Low-cost launch and orbital depots: the Aquarius systemby Andrew E. Turner

|

| For this system to work, the consumables-only launch must be a lot cheaper than the launch of a high-value, possibly irreplaceable payload. |

As discussed here previously, the Aquarius system under development by Space Systems/Loral (SS/L) is built on this premise. (See “The myth of heavy lift”, The Space Review, May 17, 2004) The Aquarius launcher concept is a simple, low-margin, pressure-fed, floating-launched vehicle. Its design strategy allows mission reliability reduction to the extent that net delivery cost to orbit is minimized commensurate with the low intrinsic value of its one-ton payloads. SS/L has been developing this concept since 1998 and has been funded by customers to pursue it, with the concept receiving increasingly serious attention as it advances.

Addressing the American Astronautical Society on November 15, 2005, NASA Administrator Mike Griffin said “…specifically we should desire to place fuel in orbit by the cheapest means possible, in whatever manner this can be accomplished, whether of high reliability or not… if there were a fuel depot available on orbit, one capable of being replenished at any time, the Earth departure stage could after refueling carry significantly more payload… maximizing the utility of the inherently expensive SDHLV [Shuttle-Derived Heavy-Lift Vehicle] for carrying high-value cargo.”

Recent articles by Grant Bonin have touched upon this topic (see “The case for smaller launch vehicles in human space exploration”, parts 1 and 2, January 3 and 9, 2006). Mr. Bonin discussed the virtue of spreading payloads to be launched for Mars missions across multiple medium-sized launchers, instead of putting all the eggs in a single heavy-lift launcher basket and mentioned that this permits multiple types of launchers to be employed. Thus, a high-reliability, possibly heavy-lift launcher could carry the astronauts and high-value cargo, while a low-cost, reduced-reliability launcher would carry consumables and other low-value items. The entire Mars-bound system would not suffer if a few consumables launches failed, provided the consumables are launched in advance of need and maintained on orbital depots.

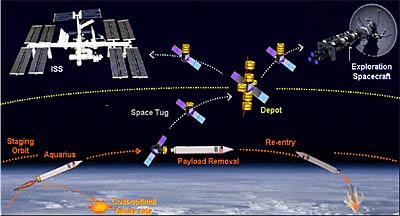

The International Space Station would also benefit greatly from the low-cost launch of consumables using an inexpensive, reduced-reliability launcher for ascent, and depot storage for orbital supply. Both low- and high-value cargo are required for the station. While the low-value cargo could be carried to orbit on Aquarius and the high-value items on other launch vehicles, the depot, itself a very reliable vehicle, would stock both low- and high-value items. A space tug would complete the system, ferrying supplies from the launcher to the depot for storage, and from the depot to the ISS when needed, as the diagram above shows.

Use of a depot permits the decoupling of launch from station delivery in a number of key dimensions. Launch schedules need no longer correspond to ISS delivery schedules, which constrains the number and length of stay of delivery missions to minimize impacts on mission science and astronaut time. Instead, consumables can be launched in advance of need and maintained on orbit at the depot. The number of launches need not correspond with the number of delivery missions: as the diagram indicates, canisters corresponding to individual launches could be grouped for delivery. Reliability decouples as well: launch reliability need not be as high as the reliability with which ISS delivery must be provided, since payloads can be launched in advance of need. Thus, the introduction of a depot would provide numerous advantages to reduce cost and increase flexibility for the delivery of supplies and equipment to the ISS.

An established Aquarius system could begin to support other spacecraft, including commercial satellites. Spacecraft could be launched dry and propellant supplied to them on orbit, thus permitting a wider variety of high-reliability launchers to be used, including launchers with insufficient payload mass capability to carry today’s large spacecraft when fully fueled. It would also permit the larger launchers to carry two dry spacecraft instead of one fully-fueled satellite, thus reducing launch costs. The reliability of existing launch missions could be improved by increasing the amount of propellant allocated to launch performance reserve, greatly reducing risk of underperformance, which is a major cause of launch mission failure. The net benefit to the commercial spacecraft businesses would be reduced launch cost and risk.

Low-cost propellant and other supplies would also be available to support new classes of missions including spacecraft with high and extended maneuverability, removal of orbital debris, the assembly of large-scale structures to serve as giant space telescopes, or platforms to beam solar power to Earth to bolster our country’s energy independence.

| An established Aquarius system could begin to support other spacecraft, including commercial satellites. The net benefit to the commercial spacecraft businesses would be reduced launch cost and risk. |

Low-cost microsats, or university-class spacecraft, would benefit greatly from the Aquarius system since low-cost microsats can be produced economically in greater numbers than are required for orbital use. If three copies of a given microsat were produced and then launched on three separate Aquarius missions, the probability of successful delivery of one of the three units would be better than 96% if Aquarius’ reliability was 0.67 and better than 99% if Aquarius’ reliability was 0.8. Dedicated launches of microsats could be performed, or there could be a mix of microsats and supplies carried on a single vehicle. A mixed microsat/supply launch could be optimal to support swarms of microsats that provide distributed functionality, such as for a space telescope composed of multiple craft that would provide unprecedented magnification or resolving power due to the large separations between the component optical elements. In such a case, the supplies would be used to refuel a medium-size spacecraft that serves as a “mother ship” for the swarm, providing processing, orbit and attitude determination, power, and other support.

Thus, large-scale space activities can benefit from a reduced-reliability launch capability for low-value cargo. SS/L plans to pursue further demonstrations of low-cost system features that would become part of the Aquarius system of low-cost launch and orbital depots. The Aquarius system, or one similar to it, is expected to become a vital part of a sustainable infrastructure in orbit that would play a key role in realizing the President’s Vision for Space Exploration and enable greater, more cost-effective exploitation of space.