Martian weather scientist David Bubenheim of NASA’s Ames Research Center, on Earth about 10 meters per second wind speed is needed to make electricity with wind turbines; on Mars about 30 meters per second is needed because of the extremely thin air.13 This requires special wind turbine design, especially for the blades.

These special Martian turbine designs would need to have very smooth blades to work efficiently in the thin atmosphere. These blades would likely be similar to those used in very high altitude aircraft, like NASA’s Helios, where the air is very thin. Also, consideration is needed in wind turbines to counter Martian dust that could stick to the rotor blades or abrade them. The inner workings of the turbine generator would also have to be protected from the dust infiltrating and damaging them.14

Proposals for generating power on Mars using the Martian wind. (credit: University of Houston & Magenn Power Inc.) |

In one concept study at the University of Houston, a Mars power system using solar and vertical axis wind turbine design was predicted to produce an average of 300 kilowatts per day. This system has a mass of 944 kilograms.15 Direct scaling to a one-megawatt system would require transport and emplacement of just over 3.15 tonnes.

Another innovative concept is to use a wind-turbine blimp such as the Magenn Air Rotor System (MARS).16 Instead of the large pinwheel or spiral blades that are typical of ground wind turbines, the blades of this MARS turbine are actually part of a three-dimensional blimp. The MARS blimp turbine attempts to take advantage of the fact that winds at higher altitude move significantly faster than low-level winds because they don't encounter as much resistance from objects on the ground.

The blimp turbine uses surface blades to catch the wind, causing the entire blimp to spin around. A generator converts that movement into electricity, which is transferred down the turbine’s long tether to the ground station. It should be lower in mass and thus have less mass transport and set-up costs.

Such a blimp-based power system might also take advantage of hydrogen produced in the propellant production process as the lift gas. With so little oxygen in the atmosphere, hydrogen should be a reasonably safe lifting gas.

| In the long run, it is likely that a combination of power options will emerge on Mars to serve Martian power needs. |

Fusion Power Options: In order for fusion power plants to be feasible, they have to produce more energy than they consume. It’s a challenge that’s confounded scientists for years. This key metric requires a net positive power in a reactor. Additionally, the majority of these reactor concepts are heavy. They also appear to be practical only in large power plants producing 100 megawatts or more.

Fusion power has been an elusive power production promise. Many have said that “fusion power is 20 years away” for more tan 30 years. This negative perspective ignores the progress made since the 1970s. However, even though greater understanding of practical fusion power production options has been made, for this review fusion is not considered practical for a Martian propellant production plant.

Finding the right combination

In the long run, it is likely that a combination of power options will emerge on Mars to serve Martian power needs. Bubenheim believes that “Wind power and solar power may complement each other on Mars. When you have a large dust storm blocking the sunlight on Mars, a wind turbine can still generate electricity.” Others advocate the long enduring and predictably reliable advantages of fission power like the NASA Kilopower concept.

The figures for power generation and power production systems presented in this review are presented only as system design options with rough initial ballpark system specification estimates. They are intended to help designers begin to scope the magnitude of the engineering challenge and place perspective on future Mars plans. Establishing any new frontier requires long and sometimes tenacious work to emplace such self-sustaining economic capabilities like propellant production and power systems.

In summary, the purpose of first order system engineering analysis it not to derive an optimized solution. Instead, it is used to provide a bounded understanding of the overall architectural scope, an enhanced insight of the preliminary system concept, and greater awareness of the supporting technological landscape. It is then left to the teams of dedicated engineers, managers, and financiers to ultimately take up the challenges of creating the needed system capabilities.

Like other settlements of the past, successfully providing sustainment commodities like Martian rocket transport propellant will be need to exploit ISRU capabilities. The considered management during the startup period of associated extra costs to emplace propellant production facilities is vital before ISRU can begin. However, once minimum operations begin, a gradual shift from imported propellant to full ISRU capabilities will ensue. Such ISRU capabilities will support an ever-growing Martian base whose independence from Earth, and other cislunar support systems, will ultimately be achieved.

Endnotes

- NASA Radioisotope Power Systems.

- Multi-Mission Radioisotope Thermoelectric Generator (MMRTG), NASA Fact Sheet, October 2013.

- Beyond NERVA, January 19, 2018.

- SP-100, The U.S. Space Nuclear Reactor Power Program, Program Technical Information Report, JPL D-1085, Vincent C. Truscello, November 1983.

- Sovie, Ronald J., SP-100 Advanced Technology Program, NASA Technical Mem, 89888, AIAA-87-9232, NASA/Lewis Research Center, Cleveland, OH, August 1987.

- NASA Glenn Research Center Fact Sheet: The Fission System Gateway to Abundant Power for Exploration.

- Nuclear Systems Kilopower Overview, NASA Space Technology Mission Directorate/Game Changing Development Program, McClure, P. & Robinson, R. presenters, February 22, 2016.

- NASA Glenn Research Center, Technology Directorate, Kilopower-related references.

- World Nuclear Association. Nuclear Reactors and Radioisotopes for Space (updated November 2017).

- Ian O'Neill, “Despite Dust Storms, Solar Power is Best for Mars Colonies”, November 20, 2008.

- Telsa Commercial Powerpack web site.

- C. Cougnet, E. Sein, A. Celeste, L. Summerer. SOLAR POWER SATELLITES FOR SPACE EXPLORATION AND APPLICATIONS.

- NASA Ames Research Center. ANTARCTIC/ALASKA-LIKE WIND TURBINES COULD BE USED ON MARS. Release: 01-72AR.

- M. Ragheb, Wind Power for Mars Mission, April 6, 2012.

- CONCEPTUAL DESIGN OF A MARTIAN POWER GENERATING SYSTEM UTILIZING SOLAR AND WIND ENERGY, Student Design Team: Amir Hemmat Chi Nguyen Bharat Singh Keir Wylie, Advisor Team: David Zimmerman, Faculty Advisor Ross Kastor, Design IV Instructor George James, Engineer-in-Charge, University of Houston, TX.

- Rakesh Chaudhari, Electric Energy Generation by Magenn Air Rotor System (MARS), IJCSN International Journal of Computer Science and Network, Volume 4, Issue 2, April 2015.